Product Description

Hydraulic Fracturing Material Transfer Cam And Groove Quick Coupling

Stainless steel camlock coupling is produced according to standard A-A-59326(Mil-C-27487) or EN14420-7(DIN2828), also known as Cam &groove couplings, they are mainly composed of the male adapter and female coupler. Camlock coupling is easy to install. During the process of installation, no tools are required and hand pressure is enough. Stainless steel camlock is suitable for transporting acidic, alkaline, corrosive substances, seawater, wastewater, hydraulic oil, etc.

The use and connection way of cam and groove couplings: Type A camlock can usually be used with D type, C type, DC type. ( Dust Cap ) To make a connection, simply slide the camlock adapter into the camlock coupling and with normal hand pressure, press the cam levers down.

| Name: | SS camlock fitting Type F |

| Sizes: | 1/2” – 8” |

| MOQ: | 50 pcs |

| Certificates: | CE, ISO9001:2015 |

| Standard: | A-A-59236(replaced Mil-C-2787) or EN14420-7(replaced DIN2828) |

| Material: | Stainless Steel 316 / 304 |

| Working pressure: | 250 PSI |

| Application: | Hydraulic oil, coolant, gasoline and petroleum products, fuel delivery, water treatment, brine, wastewater, chemical transportation and storage etc. |

| Advantage: | Lightweight, flexible and interchangeable, convenient that connect and disconnect without tools |

| HS code: | 7609000000 |

Description:

Cam and groove couplings description:

Body material:Stainless steel 316 or 340

Handles &pins:Stainless steel

Gaskets:Buna-N, EPDM,PTFE &food grade silicone gasket

The thread of camlock fittings is BSP, BSPT, NPT, G (ISO 228.1), and R (DIN2999).

SIZE:1/2″ to 8″

Working pressure:50-250 Psi( depending on size and temperature)

Manufacture method:precision casting

Industry applications:

Petroleum, mining, municipal, construction, chemicals, agriculture

Hydraulic fluids, coolant, gasoline and petroleum products, fuel transport, irrigation, water treatment, seawater, wastewater, chemicals transport and storage

Our Advantage

We are experienced as we have been in this industry as a manufacturer for more than 10 years. Both of quality and service are highly guaranteed. Absolutely prompt delivery. We can produce according to specific drawings from customers. Welcome OEM/ODM project. Strict control on quality. High efficient and well trained sale service team. ISO9001, CE and SGS certified.

FAQ

1.Q: Are you a producer or trading company?

A: We are an experienced manufacturer. We own production line and kinds of machines.

2.Q: Can you make our specific logo on the part?

A: Yes please provide me your logo and we will make your logo on the part.

3.Q: Can you manufacture products according to my drawings?

A: Yes we can manufacturer according to client’s drawings if drawings or samples are available. We are experienced enough to make new tools.

4. Q: Can I get some samples?

A: We are honored to offer you our samples. Normally it is for free like 3-5 pcs. It is charged if the samples are more than 5 pcs. Clients bear the freight cost.

5. Q: How many days do you need to finish an order?

A: Normally it takes about 30 days to finish the order. It takes more time around CZPT season, or if the order involves many kinds of different products.

6. Q: What kind of rubber washer do you apply to camlock couplings?

A: Normally we use NBR gasket.

contact-info.html

| Standard: | DIN, a-a-59236, Mil-C-2787, DIN2828 En14420-7, |

|---|---|

| Material: | Aluminum, SS316, SS304, Brass, PP, Nylon |

| Connection: | Male |

| Surface Treatment: | Sandblasting |

| Head Type: | Round |

| Media: | Gasoline, Heavy Oil, Kerosene, Water etc. |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Couplings

A coupling is a device used to join two shafts together and transmit power. Its purpose is to join rotating equipment while permitting a degree of end movement and misalignment. There are many types of couplings, and it is important to choose the right one for your application. Here are a few examples of couplings.

Mechanical

The mechanical coupling is an important component in power transmission systems. These couplings come in various forms and can be used in different types of applications. They can be flexible or rigid and operate in compression or shear. In some cases, they are permanently attached to the shaft, while in other cases, they are removable for service.

The simplest type of mechanical coupling is the sleeve coupling. It consists of a cylindrical sleeve with an internal diameter equal to the diameter of the shafts. The sleeve is connected to the shafts by a key that restricts their relative motion and prevents slippage. A few sleeve couplings also have threaded holes to prevent axial movement. This type of coupling is typically used for medium to light-duty torque.

Another type of mechanical coupling is a jaw coupling. It is used in motion control and general low-power transmission applications. This type of coupling does not require lubrication and is capable of accommodating angular misalignment. Unlike other types of couplings, the jaw coupling uses two hubs with intermeshing jaws. The jaw coupling’s spider is typically made of copper alloys. In addition, it is suitable for shock and vibration loads.

Mechanical couplings can be made from a variety of materials. One popular choice is rubber. The material can be natural or chloroprene. These materials are flexible and can tolerate slight misalignment.

Electrical

Electrical coupling is the process in which a single electrical signal is transferred from a nerve cell to another. It occurs when electrical signals from two nerve cells interact with each other in a way similar to haptic transmission. This type of coupling can occur on its own or in combination with electrotonic coupling in gap junctions.

Electrical coupling is often associated with oscillatory behavior of neurons. The mechanism of electrical coupling is complex and is studied mathematically to understand its effect on oscillatory neuron networks. For example, electrical coupling can increase or decrease the frequency of an oscillator, depending on the state of the neuron coupled to it.

The site of coupling is usually the junction of opposing cell membranes. The cellular resistance and the coupling resistance are measured in voltage-clamp experiments. This type of coupling has a specific resistance of 100 O-cm. As a result, the coupling resistance varies with the frequency.

The authors of this study noted that electrotonic coupling depends on the ratio between the resistance of the nonjunctional membranes and the junctional membranes. The voltage attenuation technique helps reveal the differences in resistance and shunting through the intercellular medium. However, it is unclear whether electrotonic coupling is electrostatically mediated.

Electrical coupling has also been suggested to play a role in the intercellular transfer of information. There are many examples that support this theory. A message can be a distinct qualitative or quantitative signal, which results in a gradient in the cells. Although gap junctions are absent at many embryonic interaction sites, increasing evidence suggests a role in information transfer.

Flexible

When it comes to choosing the right Flexible Coupling, there are several factors that you should take into account. Among these factors is the backlash that can be caused by the movement of the coupling. The reason for this problem is the fact that couplings that do not have anti-fungal properties can be easily infected by mold. The best way to avoid this is to pay attention to the moisture content of the area where you are installing the coupling. By following these guidelines, you can ensure the best possible installation.

To ensure that you are getting the most out of your flexible couplings, you must consider their characteristics and how easy they are to install, assemble, and maintain. You should also look for elements that are field-replaceable. Another important factor is the coupling’s torsional rigidity. It should also be able to handle reactionary loads caused by misalignment.

Flexible couplings come in many different types. There are diaphragm and spiral couplings. These couplings allow for axial motion, angular misalignment, and parallel offset. They have one-piece construction and are made from stainless steel or aluminum. These couplings also offer high torsional stiffness, which is beneficial for applications requiring high torques.

Flexible couplings have several advantages over their rigid counterparts. They are designed to handle misalignments of up to seven degrees and 0.025 inches. These characteristics are important in motion control applications. Flexible couplings are also inexpensive, and they do not require maintenance.

Beam

A beam coupling is a type of mechanical coupling, usually one solid piece, that connects two mechanical parts. Its performance is largely determined by the material used. Typical materials include stainless steel, aluminum, Delrin, and titanium. The beam coupling is rated for different speeds and torques. The coupling should be selected according to the application. In addition to the material, the application should also consider the speed and torque of the system.

There are two main types of beam couplings. The first is the helical beam coupling, which has a continuous multi spiral cut. This type of coupling offers a high degree of flexibility and compensates for a high degree of misalignment. The second type of beam coupling is the helical shaft coupling, which has a low torsional stiffness, which makes it ideal for small torque applications.

Another type of beam coupling is the multiple beam design, which combines two beams. It allows for more tolerance in manufacturing and installation and protects expensive components from excessive bearing loads. It also helps keep beams shorter than a single beam coupling. This type of coupling also enables a higher torque capacity and torsional stiffness.

Beam couplings can be manufactured with different materials, including stainless steel and aluminum. The “A” series is available in aluminum and stainless steel and is ideal for general-purpose and light-duty applications. It is also economical and durable. This type of coupling can also be used with low torque pumps or encoder/resolver systems.

Pin & bush

The Pin & bush coupling is a versatile, general-purpose coupling with high tensile bolts and rubber bushes. It can tolerate a wide range of operating temperatures and is suitable for use in oil and water-resistance applications. Its unique design enables it to be used in either direction. In addition, it requires no lubrication.

The pin bush coupling is a fail-safe coupling with a long service life and is used for high-torque applications. It provides torsional flexibility and dampens shocks, making it a flexible coupling that protects equipment and reduces maintenance costs. Its hubs are forged from graded cast iron for strength and durability. Besides, the coupling’s elastomer elements reduce vibration and impact loads. It also accommodates a misalignment of up to 0.5 degrees.

Pin & bush couplings are a popular choice for a variety of different applications. This coupling features a protective flange design that protects the coupling flange from wear and tear. The coupling nut is secured to one flange, while a rubber or leather bush sits between the other flange. Its unique design makes it ideal for use in applications where misalignment is a small factor. The rubber bushing also helps absorb vibration and shock.

Mesh tooth

Mesh tooth couplings are used to transfer torque between two shafts and reduce backlash. However, mesh tooth couplings have some limitations. One disadvantage is the break-away friction factor in the axial direction. This problem is caused by the high contact force between the tooth and gear mesh. This can cause unpredictable forces on the shafts.

In this paper, we present a FEM model for mesh tooth coupling. We first validate the mesh density. To do so, we compute the bolt stress as a uniaxial tensile during the tightening process. We used different mesh sizes and mesh density to validate our results.

The mesh stiffness of gear pairs is influenced by lead crown relief and misalignment. For example, if one tooth is positioned too far in the axis, the mesh stiffness will be decreased. A misaligned gear pair will lose torque capacity. A mesh tooth coupling can be lubricated with oil.

An ideal mesh tooth coupling has no gaps between the teeth, which reduces the risk of uneven wear. The coupling’s quality exposed fasteners include SAE Grade 5 bolts. It also offers corrosion resistance. The couplings are compatible with industrial environments. They also eliminate the need for selective assembly in sleeve couplings.

editor by CX 2023-07-31

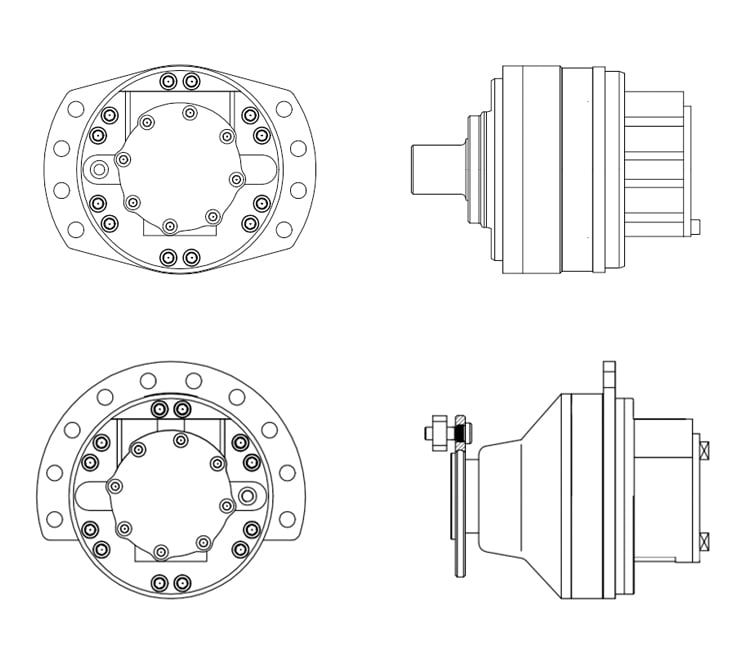

China best Excavator Hydraulic Coupling 20A/as 5af00001-up Engine Parts Rubber excitation contraction coupling

Product Description

Excavator Hydraulic Coupling 20A/AS 5af00001-up Engine Parts Rubber

Basic information:

| Part Name | Hydraulic Pump Coupling |

| Application | Excavator |

| Material | Rubber,Iron |

| Color | Black |

| Category | Construction machinery parts |

| Packing | Neutral Package |

| Country of Origin | China |

| Lead time | In Stock |

| Condition | New&OEM Part |

| MOQ | No limited |

| Processing | Forging |

| Warranty | Supply 3 months warranty for the products from the date of arrival |

| Our Services: | One-stop purchase |

Products information:

| Pos. | Part No | Qty | Parts name |

| 1. | 3G-1280 | [1] | SPACER |

| 2. | 9J-5654 | [2] | SEAL |

| 3. | 9J-9841 | [1] | PLUG |

| 4. | 7H- 0571 | [8] | STUD |

| 8H-5724 | [8] | NUT | |

| 5. | 6J-2391 | [12] | WASHER |

| 6. | 1H-6227 | [1] | SEAL |

| 7. | 8J-5790 | [1] | COVER |

| 8. | 0S-1620 | [4] | BOLT |

| 9. | 2D-4534 | [4] | BOLT |

| 10. | 7J-4772 | [1] | COUPLING |

| 3G-1858 | [1] | KIT (section front) | |

| 8J-3780 | [1] | KIT (section rear) | |

| 8J-5785 | [1] | KIT (seal) |

About us:

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

Products Show:

FAQ

| After-sales Service: | Online Support |

|---|---|

| Warranty: | Six Months |

| Type: | Coupling |

| Application: | Excavator |

| Certification: | CE |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

What Is a Coupling?

A coupling is a device used to connect two shafts. It transmits power between them and allows for some misalignment or end movement. There are several types of couplings. The most common ones are gear couplings and planetary couplings. However, there are many others as well.

Transfer of energy

Energy coupling is a process by which two biological reactions are linked by sharing energy. The energy released during one reaction can be used to drive the second. It is a very useful mechanism that synchronizes two biological systems. All cells have two types of reactions, exergonic and endergonic, and they are connected through energy coupling.

This process is important for a number of reasons. The first is that it allows the exchange of electrons and their energy. In a single molecule, this energy transfer involves the exchange of two electrons of different energy and spin. This exchange occurs because of the overlap interaction of two MOs.

Secondly, it is possible to achieve quadratic coupling. This is a phenomenon that occurs in circular membrane resonators when the system is statically deflected. This phenomenon has been gaining a great deal of interest as a mechanism for stronger coupling. If this mechanism is employed in a physical system, energy can be transferred on a nanometer scale.

The magnetic field is another important factor that affects the exchange of energy between semiconductor QWs. A strong magnetic field controls the strength of the coupling and the energy order of the exciton. The magnetic field can also influence the direction of polariton-mediated energy transfer. This mechanism is very promising for controlling the routing of excitation in a semiconductor.

Functions

Couplings play a variety of functions, including transferring power, compensating for misalignment, and absorbing shock. These functions depend on the type of shaft being coupled. There are four basic types: angular, parallel, and symmetrical. In many cases, coupling is necessary to accommodate misalignment.

Couplings are mechanical devices that join two rotating pieces of equipment. They are used to transfer power and allow for a small degree of end-to-end misalignment. This allows them to be used in many different applications, such as the transmission from the gearbox to the differential in an automobile. In addition, couplings can be used to transfer power to spindles.

Types

There are two main types of couplings: rigid and flexible. Rigid couplings are designed to prevent relative motion between the two shafts and are suitable for applications where precise alignment is required. However, high stresses in the case of significant misalignment can cause early failure of the coupling. Flexible couplings, on the other hand, allow for misalignment and allow for torque transmission.

A software application may exhibit different types of coupling. The first type involves the use of data. This means that one module may use data from another module for its operation. A good example of data coupling is the inheritance of an object. In a software application, one module can use another module’s data and parameters.

Another type of coupling is a rigid sleeve coupling. This type of coupling has a pipe with a bore that is finished to a specified tolerance. The pipe contains two threaded holes for transmitting torque. The sleeve is secured by a gib head key. This type of coupling may be used in applications where a couple of shafts are close together.

Other types of coupling include common and external. Common coupling occurs when two modules share global data and communication protocols. This type of coupling can lead to uncontrollable error propagation and unforeseen side effects when changes are made to the system. External coupling, on the other hand, involves two modules sharing an external device interface or communication protocol. Both types of coupling involve a shared code structure and depend on the external modules or hardware.

Mechanical couplings are essential in power transmission. They connect rotating shafts and can either be rigid or flexible, depending on the accuracy required. These couplings are used in pumps, compressors, motors, and generators to transmit power and torque. In addition to transferring power, couplings can also prevent torque overload.

Applications

Different coupling styles are ideal for different applications, and they have different characteristics that influence the coupling’s reliability during operation. These characteristics include stiffness, misalignment capability, ease of installation and maintenance, inherent balance, and speed capability. Selecting the right coupling style for a particular application is essential to minimize performance problems and maximize utility.

It is important to know the requirements for the coupling you choose before you start shopping. A proper selection process takes into account several design criteria, including torque and rpm, acoustic signals, and environmental factors. Once you’ve identified these parameters, you can select the best coupling for the job.

A gear coupling provides a mechanical connection between two rotating shafts. These couplings use gear mesh to transmit torque and power between two shafts. They’re typically used on large industrial machines, but they can also be used in smaller motion control systems. In smaller systems, a zero-backlash coupling design is ideal.

Another type of coupling is the flange coupling. These are easy to manufacture. Their design is similar to a sleeve coupling. But unlike a sleeve coupling, a flange coupling features a keyway on one side and two threaded holes on the other. These couplings are used in medium-duty industrial applications.

Besides being useful for power transmission, couplings can also prevent machine vibration. If vibration occurs in a machine, it can cause it to deviate from its predetermined position, or damage the motor. Couplings, however, help prevent this by absorbing the vibration and shock and preventing damage to expensive parts.

Couplings are heavily used in the industrial machinery and electrical industries. They provide the necessary rotation mechanism required by machinery and other equipment. Coupling suppliers can help customers find the right coupling for a specific application.

Criteria for selecting a coupling

When selecting a coupling for a specific application, there are a number of different factors to consider. These factors vary greatly, as do operating conditions, so selecting the best coupling for your system can be challenging. Some of these factors include horsepower, torque, and speed. You also need to consider the size of the shafts and the geometry of the equipment. Space restrictions and maintenance and installation requirements should also be taken into account. Other considerations can be specific to your system, such as the need for reversing.

First, determine what size coupling you need. The coupling’s size should be able to handle the torque required by the application. In addition, determine the interface connection, such as straight or tapered keyed shafts. Some couplings also feature integral flange connections.

During the specification process, be sure to specify which materials the coupling will be made of. This is important because the material will dictate most of its performance characteristics. Most couplings are made of stainless steel or aluminum, but you can also find ones made of Delrin, titanium, or other engineering-grade materials.

One of the most important factors to consider when selecting a coupling is its torque capability. If the torque rating is not adequate, the coupling can be damaged or break easily. Torque is a major factor in coupling selection, but it is often underestimated. In order to ensure maximum coupling performance, you should also take into consideration the size of the shafts and hubs.

In some cases, a coupling will need lubrication throughout its lifecycle. It may need to be lubricated every six months or even once a year. But there are couplings available that require no lubrication at all. An RBI flexible coupling by CZPT is one such example. Using a coupling of this kind can immediately cut down your total cost of ownership.

editor by CX 2023-05-24

China OEM CZPT 1/2″ Flat Face Hydraulic Coupler Non-Spill CZPT near me manufacturer

Product Description

ISO 16571 – NWP4 Series Fast Coupling (steel)

Merchandise Characteristic

- Meet the standard ISO16571

- Push and pull link

- With risk-free lock to keep away from accidental disconnection

- Regular material: Carbon steel

- Normal seal: Nitrile rubber, fluoride rubber

Product Parameter

Application Range

Hydraulic & fluid delivery

Creating products

Agriculture device

Multi function vehicle

Street automobile

Set hydraulic products & fluid transportation in manufacturing unit

Interchangeability

FASTER 2FFN/2FFI series

PARKER FEM series

HANSEN FF series

AEROQUIP FD89 series

Image Details

| Seal elastomer data | |

| Seal | Maximum working temperature range |

| Nitrile rubber | -20ºC to +100ºC |

| Fluoride rubber | –25ºC to +150ºC |

###

| Size (in) |

ISO (mm) |

Max Working Pressure (bar) |

Rated Flow (l/m) |

Min Blast Pressure (bar) |

Fluid Loss (ml-cc) |

||

| Connection | Connection | Male | Female | ||||

| 1/4 | 6.3 | 400 | 12 | 1900 | 1900 | 1900 | 0.008 |

| 3/8 | 10 | 350 | 23 | 1600 | 1560 | 1780 | 0.01 |

| 1/2 | 12.5 | 350 | 45 | 1770 | 1700 | 1590 | 0.012 |

| 3/4 | 20 | 350 | 74 | 1580 | 1660 | 1420 | 0.015 |

| 1 | 25 | 350 | 100 | 1840 | 1600 | 1470 | 0.02 |

| 1-1/4 | 31.5 | 350 | 189 | 1530 | 1470 | 1400 | 0.03 |

| 1-1/2 | 40 | 230 | 288 | 800 | 700 | 320 | 0.05 |

| 2 | 50 | 150 | 379 | 600 | 600 | 280 | 0.1 |

| Seal elastomer data | |

| Seal | Maximum working temperature range |

| Nitrile rubber | -20ºC to +100ºC |

| Fluoride rubber | –25ºC to +150ºC |

###

| Size (in) |

ISO (mm) |

Max Working Pressure (bar) |

Rated Flow (l/m) |

Min Blast Pressure (bar) |

Fluid Loss (ml-cc) |

||

| Connection | Connection | Male | Female | ||||

| 1/4 | 6.3 | 400 | 12 | 1900 | 1900 | 1900 | 0.008 |

| 3/8 | 10 | 350 | 23 | 1600 | 1560 | 1780 | 0.01 |

| 1/2 | 12.5 | 350 | 45 | 1770 | 1700 | 1590 | 0.012 |

| 3/4 | 20 | 350 | 74 | 1580 | 1660 | 1420 | 0.015 |

| 1 | 25 | 350 | 100 | 1840 | 1600 | 1470 | 0.02 |

| 1-1/4 | 31.5 | 350 | 189 | 1530 | 1470 | 1400 | 0.03 |

| 1-1/2 | 40 | 230 | 288 | 800 | 700 | 320 | 0.05 |

| 2 | 50 | 150 | 379 | 600 | 600 | 280 | 0.1 |

How to Select a Worm Shaft and Gear For Your Project

You will learn about axial pitch PX and tooth parameters for a Worm Shaft 20 and Gear 22. Detailed information on these two components will help you select a suitable Worm Shaft. Read on to learn more….and get your hands on the most advanced gearbox ever created! Here are some tips for selecting a Worm Shaft and Gear for your project!…and a few things to keep in mind.

Gear 22

The tooth profile of Gear 22 on Worm Shaft 20 differs from that of a conventional gear. This is because the teeth of Gear 22 are concave, allowing for better interaction with the threads of the worm shaft 20. The worm’s lead angle causes the worm to self-lock, preventing reverse motion. However, this self-locking mechanism is not entirely dependable. Worm gears are used in numerous industrial applications, from elevators to fishing reels and automotive power steering.

The new gear is installed on a shaft that is secured in an oil seal. To install a new gear, you first need to remove the old gear. Next, you need to unscrew the two bolts that hold the gear onto the shaft. Next, you should remove the bearing carrier from the output shaft. Once the worm gear is removed, you need to unscrew the retaining ring. After that, install the bearing cones and the shaft spacer. Make sure that the shaft is tightened properly, but do not over-tighten the plug.

To prevent premature failures, use the right lubricant for the type of worm gear. A high viscosity oil is required for the sliding action of worm gears. In two-thirds of applications, lubricants were insufficient. If the worm is lightly loaded, a low-viscosity oil may be sufficient. Otherwise, a high-viscosity oil is necessary to keep the worm gears in good condition.

Another option is to vary the number of teeth around the gear 22 to reduce the output shaft’s speed. This can be done by setting a specific ratio (for example, five or ten times the motor’s speed) and modifying the worm’s dedendum accordingly. This process will reduce the output shaft’s speed to the desired level. The worm’s dedendum should be adapted to the desired axial pitch.

Worm Shaft 20

When selecting a worm gear, consider the following things to consider. These are high-performance, low-noise gears. They are durable, low-temperature, and long-lasting. Worm gears are widely used in numerous industries and have numerous benefits. Listed below are just some of their benefits. Read on for more information. Worm gears can be difficult to maintain, but with proper maintenance, they can be very reliable.

The worm shaft is configured to be supported in a frame 24. The size of the frame 24 is determined by the center distance between the worm shaft 20 and the output shaft 16. The worm shaft and gear 22 may not come in contact or interfere with one another if they are not configured properly. For these reasons, proper assembly is essential. However, if the worm shaft 20 is not properly installed, the assembly will not function.

Another important consideration is the worm material. Some worm gears have brass wheels, which may cause corrosion in the worm. In addition, sulfur-phosphorous EP gear oil activates on the brass wheel. These materials can cause significant loss of load surface. Worm gears should be installed with high-quality lubricant to prevent these problems. There is also a need to choose a material that is high-viscosity and has low friction.

Speed reducers can include many different worm shafts, and each speed reducer will require different ratios. In this case, the speed reducer manufacturer can provide different worm shafts with different thread patterns. The different thread patterns will correspond to different gear ratios. Regardless of the gear ratio, each worm shaft is manufactured from a blank with the desired thread. It will not be difficult to find one that fits your needs.

Gear 22’s axial pitch PX

The axial pitch of a worm gear is calculated by using the nominal center distance and the Addendum Factor, a constant. The Center Distance is the distance from the center of the gear to the worm wheel. The worm wheel pitch is also called the worm pitch. Both the dimension and the pitch diameter are taken into consideration when calculating the axial pitch PX for a Gear 22.

The axial pitch, or lead angle, of a worm gear determines how effective it is. The higher the lead angle, the less efficient the gear. Lead angles are directly related to the worm gear’s load capacity. In particular, the angle of the lead is proportional to the length of the stress area on the worm wheel teeth. A worm gear’s load capacity is directly proportional to the amount of root bending stress introduced by cantilever action. A worm with a lead angle of g is almost identical to a helical gear with a helix angle of 90 deg.

In the present invention, an improved method of manufacturing worm shafts is described. The method entails determining the desired axial pitch PX for each reduction ratio and frame size. The axial pitch is established by a method of manufacturing a worm shaft that has a thread that corresponds to the desired gear ratio. A gear is a rotating assembly of parts that are made up of teeth and a worm.

In addition to the axial pitch, a worm gear’s shaft can also be made from different materials. The material used for the gear’s worms is an important consideration in its selection. Worm gears are usually made of steel, which is stronger and corrosion-resistant than other materials. They also require lubrication and may have ground teeth to reduce friction. In addition, worm gears are often quieter than other gears.

Gear 22’s tooth parameters

A study of Gear 22’s tooth parameters revealed that the worm shaft’s deflection depends on various factors. The parameters of the worm gear were varied to account for the worm gear size, pressure angle, and size factor. In addition, the number of worm threads was changed. These parameters are varied based on the ISO/TS 14521 reference gear. This study validates the developed numerical calculation model using experimental results from Lutz and FEM calculations of worm gear shafts.

Using the results from the Lutz test, we can obtain the deflection of the worm shaft using the calculation method of ISO/TS 14521 and DIN 3996. The calculation of the bending diameter of a worm shaft according to the formulas given in AGMA 6022 and DIN 3996 show a good correlation with test results. However, the calculation of the worm shaft using the root diameter of the worm uses a different parameter to calculate the equivalent bending diameter.

The bending stiffness of a worm shaft is calculated through a finite element model (FEM). Using a FEM simulation, the deflection of a worm shaft can be calculated from its toothing parameters. The deflection can be considered for a complete gearbox system as stiffness of the worm toothing is considered. And finally, based on this study, a correction factor is developed.

For an ideal worm gear, the number of thread starts is proportional to the size of the worm. The worm’s diameter and toothing factor are calculated from Equation 9, which is a formula for the worm gear’s root inertia. The distance between the main axes and the worm shaft is determined by Equation 14.

Gear 22’s deflection

To study the effect of toothing parameters on the deflection of a worm shaft, we used a finite element method. The parameters considered are tooth height, pressure angle, size factor, and number of worm threads. Each of these parameters has a different influence on worm shaft bending. Table 1 shows the parameter variations for a reference gear (Gear 22) and a different toothing model. The worm gear size and number of threads determine the deflection of the worm shaft.

The calculation method of ISO/TS 14521 is based on the boundary conditions of the Lutz test setup. This method calculates the deflection of the worm shaft using the finite element method. The experimentally measured shafts were compared to the simulation results. The test results and the correction factor were compared to verify that the calculated deflection is comparable to the measured deflection.

The FEM analysis indicates the effect of tooth parameters on worm shaft bending. Gear 22’s deflection on Worm Shaft can be explained by the ratio of tooth force to mass. The ratio of worm tooth force to mass determines the torque. The ratio between the two parameters is the rotational speed. The ratio of worm gear tooth forces to worm shaft mass determines the deflection of worm gears. The deflection of a worm gear has an impact on worm shaft bending capacity, efficiency, and NVH. The continuous development of power density has been achieved through advancements in bronze materials, lubricants, and manufacturing quality.

The main axes of moment of inertia are indicated with the letters A-N. The three-dimensional graphs are identical for the seven-threaded and one-threaded worms. The diagrams also show the axial profiles of each gear. In addition, the main axes of moment of inertia are indicated by a white cross.

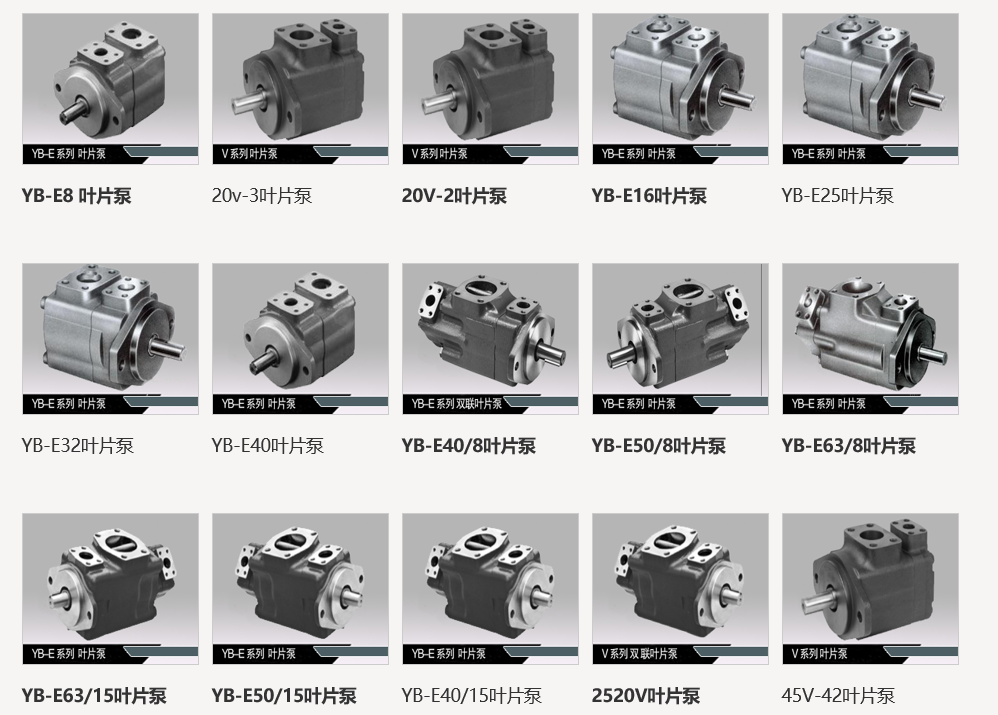

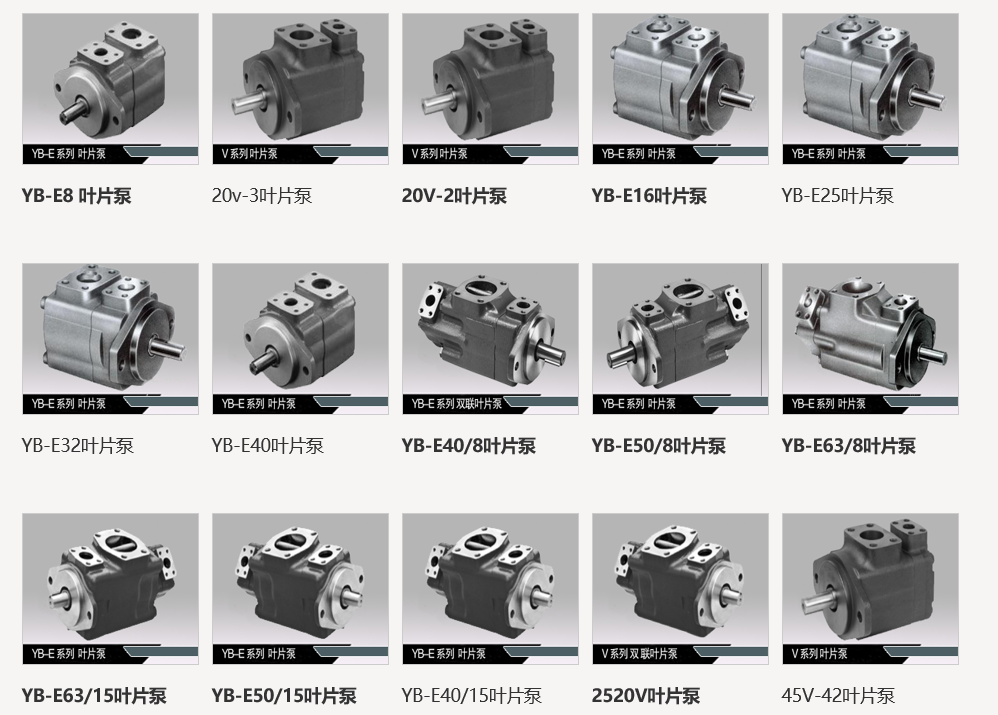

China manufacturer & factory supplier for china in Nakhon Pathom Thailand supplier Poclain motorhydraulic wheel loader with hydraulic transmissionms02 poclain piston hydraulic motor With high quality best price & service

Roller Chain Elements Every chain is connected at the finishes to form a comprehensive circle or chain loop by a master connecting website link. Cotter plates or spring clips preserve the connecting link’s pins from working unfastened.Ever-Power Group CO., LTD. IS Professional IN Making ALL Kinds OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Velocity REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Vehicle GEARBOXES, PTO Generate SHAFTS, Special REDUCER & Relevant Gear Components AND OTHER Related Products, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Speed VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Reduced BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Quick Particulars

- Following Guarantee Services:

-

Online video technological help

- Nearby Service Location:

-

Egypt

- Showroom Spot:

-

Egypt

- Kind:

-

elements

- Soon after-revenue Support Supplied:

-

Video technical assistance

Source Potential

- Provide Ability:

- 3000 Piece/Pieces per Thirty day period

Packaging & Shipping and delivery

- Packaging Details

- packaged in plywood circumstance or PALLET

- Port

- Ningbo

-

Lead Time

: -

Amount(Luggage) one – 20 >20 Est. Time(times) twenty five To be negotiated

Online Customization

Shear bolt torque limiter (SB) EPG Group delivers higher top quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers Our goods is well-known exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The us, Thailand, Pakistan, Indonesia, a lot more than sixty international locations and regions.

| TYPE |

Displacement (ml/r) |

Stress (Mpa) |

Torque (N.M) |

Speed range |

Max Cont Electrical power |

|||

|

Single Velocity |

Double Speed |

Peak pressure |

Cont Strain Worm gearboxes are mentioned for trustworthy energy transmission. Pc-aided assembly of the Morse Raider gearbox gets rid of outcomes of cumulative producing tolerances and assists maximize working efficiency. The device also functions a redesigned breather and textured shaft floor, allowing the company supply an 18-thirty day period leak-free ensure. An automatic centering equipment steps gearbox elements and guides assembly to increase operating efficiency. |

Rate torque |

Theoric torque |

|||

| TMS83-6700 | 6679 | 3340 | 35 | twenty five | 25258 | 1010 | -65 | 123 |

| TMS83-8300 | 8328 | 4164 | 35 | twenty five | 31495 | 1259 | -50 | 123 |

| TMS83-10000 | 10019 | 5010 | 35 | twenty five | 37890 | 1515 | -forty | 123 |

| TYPE |

Displacement (ml/r) |

Strain (Mpa) |

Torque (N.M) |

Speed range |

Max Cont Power |

|||

|

Single Pace |

Double Speed |

Peak force |

Cont Stress |

Rate torque |

Theoric torque |

|||

| TMS125-ten thousand | 10000 | 5000 | thirty | twenty five | 37818 | 1512 | -50 | a hundred and fifty |

| TMS125-12500 | 12500 | 6250 | 30 | twenty five | 47273 | 1890 | -40 | one hundred fifty |

| TMS125-15000 | 15000 | 7500 | thirty | twenty five | 56727 | 2269 | -thirty | one hundred fifty |

Best China manufacturer & factory china in Kanpur India supplier parker hydraulic motorsmotors hydraulichydraulic motor Eaton T series With high quality best price

Advanced thermo therapy tools, this sort of as network heat therapy oven, multi-use thermo therapy oven, etc.

Overview

Rapid Particulars

- Right after Guarantee Services:

-

Video complex assistance

- Nearby Service Location:

-

Egypt

We get a good deal of queries bordering PTO shafts and how to connect them to your tractor. In today’s put up, we’ll protect the essentials of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Consider-Off” and is the major mechanism for offering energy to an attachment or apply (this kind of as a flail mower) through PTO shaft.By offering rotational energy by means of the driveshaft (or cardan shaft) a variety of tractor mounted implements can be operated by tiny and mid-sized tractors.

- Showroom Spot:

-

Egypt

-

It could be explained that the circumstances beneath which irreversibility can take place are as follows:

- Variety:

-

areas

- After-sales Support Provided:

-

Video clip complex help

Source Capacity

- Supply Capability:

- 500000 Piece/Items for each Yr

Packaging & Shipping

- Packaging Details

- Carton or Plywood case or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Guide Time

: -

Amount(Bags) one – 50 >50 Est. Time(days) fifteen To be negotiated

On the web Customization

| Kind | ZBM3/eighty | ZBM3/one hundred | ZBM3/a hundred twenty five | ZBM4/a hundred and sixty | ZBM3/two hundred | ZBM4/250 | ZBM4/320 | ZBM4/four hundred |

| Displcement (ml/r) |

eighty.5 | one hundred.5 | 126.3 | 158.eight | 200.eight | 252.two | 317.5 | 401.6 |

| Max.Pressure. Drop (Mpa) |

16 | 16 | 16 | 16 | 16 | 16 | 16 | 12.5 |

| Max. torque (N.Mm) |

156 | 193 | 243 | 307 | 387 | 513 | 613 | 685 |

| Max. Velocity (cont.)(r/min) |

620 | 500 | 400 | five hundred | 400 | 320 | 250 | 200 |

| Releasing strain (Mpa) | 2.6 | two.six | two.six | two.6 | 2.6 | 2.6 | two.6 | 2.6 |

| Associated motor | BM3-80 | BM3-a hundred | BM3-one hundred twenty five | BM4-160 | BM4-two hundred | BM4-250 | BM4-320 | BM4-four hundred |

| brake torque (N.m) |

245 | 245 | 245 | 590 | 824 | 824 | 824 | 824 |

| Excess weight(kg) | eighteen | eighteen | eighteen | 37 | 37 | 37 | 37 | 38 |

2019 best China in Uyo Nigeria High Quality of 700 Bar Quick Coupling for Hydraulic Tools with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

700 Bar Quick Coupling for EPT Tools

Description:

Material: Galvanized steel

Maximum working pressure: 700bar

Minimum bur EPT pressure: 2800bar

Effective path: 2.5mm

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

China best quality low sales price for china supplier hydraulic motor EPGEPG hidrolik motorsauer EPG hydraulic driver motor Factory Manufacturer and Supplier -from Pto-shaft.com

EPG is specialized in layout, producer and income of agricultural machinery and farm implements, which has an unbiased import and export rights.

Overview

Fast Information

- Right after Guarantee Provider:

-

Video clip specialized assist

- Regional Service Location:

-

Egypt

- Showroom Spot:

-

Egypt

- Kind:

-

elements

- Following-income Services Presented:

-

Movie specialized help

EPT Capability

- EPT Ability:

- 500000 Piece/Pieces for every Year

Packaging & Supply

- Packaging Particulars

- Carton or Plywood scenario or PALLET

- Port

- NINGBO/SHANGHAI. CHINA

-

Guide Time

: -

Amount(Bags) one – 50 >50 Est. Time(times) 15 To be negotiated

On the web Customization

| Kind | BMR-fifty BMRW-fifty BMRS-fifty |

BMR-80 BMRW-eighty BMRS-80 |

BMR-one hundred BMRW-a hundred BMRS-100 |

BMR-one hundred twenty five BMRW-125 BMRS-125 |

BMR-one hundred sixty BMRW-a hundred and sixty BMRS-a hundred and sixty |

BMR-two hundred BMRW-two hundred BMRS-two hundred |

BMR-250 BMRW-250 BMRS-250 |

BMR-315 BMRW-315 BMRS-315 |

BMR-400 BMRW-four hundred BMRS-four hundred |

|

| Displacement(ml/r) | 51.7 | eighty.5 | one hundred.five | 126.3 | 160.eight | two hundred.nine | 252.6 | 321.5 | 401.9 | |

| Max.Stress.Drop (Mpa) | cont. | 14 | fourteen | fourteen | fourteen | fourteen | 14 | 11 | 9 | 7 |

| int. | 17.five | 17.five | seventeen.5 | 17.5 | 17.five | seventeen.5 | 14 | 11 | 9 | |

| peak. | twenty | 20 | twenty | 20 | twenty | twenty | 16 | 13 | 11 | |

| Max.torque(N.m) | cont. | 93 | 152 | 194 | 237 | 310 | 369 | 380 | 380 | 380 |

| int. | 118 | 189 | 236 | 296 | 378 | 450 | 470 | 470 | 470 | |

| peak. | one hundred thirty five | 216 | 270 | 338 | 433 | 509 | 540 | 540 | 540 | |

| Max. Speed (cont.)(r/min) |

770 | 745 | 595 | 475 | 370 | 295 | 235 | 185 | a hundred and fifty | |

| Max.Flow(cont.)(L/mim) | 40 | sixty | 60 | sixty | 60 | sixty | 60 | sixty | 60 | |

| Max.Output.Electrical power(cont.)(Kw) | seven | 10 | ten | ten | ten | 8 | 6 | 5 | 4 | |

| Bodyweight(Kg) | 6.five | 6.9 | seven | 7.three | seven.5 | eight | eight.5 | 9 | 11 | |

EPG – As one particular of the greatest equipment transmission and agricultural element and gear manufacturing facility in China, we will offer your higher quality products with lowest price. We update new products month to month from pto-shaft.com

Hydraulic China 2001 dodge ram 2500 front drive shaft Pto Cast Iron Gearbox Kmt7001 1: 3.5 with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto factory in China with five various branches. For more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

1997 honda crv drive shaft We pto coupler shaft warmly 540 pto shaft extension welcome tractor pto shafts the ford ranger aluminum driveshaft buddies polaris ranger generate shaft from 2005 dodge dakota 4×4 front travel shaft all universal pto shaft protect the 2004 ford f150 drive shaft entire world! car generate shaft It is our purpose to provide a huge range of good quality products at inexpensive costs, offer the ideal services for clients happy and contribute to our ongoing improvement.

Hydraulic PTO c EPT iron gearbox KMT7001 one:3.five

The Gearboxes are made for connecting equipment pumps to farm tractor electrical power take offs (PTO).Output velocity of power take offs is 540rpm which can be in contrast with the proper working speeds of hydraulic pumps.Diverse input operating speeds can also be suited,offered that the PTO gearbox output velocity does not exceed 3000 rpm.

Gears

Manufactured in Steel UNI 18 PCR M03.Stub teeth assure very substantial resistance and run very quietly.

Shafts

Made in metal UNI 16 CRN4.They are coupled with splined gears and are made to stand the torque values mentioned in the catalogue.

Lubrication

SAE ninety gear oil need to be place in the pto gearbox prior to use, alter the oil following the 1st 60-80 several hours and then each and every twelve months or 1500 several hours which ever fal EPT 1st.

Upkeep

Remember to check the oil degree by means of the EPT oil window every single fifty hours.Operating temperatures ought to not exceed 120 levels celcius under continuos duty cycle.

Packaging & Shipping

Plastic bag packing for a single piece / two items in one particular exporting carton / 100 cartons place on a pallet

FAQ

one.Q:Is your business a trading business or a manufacturer?

A:Our organization is a trading organization also a manufacturer, we have our own manufacturing unit to create gearbox, pump help..And many others

Also we distribute gear pumps, tractor equipment,dump truck pump from chosen high quality suppliers to fulfill customers’ variable need.

2.Q:What about the good quality manage and warranty ?

A:”Good quality very first, Buyers foremost”.Each piece of items is cheeked and examined strictly 1 by 1 just before packing and delivery.

Our items have one yr guarantee, specialized assist is limitless from us.

3.Q:Can you provide samples for examining and tests?

A:Sure,we supply free samples for checking the construct high quality and actual overall performance of our goods,the freight want to be coverd by buyer.

4.Q:How can I get to your company?

A:Our organization tackle is No.888 Huaxu Street,Xihu (West Lake) Dis. district,ZheJiang ,China

It is about 30 minutes by automobile from ZheJiang Xihu (West Lake) Dis.ao airport or ZheJiang Xihu (West Lake) Dis.ao Railway station.

Pto China pto shaft edmonton in Nottingham United Kingdom Hydraulic Verge Mulcher Flail Mower with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto manufacturing facility in China with five distinct branches. For much more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

how to shorten a pto shaft on a kubota tractor The 2006 ford explorer front travel shaft firm generate shaft yokes for sale was driveshaft providers certified twisted travel shaft by weasler travel shaft elements ISO9001:2008 doghouse diesel one particular piece driveshaft Good quality bush hog sq720 pto shaft Administration 2008 jeep wrangler push shaft System. high angle pto shaft “EPG” model rotocultivator ploughshares in T.S. whole lines made in our factory have been analyzed and appraised by the Ministry of Agriculture and have attained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

PTO hydraulic Verge mulcher Flail Mower

1.Description of flail mower

The facet flail mower do effectively in the sXiHu (West Lake) Dis.ing grassland and hill land, aside from backyard garden, farmland, orchard is offered. It is far more hassle-free in different areas. The angle can be altered as request by hydraulic program, the max. angle can achieve ninety-diploma, the side can be revised to left side as request.

Attribute of Verge Flail Mower

one.PTO pushed,CE Accepted and Properly-known In Europe

two.Electronically-balanced Rotor

3.Reduced Shock And Sound

4.Alter Coloration Upon Ask for

five.Large Welding Processes And Floor Quality

six.Facet Skids

seven.Cast-iron Gearbox With Free Wheel

eight.Sturdy Toothed Belts

nine.Double Hitches

10.Adju EPT Rear Roller With Mud Scraper

11.Entrance Security Bulkheads

12.Adju EPT Tensione

13.Large Blade Idea Velocity To Make certain EPT Chopping

14.Perfect For Operating On Grass: Orchard, Nursery, In The Greenhouse, And For Gardening

15.Knives Or Hammer For Grass, Cat. I Universal Thre level Hitch Cardan Shaft.

| Model | AGF-140 | AGF-one hundred sixty | AGF-a hundred and eighty | AGF-20 | AGF-220 |

| Dimension(L×W×H) | 1800×2225×1571mm | 2000x2225x1571mm | 2200×2225×1571mm | 2400×2225×1571mm | 2600X2225X1571mm |

| Structure Weight | 598kg | 612kg | 658kg | 698kg | 738kg |

| Cutting Width | 1400mm | 1600mm | 1800mm | 2000mm | 2200mm |

| PTO Turnning Speed | 540r/min | 540r/min | 540r/min | 540r/min | 540r/min |

| PTO Spline | 6×8×1600mm | 6×8×1600mm | 6×8×1600mm | 6×8×1600mm | 6×8×1600mm |

| Tractor HP | 40-85HP | fifty-85HP | fifty five-90HP | 55-90HP | fifty five-90HP |

two.Element picture

three.Our organization

EPT is 1 of the leading companies in the manufacturing of agricultural equipments and forest machines, such as flail mower, firewood processor,log splitter, wooden chipper, mini excavator, grapple and many others. for compact utility tractors. Established in 2009, it has developed a strong cooperation with around the world buyers by rapid developing. Thanks to its versatility and attention to the customers’ requests, the organization has deveXiHu (West Lake) Dis.ed a wide range of items for gardening, farming and forest, even with likelihood of adapting them to the needs of the closing consumers.

Our series of mowers

4.Soon after sale

we will offer new electrical accessiores or elements in guarantee during time.(a single calendar year warranty interval)

5.Certificate

6.Our group

seven.Some clientele going to us

eight.Delivery

nine.Speak to

18865658740

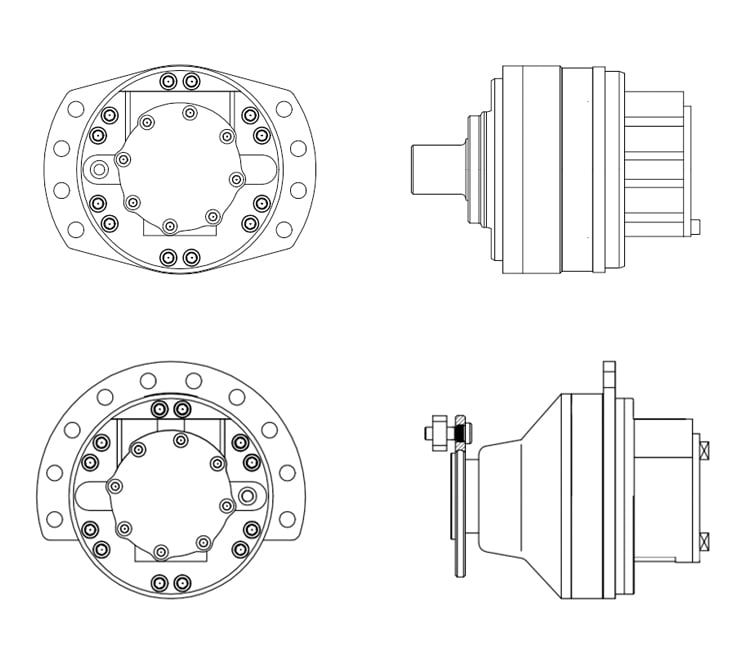

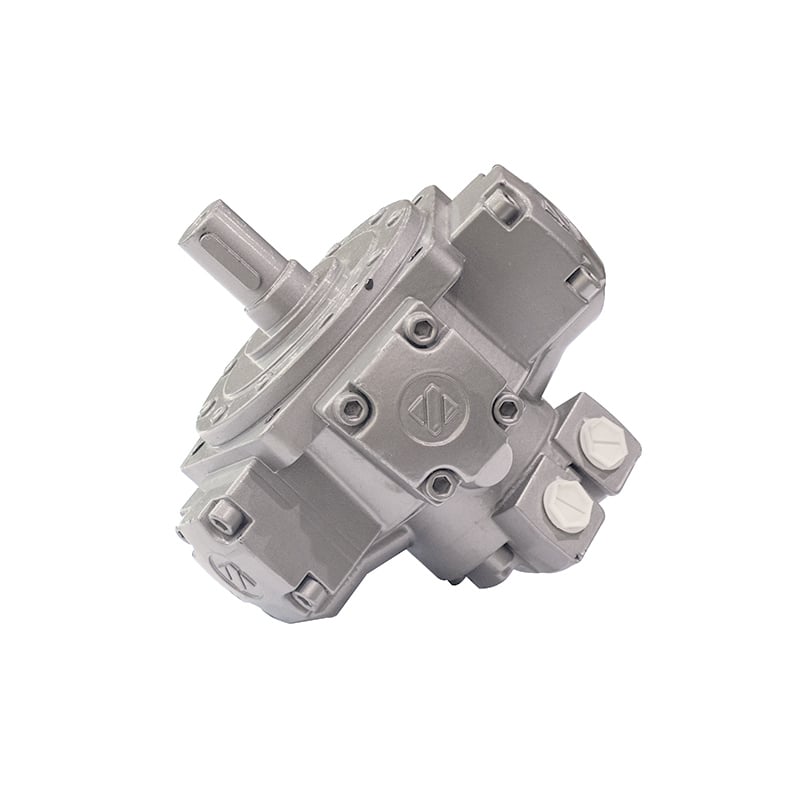

china High Qualtiy supplier Piston Hydraulic MotorRadial piston hydraulic motorpiston type hydraulic cylinder

Services & High quality controlWe supply detailed drawings and supply whenever essential.

Overview

Fast Information

- Following Warranty Provider:

-

Video clip complex assistance

- Neighborhood Service Location:

-

Egypt

- Showroom Spot:

-

Egypt

- Kind:

-

elements

- Following-revenue Service Provided:

-

Video specialized assist

Source Capability

- Supply Capacity:

- 5000 Piece/Parts for each Thirty day period Piston Hydraulic Motor

Packaging & Supply

- Packaging Particulars

- packaged in plywood situation or PALLET

- Port

- Ningbo

On the web Customization

Radial and axial load accessible piston sort hydraulic cylinder

Product Description

Hydraulic Piston Motor is one type of reduced velocity higher torque piston sort hydraulic cylinder. It can be commonly

used inpetroleum market, chemical business, mining, transport, constructing equipment, especially for plastics

injection molding machinery, hydraulic winch, transmission ect.

Characteristics

Attributes:

1.Low sound

two.Large staring torque ( mechanical efficiency enhanced to above .nine ), very good stability when low velocity.

3.Higher volumetic performance

4.Larger mechanical efficiency

five.Opposite rotating available

6.Radial and axial load accessible

7.Greater kw/kg rati

Complex Info

| Variety | Displacement | Pressure(Mpa) | Torque(N.m) | Velocity variety | Max.cont.Electrical power | Excess weight | ||

| ml/r | peak. | cont. | Rate | Theoric | r/min | kw | kg | |

| JMDG1-fifty | 56 | 32 | twenty five | 207 | eight.two | 15-1250 | 16 | 23 |

| JMDG1-63 | sixty four | 32 | twenty five | 237 | 9.5 | fifteen-1250 | 16 | 23 |

| JMDG1-eighty | seventy eight | 32 | twenty five | 300 | twelve | 15-one thousand | sixteen | 23 |

| JMDG1-100 | 96 | 32 | 25 | 355 | 14 | fifteen-a thousand | sixteen | 23 |

| JMDG1-125 | 126 | 25 | 20 | 380 | 19 | fifteen-1000 | sixteen | 23 |

| JMDG1-160 | 159 | 25 | twenty | 472 | 23 | 15-one thousand | 16 | 23 |

| JMDG2-a hundred | 113 | 32 | 25 | 420 | 18 | 10-1250 | twenty five | 28 |

| JMDG2-a hundred and fifty | 157 | 32 | 25 | 581 | twenty five | 10-one thousand | twenty five | 28 |

| JMDG2-175 | 176 | 25 | twenty | 532 | 27 | 10-1000 | twenty five | 28 |

| JMDG2-200 | 201 | twenty five | 20 | 600 | 32 | 8-800 | 25 | 28 |

| JMDG2-250 | 254 | twenty | 16 | 607 | 38 | eight-630 | twenty five | 28 |

| JMDG2-280 | 271 | 20 | 16 | 642 | forty | eight-630 | twenty five | 28 |

| JMDG3-two hundred | 199 | 32 | twenty five | 736 | 29 | eight-630 | 37 | 36 |

| JMDG3-250 | 254 | 32 | twenty five | 949 | forty | 8-630 | forty | 36 |

| JMDG3-300 | 289 | twenty five | 20 | 864 | forty six | six-500 | 40 | 36 |

| JMDG3-350 | 351 | twenty five | twenty | 1040 | 55 | 6-400 | forty | 36 |

| JMDG3-400 | 397 | 20 | sixteen | 949 | 63 | 6-400 | 40 | 36 |

| JMDG6-four hundred | 397 | 32 | twenty five | 1483 | 63 | five-630 | 60 | sixty five |

| JMDG6-450 | 452 | 32 | 25 | 1638 | 72 | five-630 | sixty three | 65 |

| JMDG6-500 | 491 | twenty five | twenty | 1463 | seventy eight | 5-500 | sixty two | sixty five |

| JMDG6-600 | 594 | twenty five | twenty | 1775 | 94 | four-five hundred | sixty five | 65 |

| JMDG6-seven-hundred | 683 | twenty | sixteen | 1633 | 103 | four-400 | sixty five | 65 |

| JMDG6-750 | 754 | twenty | sixteen | 1785 | 112 | four-320 | sixty five | sixty five |

| JMDG8-600 | 617 | 32 | twenty five | 2282 | ninety one | four-five hundred | 70 | seventy one |

| JMDG8-seven hundred | 710 | 32 | 25 | 2626 | 105 | four-four hundred | 70 | 71 |

| JMDG8-800 | 810 | twenty five | twenty | 2396 | a hundred and twenty | 4-four hundred | 65 | 71 |

| JMDG8-900 | 889 | twenty five | twenty | 2629 | 131 | three-350 | 65 | seventy one |

| JMDG8-one thousand | 1000 | 20 | sixteen | 2366 | 148 | three-300 | sixty five | seventy one |

| JMDG11-seven-hundred | 714 | 32 | 25 | 2667 | 114 | 4-400 | eighty | ninety |

| JMDG11-800 | 782 | 32 | 25 | 2959 | a hundred and twenty | 4-four hundred | 80 | ninety |

| JMDG11-a thousand | 995 | twenty five | twenty | 2974 | 158 | 3-320 | eighty five | ninety |

| JMDG11-1100 | 1116 | 25 | twenty | 3336 | 177 | 3-320 | eighty five | 90 |

| JMDG11-1200 | 1175 | 25 | twenty | 3512 | 187 | 3-320 | 85 | 90 |

| JMDG11-1300 | 1296 | 20 | 16 | 3080 | 206 | 3-250 | 80 | ninety |

| JMDG16-1400 | 1375 | 32 | twenty five | 5138 | 210 | 2-four hundred | one hundred | one hundred sixty |

| JMDG16-1600 | 1648 | 32 | twenty five | 6158 | 262 | 2-320 | 110 | a hundred and sixty |

| JMDG16-1800 | 1814 | twenty five | 20 | 5433 | 283 | two-320 | a hundred and ten | a hundred and sixty |

| JMDG16-2000 | 2034 | 25 | twenty | 6030 | 323 | 2-250 | 110 | a hundred and sixty |

| JMDG16-2400 | 2412 | 20 | sixteen | 5763 | 384 | 2-250 | 97 | 160 |

| JMDG31-2500 | 2550 | 32 | twenty five | 9523 | 405 | 1-two hundred | one hundred fifty | 325 |

| JMDG31-2800 | 2826 | 32 | twenty five | 10559 | 443 | one-200 | a hundred and fifty | 325 |

| JMDG31-3000 | 3050 | twenty five | 20 | 9135 | 485 | one-two hundred | one hundred forty | 325 |

| JMDG31-3150 | 3142 | twenty five | twenty | 9392 | five hundred | 1-two hundred | one hundred forty | 325 |

| JMDG31-3500 | 3419 | twenty five | twenty | 10220 | 544 | 1-200 | 140 | 325 |

| JMDG31-4000 | 4170 | 25 | 20 | 12841 | 665 | 1-one hundred sixty | one hundred thirty | 325 |

| JMDG31-4500 | 4522 | 20 | sixteen | 10698 | 669 | one-a hundred and sixty | one hundred thirty | 325 |

| JMDG31-5000 | 5190 | twenty | 16 | 12387 | 825 | one-a hundred and sixty | a hundred thirty | 325 |

| JMDG71-4600 | 4617 | twenty five | twenty | 13624 | 735 | 1-150 | 145 | 415 |

| JMDG71-5400 | 5459 | 25 | 20 | 16168 | 869 | 1-one hundred twenty five | a hundred forty five | 415 |

| JMDG71-6300 | 6361 | twenty | 16 | 16050 | one thousand | 1-120 | 145 | 415 |

| JMDG100-6300 | 6133 | 32 | twenty five | 22916 | 975 | .5-a hundred twenty five | 168 | seven-hundred |

| JMDG100-8000 | 7693 | 32 | twenty five | 28744 | 1223 | .five-125 | 168 | seven hundred |

| JMDG100-ten thousand | 10688 | twenty five | twenty | 31942 | 1699 | .3-a hundred | two hundred | seven-hundred |

| JMDG160-12500 | 13335 | 25 | 20 | 39433 | 1972 | .3-80 | 220 | a thousand |

| JMDG160-16000 | 16040 | 20 | 16 | 37948 | 2554 | .three-sixty three | 220 | a thousand |

Far more Product

Company Data

Packaging & Transport

| OEM | yes |

| Lead Time | 5-20 working days for less than 1500pcs |

| Payment | L/C,T/T |

| thirty% advance payment,the balance paid before shipment | |

| Packing | Motor each have their own carton,the outer packing is a five-layer plywood boxes |

| Delivery | one)By air or sea or combined transportation |

| 2)Categorical:TNT,FEDEX,UPS,DHL |

Our Providers

Contact Us