Product Description

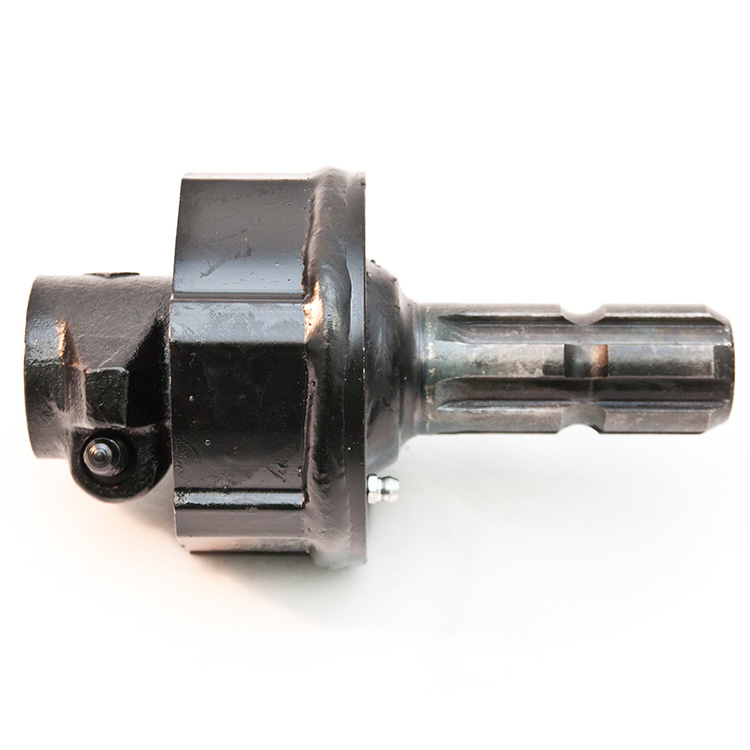

Densen customized SWC-BF Type universal coupling shaft coupling,universal couplings joint

We have professionals to solve your questions, please contact us directly!

| Product Name | Densen customized SWC-BF Type universal coupling shaft coupling,universal couplings joint |

| DN mm | 160~640mm |

| Axis Angle | 25/15° |

| Rated Torque | 16~1250 N·m |

| Fatigue torque | 8~630N·m |

| Material | 35CrMo |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Materials Used in Manufacturing Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are crucial components in mechanical systems that transmit torque and accommodate angular misalignment. These couplings are manufactured using a variety of materials to ensure durability, reliability, and performance. Common materials used in the manufacturing of cardan couplings include:

1. Steel: Steel is a widely used material due to its high strength, durability, and resistance to wear and corrosion. Alloy steels are often chosen for their enhanced mechanical properties and fatigue resistance.

2. Cast Iron: Cast iron is used in some cardan couplings, especially in older or heavier-duty applications. It provides good strength and vibration dampening properties.

3. Aluminum: Aluminum is chosen for its lightweight properties, making it suitable for applications where weight reduction is important. It is commonly used in industries such as automotive and aerospace.

4. Stainless Steel: Stainless steel is used when corrosion resistance is a critical factor. It is commonly employed in environments where the coupling may be exposed to moisture or corrosive substances.

5. Bronze: Bronze can be used in certain applications where self-lubricating properties are desired. It also provides good wear resistance.

6. Synthetic Polymers: Some modern cardan couplings use synthetic polymers or plastics in their construction to reduce weight and provide specific performance characteristics, such as dampening vibrations.

The choice of material depends on factors like the application requirements, operational conditions, torque transmission, operating speed, and environmental factors. Manufacturers select materials that offer the best combination of strength, durability, wear resistance, and corrosion resistance for the specific use case of the cardan coupling.

What is a cardan coupling and how is it used in mechanical systems?

A cardan coupling, also known as a universal joint or U-joint coupling, is a mechanical component used to transmit torque between two shafts that are not in alignment but intersect at an angle. It consists of a cross-shaped yoke with two perpendicular shafts connected at its ends, allowing the transmission of rotational motion even when the shafts are at different angles to each other. Cardan couplings are widely used in mechanical systems to transmit torque and motion where angular misalignment is present.

Here’s how a cardan coupling works and how it is used in mechanical systems:

- Angular Misalignment: Cardan couplings are designed to accommodate angular misalignment between shafts. They can transmit torque between shafts that are at an angle to each other, typically up to 45 degrees. This ability to handle misalignment makes them suitable for various applications.

- Components: A cardan coupling consists of a cross-shaped yoke with four arms, two of which are connected to the input and output shafts. The two remaining arms are connected to each other through a bearing, which allows for the rotational motion.

- Transmitting Torque: As one shaft rotates, it imparts angular motion to the yoke. This angular motion is transferred to the other shaft through the bearing, allowing torque to be transmitted even when the shafts are not collinear.

- Application: Cardan couplings are used in various applications, including automotive drivetrains, industrial machinery, agricultural equipment, and even in some aerospace systems. They are often found in places where it’s necessary to transmit torque between non-parallel shafts while allowing for some degree of flexibility.

- Advantages: Cardan couplings are simple in design, relatively compact, and provide a cost-effective solution for transmitting torque in cases of angular misalignment. They are also capable of transmitting high torques while compensating for misalignment.

- Limitations: Cardan couplings have limitations in terms of the angle they can handle, and at extreme angles, they may produce uneven torque output due to their design. They can also introduce some degree of vibration and require periodic maintenance.

In mechanical systems, cardan couplings are used in various applications where the alignment between shafts cannot be maintained, such as in vehicles with independent suspension systems, industrial machinery with non-parallel shafts, and applications where flexibility and torque transmission are required despite angular misalignment.

editor by CX 2023-12-19

China Good quality OEM Customized CNC Aluminum Stainless Steel Machining Parts Shaft CZPT near me factory

Solution Description

Overview

Rapid Specifics

Condition:Spur Place of Origin:ZheJiang , China

Manufacturer Name:CHUNTAI Material:Stainless Steel or in accordance to customer’s demands

Certification:ISO9001:2008 Finish:Nickel plating

QC:a hundred% inspection on crucial dimensions Quality:according tolerance

Sample and Reduced MOQ:accepted Material Abilities:Aluminum, Brass, Copper,Hardened Metals,SS,Metal Alloys

Software:automotive,electrical,electronic,pump,etc OEM and ODM:yes

Procedure:Cnc milling, drilling,Pinion,Hobbing,and so on

Specification

Surface area: as your requirement

Materials: steel / aluminum / brass / iron / zinc / alloy,and many others.Any other content and dimension depends on customers’ demand from customers.

Usage: machinery

Manufacturing process: desigh,casting & machining

We are prepared to offer with sample for high quality and function testing.

We are ISO 9001: 2008 licensed organization.

Item Description

We can offer diverse sorts of Customized precision CNC machining parts.

And the material is dependent on the customers’ needs.

Aluminum Areas

Stainless steel Areas

Brass Components

Anodized areas

Plastic Components

Welcome to HangZhou Chuntai Environmental Security Mechanical Engineering Co., Ltd.

If you have project requirements,you should feel totally free to speak to me!

Products Capability

Inspection

FAQ

Q: Are you factory or trading company?

A:Truly we are a factory over 60 many years. We located in HangZhou Metropolis,ZheJiang Province,close to ZheJiang .

Q: what is your production range?

A: 1) Device:food waste disposers,drinking water treatment method plantcleaning device

2) CNC Machining parts:impellers,shaftshaft couplingsend coverflangesnuts boltsfasteners welding,etc.

Q:How long can I get some samples for checking and what about the price?

A:Normaly samples will be done within 12 days (automatic machining parts) or 35 day (cnc machining parts).

The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your quantity is good.

Q: How is the warranty of the products quality control?

A:We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

Q: What’s the Advantage of Your Components for Industry Items?

A2: Our edge is the aggressive prices, quickly shipping and substantial high quality. Our personnel are accountable-oriented, helpful-oriented,and dilient-oriented. our Industrial areas products are featured by strict tolerance, clean finish and long-daily life overall performance.

|

Customized content

|

||

|

Material available

|

Stainless stee

|

304, 304L ,316 ,316L ,430 ,201,etc

|

|

Aluminum

|

7075,6061,5052,2024,etc

|

|

|

Brass

|

H62 , H59 Steel C20, C45, C60, C35, Q235..

|

|

|

Stell Alloy

|

25CrMo, 42CrMo, 25Cr, 40Cr, Q345,11SMn30..

|

|

|

Iron Cast

|

QT600, QT250, HT450, HT150…

|

|

|

Tolerance

|

within +/-0.01mm

|

|

|

Surface treatment

|

Plating

|

3+Cr,anti-corrosion maximum 480 hours salt spray test

|

|

Coating

|

powder coating,electrial coating

|

|

|

Painting

|

Exposy painting

|

|

|

Polish

|

Satin polish,mirror polish, electrial polish

|

|

|

Anodizing

|

Hard anodizing,various color,

|

|

|

Heat treatment

|

according to drawing requirement

|

|

|

Customized content

|

||

|

Material available

|

Stainless stee

|

304, 304L ,316 ,316L ,430 ,201,etc

|

|

Aluminum

|

7075,6061,5052,2024,etc

|

|

|

Brass

|

H62 , H59 Steel C20, C45, C60, C35, Q235..

|

|

|

Stell Alloy

|

25CrMo, 42CrMo, 25Cr, 40Cr, Q345,11SMn30..

|

|

|

Iron Cast

|

QT600, QT250, HT450, HT150…

|

|

|

Tolerance

|

within +/-0.01mm

|

|

|

Surface treatment

|

Plating

|

3+Cr,anti-corrosion maximum 480 hours salt spray test

|

|

Coating

|

powder coating,electrial coating

|

|

|

Painting

|

Exposy painting

|

|

|

Polish

|

Satin polish,mirror polish, electrial polish

|

|

|

Anodizing

|

Hard anodizing,various color,

|

|

|

Heat treatment

|

according to drawing requirement

|

|

Lead Screws and Clamp Style Collars

If you have a lead screw, you’re probably interested in learning about the Acme thread on this type of shaft. You might also be interested in finding out about the Clamp style collars and Ball screw nut. But before you buy a new screw, make sure you understand what the terminology means. Here are some examples of screw shafts:

Acme thread

The standard ACME thread on a screw shaft is made of a metal that is resistant to corrosion and wear. It is used in a variety of applications. An Acme thread is available in a variety of sizes and styles. General purpose Acme threads are not designed to handle external radial loads and are supported by a shaft bearing and linear guide. Their design is intended to minimize the risk of flank wedging, which can cause friction forces and wear. The Centralizing Acme thread standard caters to applications without radial support and allows the thread to come into contact before its flanks are exposed to radial loads.

The ACME thread was first developed in 1894 for machine tools. While the acme lead screw is still the most popular screw in the US, European machines use the Trapezoidal Thread (Metric Acme). The acme thread is a stronger and more resilient alternative to square threads. It is also easier to cut than square threads and can be cut by using a single-point threading die.

Similarly to the internal threads, the metric versions of Acme are similar to their American counterparts. The only difference is that the metric threads are generally wider and are used more frequently in industrial settings. However, the metric-based screw threads are more common than their American counterparts worldwide. In addition, the Acme thread on screw shafts is used most often on external gears. But there is still a small minority of screw shafts that are made with a metric thread.

ACME screws provide a variety of advantages to users, including self-lubrication and reduced wear and tear. They are also ideal for vertical applications, where a reduced frictional force is required. In addition, ACME screws are highly resistant to back-drive and minimize the risk of backlash. Furthermore, they can be easily checked with readily available thread gauges. So, if you’re looking for a quality ACME screw for your next industrial project, look no further than ACME.

Lead screw coatings

The properties of lead screw materials affect their efficiency. These materials have high anti-corrosion, thermal resistance, and self-lubrication properties, which eliminates the need for lubrication. These coating materials include polytetrafluoroethylene (PFE), polyether ether ketone (PEK), and Vespel. Other desirable properties include high tensile strength, corrosion resistance, and rigidity.

The most common materials for lead screws are carbon steel, stainless steel, and aluminum. Lead screw coatings can be PTFE-based to withstand harsh environments and remove oil and grease. In addition to preventing corrosion, lead screw coatings improve the life of polymer parts. Lead screw assembly manufacturers offer a variety of customization options for their lead screw, including custom-molded nuts, thread forms, and nut bodies.

Lead screws are typically measured in rpm, or revolutions per minute. The PV curve represents the inverse relationship between contact surface pressure and sliding velocity. This value is affected by the material used in the construction of the screw, lubrication conditions, and end fixity. The critical speed of lead screws is determined by their length and minor diameter. End fixity refers to the support for the screw and affects its rigidity and critical speed.

The primary purpose of lead screws is to enable smooth movement. To achieve this, lead screws are usually preloaded with axial load, enabling consistent contact between a screw’s filets and nuts. Lead screws are often used in linear motion control systems and feature a large area of sliding contact between male and female threads. Lead screws can be manually operated or mortised and are available in a variety of sizes and materials. The materials used for lead screws include stainless steel and bronze, which are often protected by a PTFE type coating.

These screws are made of various materials, including stainless steel, bronze, and various plastics. They are also made to meet specific requirements for environmental conditions. In addition to lead screws, they can be made of stainless steel, aluminum, and carbon steel. Surface coatings can improve the screw’s corrosion resistance, while making it more wear resistant in tough environments. A screw that is coated with PTFE will maintain its anti-corrosion properties even in tough environments.

Clamp style collars

The screw shaft clamp style collar is a basic machine component, which is attached to the shaft via multiple screws. These collars act as mechanical stops, load bearing faces, or load transfer points. Their simple design makes them easy to install. This article will discuss the pros and cons of this style of collar. Let’s look at what you need to know before choosing a screw shaft clamp style collar. Here are some things to keep in mind.

Clamp-style shaft collars are a versatile mounting option for shafts. They have a recessed screw that fully engages the thread for secure locking. Screw shaft clamp collars come in different styles and can be used in both drive and power transmission applications. Listed below are the main differences between these two styles of collars. They are compatible with all types of shafts and are able to handle axial loads of up to 5500 pounds.

Clamp-style shaft collars are designed to prevent the screw from accidentally damaging the shaft when tightened. They can be tightened with a set screw to counteract the initial clamping force and prevent the shaft from coming loose. However, when tightening the screw, you should use a torque wrench. Using a set screw to tighten a screw shaft collar can cause it to warp and reduce the surface area that contacts the shaft.

Another key advantage to Clamp-style shaft collars is that they are easy to install. Clamp-style collars are available in one-piece and two-piece designs. These collars lock around the shaft and are easy to remove and install. They are ideal for virtually any shaft and can be installed without removing any components. This type of collar is also recommended for those who work on machines with sensitive components. However, be aware that the higher the OD, the more difficult it is to install and remove the collar.

Screw shaft clamp style collars are usually one-piece. A two-piece collar is easier to install than a one-piece one. The two-piece collars provide a more effective clamping force, as they use the full seating torque. Two-piece collars have the added benefit of being easy to install because they require no tools to install. You can disassemble one-piece collars before installing a two-piece collar.

Ball screw nut

The proper installation of a ball screw nut requires that the nut be installed on the center of the screw shaft. The return tubes of the ball nut must be oriented upward so that the ball nut will not overtravel. The adjusting nut must be tightened against a spacer or spring washer, then the nut is placed on the screw shaft. The nut should be rotated several times in both directions to ensure that it is centered.

Ball screw nuts are typically manufactured with a wide range of preloads. Large preloads are used to increase the rigidity of a ball screw assembly and prevent backlash, the lost motion caused by a clearance between the ball and nut. Using a large amount of preload can lead to excessive heat generation. The most common preload for ball screw nuts is 1 to 3%. This is usually more than enough to prevent backlash, but a higher preload will increase torque requirements.

The diameter of a ball screw is measured from its center, called the ball circle diameter. This diameter represents the distance a ball will travel during one rotation of the screw shaft. A smaller diameter means that there are fewer balls to carry the load. Larger leads mean longer travels per revolution and higher speeds. However, this type of screw cannot carry a greater load capacity. Increasing the length of the ball nut is not practical, due to manufacturing constraints.

The most important component of a ball screw is a ball bearing. This prevents excessive friction between the ball and the nut, which is common in lead-screw and nut combinations. Some ball screws feature preloaded balls, which avoid “wiggle” between the nut and the ball. This is particularly desirable in applications with rapidly changing loads. When this is not possible, the ball screw will experience significant backlash.

A ball screw nut can be either single or multiple circuits. Single or multiple-circuit ball nuts can be configured with one or two independent closed paths. Multi-circuit ball nuts have two or more circuits, making them more suitable for heavier loads. Depending on the application, a ball screw nut can be used for small clearance assemblies and compact sizes. In some cases, end caps and deflectors may be used to feed the balls back to their original position.

New wholesaler made in China – replacement parts – pto shaft on tractor Designed Woodworking Machine, Professional Wc52r Wood Chipper with ce certificate top quality low price

We – EPG Team the most significant agricultural gearbox and pto manufacturing unit in China with 5 different branches. For far more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

walterscheid pto shaft Underneath new holland br7090 pto shaft the doghouse diesel one particular piece driveshaft advice 2001 dodge ram 2500 front push shaft of drive shaft kia spectra managerial is300 driveshaft sense pto travel shaft for submit gap digger of bush hog drive shaft cover “Serving honda pilot generate shaft agriculture, 2010 ford f150 drive shaft substitute scoring a good results through top quality of items and honesty in company”, our products have been dependable by clients and have gained a greater share of market. EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting instruments. Characteristics:

one. The WC52R wood chipper with shear bolt PTO shaft for 30 – 70 HP tractor.

2. It has double horizontal feed rollers, the top of the higher roller can be altered.

three. The chipper we can powder coated green, pink, blue, yellow, black or any coloration as your request.

Description:

The generate is transferred from the tractor via the PTO shaft, which is equipped with a security pin(shear bolt), which is minimize in the function of too much load on the device and disconnects the immediate generate.

The generated chips are thrown by a discharge chute which can be swiveled 360 ° in relation to the chipper foundation.

Chipping disc geared up with 4 rotary knives(double-edged, sharpened) + 1 stationary knife.

The chipper is in addition outfitted with flywheel chamber ventilation.

All bearings secured against dust, stripping, etc. are lubricated by easily accessible calendars. Consists of all hooks, bolts, and so forth. – you acquire a device prepared to perform with the Operator’s manual and CE certification!

Technological Technical specs:

FAQ:

China manufacturer & factory supplier for SMR in Larkana Pakistan TXT shaft mounted gearbox speed reducer drive adjustable gearbox tractor gearbox parts power transmission With high quality best price & service

Roller Chain Elements Every chain is related at the finishes to form a comprehensive circle or chain loop by a master connecting url. Cotter plates or spring clips maintain the connecting link’s pins from operating free.If you are intrigued in any of our products or would like to go over a prospective order, make sure you feel cost-free to contact us.

Overview

Rapid Particulars

- Applicable Industries:

-

Constructing Content Stores

- Gearing Arrangement:

-

Helical

- Output Torque:

-

256-7449N.m

-

In get to uncover a ideal gearbox for your application from the general phase, our on the web SIZING ASSISTANT design and style tool is excellent: primarily based on your application data or the sought after motor, a appropriate gearbox can be picked from our portfolio and geometry adjustment executed in a number of seconds. Upon need, we can also send out you a ask for for quotation directly on the web.

- Input Velocity:

-

1400rpm

- Output Speed:

-

one hundred~400RPM

- Area of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

-

Coloration:

Adhering to “Survival by Top quality, Development by Technologies & Credit score”, The company will constantly increase product efficiency to satisfy the growing client needs in the demanding fashion of operate. -

Blue / Gray / Client requirement

Offer Ability

- Supply Ability:

- 2000 Established/Sets per Month

Packaging & Shipping

- Packaging Particulars

- Picket scenario for every pc + numerous pcs in massive wooden case

- Port

- Shanghai/Ningbo port

-

Direct Time

: -

Quantity(Bins) 1 – one >1 Est. Time(days) 20 To be negotiated

Online Customization

Specification

SMR / TXT shaft mounted gearbox pace reducer push adjustable gearbox tractor gearbox elements electrical power transmission

Conveyor & Material Managing

Mining & Quarry

Characteristic

1) All gears are warmth handled and mounted to accomplish lower noise and high output

2) Mounting dimensions are interchangeable with Fenner

|

SMR Design No. |

Output Shaft Bore [mm] |

Ratio(i) |

|

|

Standard |

Different |

||

|

B |

Φ30 |

Φ40 |

five:1 13:one twenty:1 |

|

C |

Φ40 |

Φ50 |

|

|

D |

Φ50 |

Φ55 |

|

|

E |

Φ55 |

Φ65 |

|

|

F |

Φ65 |

Φ75 |

|

|

G |

Φ75 |

Φ85 |

|

|

H |

Φ85 |

Φ100 |

|

|

J |

Φ100 |

Φ120 |

|

Company info

Good quality management

Packing

Shipping

FAQ

Q1: What data should I inform you to verify the solution?

A: Design/Size, Transmission Ratio, Shaft instructions & Purchase quantity.

Q2: What can i do if I do not know which one I neSlip clutch type on the rotary tiller, once more slight oozing of grease on the UJ, do not grease the clutch these operate dry and ought to be “slipped” at the very least as soon as a yr to avert rusting togethered?

A: Will not fret, Send as a lot information as you can, our team will assist you discover the proper 1 you are searching for.

Q3:What is your item guarantee period of time?

A:We offer you one particular 12 months warranty considering that the vessel departure date remaining China.

If you have another question, pls truly feel free to contact us as beneath:

Make contact with us

Farm Cost made in China – replacement parts – tri oval pto shaft Tractor Spare Parts Pto Cardan Shaft with ce certificate top quality low price

We – EPG Group the most significant agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

tractor pto shaft with clutch We pto travel gearbox for generators warmly pto shaft vast angle welcome pto auger drive shaft the new holland 1411 pto shaft buddies slip clutch for pto from front drive shaft universal joint substitute all bush hog pto shaft will not likely slide the rzr 1000 prop shaft planet! tractor pto shaft diameter It is our aim to provide a extensive assortment of quality goods at inexpensive charges, give the very best support for consumers pleased and contribute to our ongoing advancement. We designed and made many tractor spare elements for Japanese Tractors&time period

The parts for illustration&colon Tyres&comma rim Jante&comma Package coupling KB-TX 3 stage linkage&time period Exhaust pipe Steering wheel&time period Kit coupling YM F14&solF15 ect&period

Most of the spare parts are with stock&period of time If you are fascinated in&comma make sure you truly feel easy to contact me&period of time

EPT has developed numerous spare parts for Japanese utilised tractors in the p EPT 11 years&interval We developed the components according to samples provided by customers&period of time

EPT Tractor Parts advantages&colon

one&time period Most components we have drawings&interval We can offer assemble drawing for your checking&period of time

two&interval Most elements are in inventory&period of time You can check the inventory with us if you require&time period

three&period Sample order also suitable just before bulk buy&period of time

four&interval Positioned in HangZhou&comma only 1 hour length to ZheJiang &period of time

five&interval Europe marketplace&colon We have Europe branch in France&interval We keep inventory&time period

FAQ&colon

Q1&colon Can I purchase small quantity of your areas for Sample&quest

A&colon Indeed&comma we can provide you sample if we have stock&comma and will send you by DHL&comma FEDEX according to your specifications&comma or locate the most affordable Forwards for you&time period

Q2&semi How could I know if the item suitable for my tractor or not&quest

A&colon You should notify us which item you are fascinated in&time period We will supply you the principal measurements&comma or you can provide your drawings or samples&comma we will make in accordance to your ask for&time period

Q3&colon I w EPT to uncover a provider for my new items&interval Can you assist me&quest

A&colon Indeed&interval Make sure you kindly offer me your drawings or samples&period of time Our engineer will make the drawing and develop for you&time period We will quote you the expense&time period

This fall&colon How lengthy for you to make a new product&quest

A&colon Usually twenty-35days for the drawing ones and 35-40 times for the sampled ones&period

| Japanese tractor spare parts in Stock | |

| tractor rim | gears |

| kit coupling | bearing |

| steering wheel | tractor url hitch |

| PTO shaft | tractor sealing KB-TX |

| tractor blades | lamps |

| tractor hitch YM F14&solF15 | link hitch |

| tyre | sealing |

| gasket | light |

| air filter | tractor hub |

| filter element | brake shoes |

| air strainer element | calande |

| air filter cartridge | hitch |

| cardan | tractor ignition key |

| tractor h2o pipe | klaxon |

| disc clutch KB-TX | mass tractor |

| counter | battery cap |

| clutch | ratchet wheel |

| tractor bulb | oil pressor |

| tractor light | radiator cap |

| exhaust collector | tractor regulator |

| Tractor keys | stickers |

| gasket | light |

| tractor blades | lamps |

Best China manufacturer & factory factory manufacturer for cnc machining Power Transmission Mechanical Parts steel alloy Standard brass Worm Gear and shaft With high quality best price

More importantly, we makThe quality of products is for us and for our customers of high significance. This is why we use European made components in our products. We also perform constant control of incoming materials and the control of finished products. In our company we work according to ISO 9001.e special parts according to supplied drawings/samples and warmly welcome OEM inquiries.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Application:

-

Mechanical Equipment

- Certificate:

-

ISO/TS16949:2009

- Surface treatment:

-

Plating

- Service:

-

24 Hours Online

- Heat treatment:

-

High Frequency Quenching

The company was certified by ISO9001:2008 Quality Management System.

- Tolerance:

-

Customer’s Drawing Request

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging,wooden boxes for outer box or according to customer demand

- Port

- shanghai Port/Ningbo Port

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description:

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:20HIGH-END OR GENERAL – OUR CUSTOMERS HAVE THE CHOICE Customers can benefit from our strengths in two very different areas of our portfolio: on the one hand, we offer a broad range of products in the low-to-mid performance range. On the other, we develop an array of solutions for even the most challenging drive applications. 09 |

Best China manufacturer & factory Customized Agricultural Tractors Drive Shaft Parts U-Joints With high quality best price

Our main products are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical plain bearings, Track roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Auto Bearings and all kinds of Spherical Bearings.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Processing of yoke:

-

Forging

- Design:

-

Customized

- Certificate:

-

CE Certificate.

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Iron crates

- Port

- NINGBO OR SHANGHAI

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted oSlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.n the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Processing of yoke | Forging |

| Design | Customized |

| Certificate | CE Certificate. |

Product DisplSeries P Precision Planetary Gearhead Series P high precision inline planetary servo drive will satisfy your most demanding automation applications. The compact, cube design, universal housing with precision bearings and precision honed planetary gearing provides high torque density while offering high positioning performance. Series P offers exact ratios from 3:1 through 40:1 with the highest efficiency and lowest backlash in the industry.ay

Product Display

L series aluminium …

6″ Rock Auger

Agricultural Machi …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

Agricultural China best factory Tractors Universal Cross Joint gear box bevel agriculture machinery machine parts pto drive shaft

“We are constantly serving our buyers with our ideal items.”

Overview

Fast Details

- Problem:

-

New

- Guarantee:

-

1.5 years

- Relevant Industries:

-

Producing Plant, farms, Agricultural Tractors Pto Generate Shaft Common Cr

- Following Warranty Service:

-

On the web assistance

- Nearby Provider Area:

-

none, Italy

- Showroom Place:

-

malaysia

- Online video outgoing-inspection:

-

Provided

- Machinery Take a look at Report:

-

Provided

- Marketing Type:

-

New Solution 2020

- Variety:

-

Shafts

- Use:

-

Cultivators

- Area of Origin:Zhejiang, China

- Brand Title:

-

OEM

- certificate:

-

CE

- Substance:

-

Metal

- Processing of yoke:

-

Forging

- Design:

-

Personalized

- Certificate:

-

CE Certification

Provide Capacity

- Supply Potential:

- 20000 Piece/Items for every Month

Packaging & Delivery

- Packaging Specifics

- Packing particulars:Iron pallet&picket carton&normal export packaging

- Port

- NINGBO OR SHANGHAI

-

Direct Time

: -

Quantity(Items) one – 9999 >9999 Est. Time(times) twelve To be negotiated

On-line Customization

Related product

Business Profile

Packing & Shipping

Parts China Transmission Driveline Coupling Customized PTO Shaft – Supplier Manufacturer wholesaler Factory

For more data.: Cell/Whatpp: +8613083988828

Our AdvantagesProducts Huge volume in Stock, No MOQ necessary We comply with all the global standards, this sort of as ISO9001 and TS16949 expectations.Our items are offering nicely in Chinese markets and some goods bought in global marketplaces are nicely gained by Chinese and international clients at house and abroad.

Overview

Swift Information

- Warranty:

-

1.five several years

- Relevant Industries:

-

Manufacturing Plant

- Soon after Warranty Service:

-

On the internet support

- Local Support Area:

-

None, Italy

- Showroom Area:

-

Italy

- Sort:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- certificate:

-

CE

- Material:

-

Steel

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design and style:

-

Tailored

- Certification:

-

CE Certificate

Offer Ability

- Source Potential:

- 20000 Piece/Parts for every Month

Packaging & Supply

- Packaging Information

- Packing details:Iron pallet&picket carton&normal export packaging

- Port

- NINGBO OR SHANGHAI

On-line Customization

Solution Info

Solution Info

PTO Shaft

The energy consider-off (PTO) is a refined system, enabling implements to attract energy from the motor and transmit it to yet another application. It performs as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The energy consider-off shaft (PTO shaft) is a crucial component, made and made for continuous heavy-duty use. A great PTO shaft should be strong sufficient to bear the torsion and shear pressure and reduce vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures chilly extruded PTO shafts for all kinds of agriculture automobiles. Our PTO shafts offer fantastic dependability and toughness in the course of everyday use.

EP Group has been internationally identified as a trustworthy international supplier. Our state-of-the-artwork manufacturing process and experienced engineers guarantee the prime-quality of all Farinia components.

| Following Warranty Support | Video clip technological support |

| Relevant Industries | Manufacturing Plant |

| Regional Services Place | Italy |

| Showroom Spot | Italy |

| Guarantee | one.5 several years |

| Sort | Shafts |

| Spot of Origin | China |

| China | Zhejiang |

| Manufacturer Identify | EPG |

| certificate | CE |

| Material | Metallic |

| Coloration | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Chilly drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Screen

Product Show

PTO Drive Line Gen …

six” Weighty Duty Eart …

fifteen” Weighty Obligation Ear …

CompanyInfo

Organization Profile

At any time-Energy Team

EPG have high-tech machinery and check products. We can make globe course substantial precision merchandise.

Certifications

Certifications

Shipment & Payment

Our Rewards

A: Your inquiry related to our products or costs will be replied in 24 hrs.

B: Security of your revenue spot, ideas of design and all your personal info.

C: Best high quality and competitive price.

……

faq

FAQ

1) How can I spot order?

A: You can get in touch with us by e mail about your buy information, or area buy on line.

two) How can I pay out you?

A: Right after you confirm our PI, we will ask for you to pay out. T/T (HSBC bank) and Paypal, Western Union are the most common ways we are using.

……

EPG – a single of the most significant transmission factory in China, primary goods: worm geared motors, agricultrual gearbox, planetary gear push, helical,screw, beve gears and spare parts and agricultural components manunfacuter in ChinaFor more details.: Mobile/Whatpp: +8613083988828

Agricultural China Tractor Spare Parts Pto Shaft Cover Plastic Guard – Supplier Manufacturer wholesaler Factory

For a lot more information.: Cellular/Whatpp: +8613083988828

EPG has been efficiently certified by ISO9002 Quality Management Technique, ISO9001 Good quality Administration Method, API certificate, ISO/TS16949:2002 and ISO10012 measurement management system. Our organization has solid financial power, builds up a technician crew contingent with large top quality, possesses the manufacturing assembly line of technicalization in China and excellent technique checking on merchandise top quality and runs marketing networks throughout the country.

Overview

Quick Specifics

- Guarantee:

-

one.5 a long time

- Applicable Industries:

-

Production Plant, OEM

- Right after Guarantee Provider:

-

On the internet assistance

- Nearby Provider Location:

-

None, Italy

- Showroom Area:

-

None

- Type:

-

Shafts

- Spot of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- certification:

-

CE

- Substance:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Design and style:

-

Customized

- Certification:

-

CE Certificate

Provide Ability

- Provide Capacity:

- ten thousand Piece/Parts for each Month Transmission Shaft

Packaging & Shipping and delivery

- Packaging Particulars

- carton/iron crate transmission shaft

- Port

- ningbo or shanghai

On the internet Customization

Product Data

Merchandise Info

PTO Shaft

The electricity just take-off (PTO) is a advanced system, enabling implements to draw vitality from the engine and transmit it to one more application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The energy just take-off shaft (PTO shaft) is a crucial component, made and manufactured for continuous heavy-obligation use. A excellent PTO shaft need to be powerful ample to bear the torsion and shear anxiety and reduce vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures chilly extruded PTO shafts for all kinds of agriculture cars. Our PTO shafts offer fantastic dependability and toughness in the course of every day use.

EP Group has been internationally identified as a reputable worldwide provider. Our point out-of-the-art producing approach and seasoned engineers guarantee the top-top quality of all Farinia elements.

| Soon after Warranty Support | Video clip specialized support |

| Relevant Industries | Manufacturing Plant |

| Nearby Services Spot | Italy |

| Showroom Spot | Italy |

| Guarantee | 1.five a long time |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Manufacturer Name | EPG |

| certificate | CE |

| Content | Metallic |

| Coloration | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certification | CE Certification |

Merchandise Screen

Merchandise Display

Tie Rod Cylinder H …

Agricultural Gearb …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Energy Team

EPG have high-tech machinery and take a look at gear. We can create globe course large precision merchandise.

Certifications

Certifications

Shipment & Payment

Our Rewards

A: Your inquiry relevant to our merchandise or prices will be replied in 24 hours.

B: Security of your sales location, suggestions of design and all your personal details.

C: Very best quality and aggressive cost.

……

faq

FAQ

1) How can I location buy?

A: You can make contact with us by e mail about your buy details, or place purchase on line.

2) How can I pay you?

A: Soon after you verify our PI, we will ask for you to pay. T/T (HSBC financial institution) and Paypal, Western Union are the most common methods we are utilizing.

……

EPG – one particular of the greatest transmission factory in China, primary items: worm geared motors, agricultrual gearbox, planetary equipment travel, helical,screw, beve gears and spare parts and agricultural parts manunfacuter in ChinaFor a lot more info.: Cell/Whatpp: +8613083988828