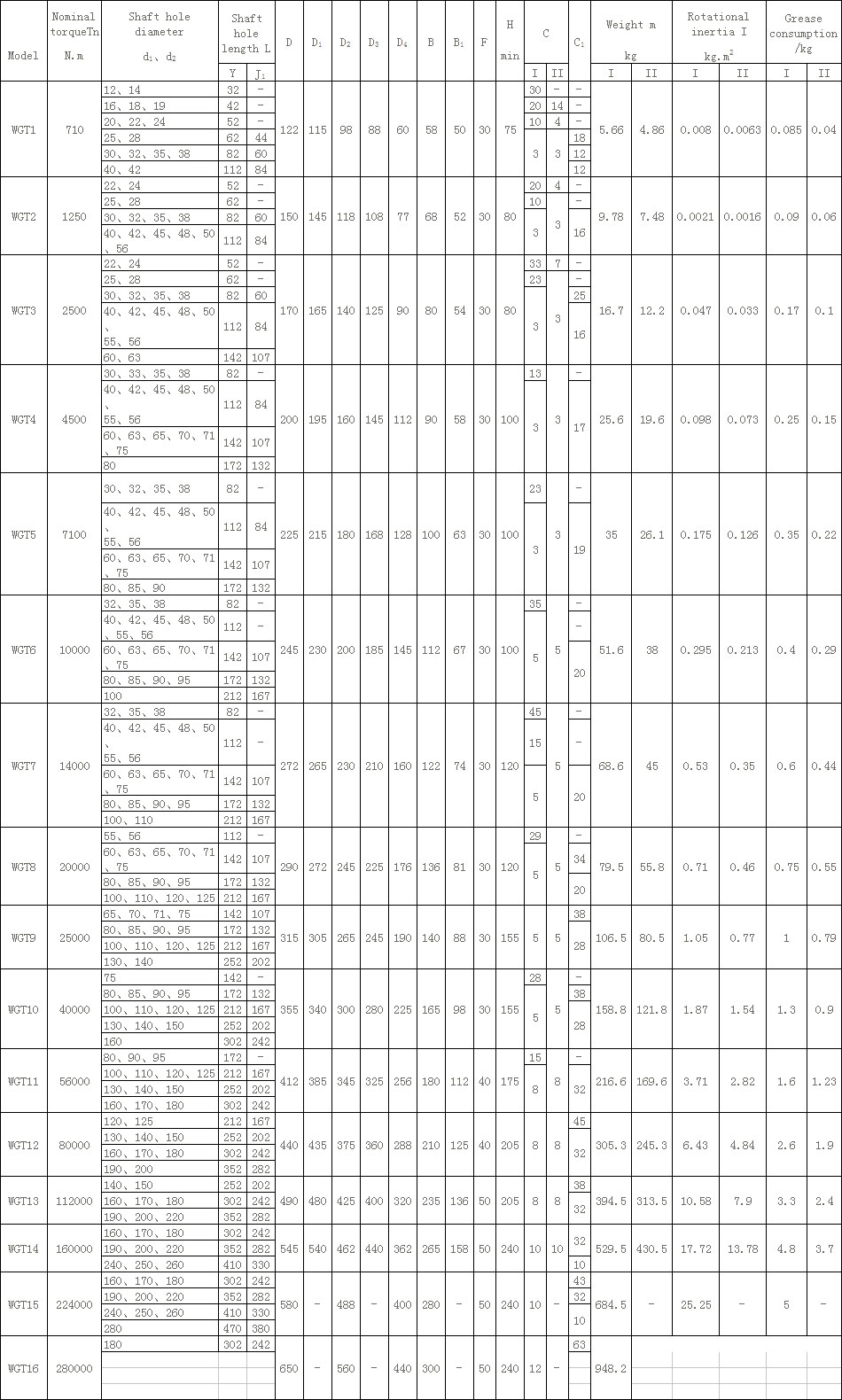

WGT type connecting middle sleeve drum gear coupling

Features and applications of WGT drum gear coupling: It has a small amount of axis offset compensation performance, and cannot buffer or reduce vibration.Small size, theoretically large transmission torque, need lubrication, sealing, but high noise, expensive, used to connect horizontal two coaxial line shaft transmission.Used to connect two horizontal coaxial lines under low speed and heavy load conditions, such as metallurgical machinery, heavy machinery, etc.It is not suitable for shaft transmission, and it is not suitable for the working conditions of frequent starting and changeable forward and reverse rotation.

WG type-basic type;

WGP type-with brake disc type, suitable for matching with point disc brakes;

WGZ type-with brake wheel type, suitable for matching with pad type brakes;

WGT type---connected middle sleeve type, suitable for long-distance connection of two shafts, the allowable speed [n] depends on the length and quality of the middle sleeve, and the critical speed should be checked;

WGC type-vertical installation type, used to connect the vertical two-axis shafting transmission;

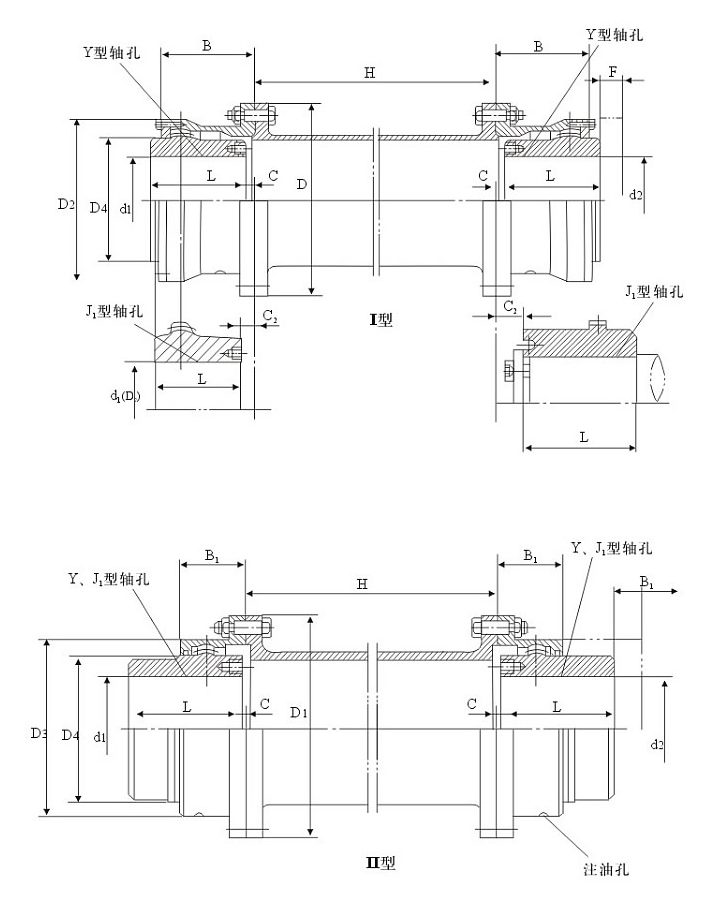

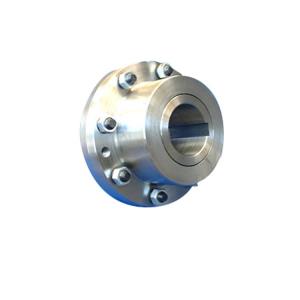

Type I-The sealing end cover is a separate type, with a large tooth spacing, which can allow a large radial displacement, and can be connected with Y, J1, and Z1 shaft extensions;

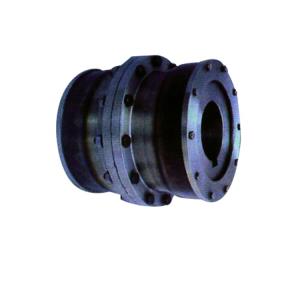

Type II-The sealing end cover is an integral type, with small tooth spacing, relatively small radial displacement, compact structure, small moment of inertia, and can be connected with Y and J1 shaft extensions;

Basic parameters and main dimensions of WGT sleeve cylindrical gear coupling: (JB/T 7004-93) mm

Email:

Email: