Product Description

| Product Name | Cardan Shaft |

| Product Model | SWC-I75A-335+40 |

| Main Material | 35CrMo or 45# Steel |

| Nominal Torque | 500 N.M |

| Normal Length | 335 mm |

| Length Compensation | 40 mm |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Materials Used in Manufacturing Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are crucial components in mechanical systems that transmit torque and accommodate angular misalignment. These couplings are manufactured using a variety of materials to ensure durability, reliability, and performance. Common materials used in the manufacturing of cardan couplings include:

1. Steel: Steel is a widely used material due to its high strength, durability, and resistance to wear and corrosion. Alloy steels are often chosen for their enhanced mechanical properties and fatigue resistance.

2. Cast Iron: Cast iron is used in some cardan couplings, especially in older or heavier-duty applications. It provides good strength and vibration dampening properties.

3. Aluminum: Aluminum is chosen for its lightweight properties, making it suitable for applications where weight reduction is important. It is commonly used in industries such as automotive and aerospace.

4. Stainless Steel: Stainless steel is used when corrosion resistance is a critical factor. It is commonly employed in environments where the coupling may be exposed to moisture or corrosive substances.

5. Bronze: Bronze can be used in certain applications where self-lubricating properties are desired. It also provides good wear resistance.

6. Synthetic Polymers: Some modern cardan couplings use synthetic polymers or plastics in their construction to reduce weight and provide specific performance characteristics, such as dampening vibrations.

The choice of material depends on factors like the application requirements, operational conditions, torque transmission, operating speed, and environmental factors. Manufacturers select materials that offer the best combination of strength, durability, wear resistance, and corrosion resistance for the specific use case of the cardan coupling.

How do you properly install and maintain a cardan coupling in machinery?

Proper installation and maintenance of a cardan coupling are crucial to ensure its reliable performance and longevity:

- Installation:

- Align the shafts properly before connecting the coupling to minimize initial misalignment.

- Ensure that the universal joints are in phase, meaning their yokes are in the same orientation to prevent uneven torque transmission.

- Follow the manufacturer’s instructions for torque specifications while tightening bolts and fasteners to prevent overloading or loosening during operation.

- Make sure the coupling is properly centered and balanced to avoid vibrations.

- Check for any obstructions or interference that might affect the movement of the coupling.

- Maintenance:

- Regularly inspect the coupling for signs of wear, such as cracks, corrosion, or damaged components.

- Monitor the alignment of the shafts to detect any misalignment that might occur over time.

- Lubricate the universal joints and bearings as recommended by the manufacturer to reduce friction and wear.

- Replace worn or damaged components promptly to prevent further deterioration and potential coupling failure.

- Perform vibration analysis and balancing to ensure the coupling operates smoothly and doesn’t contribute to excessive vibrations in the machinery.

- Regularly check for any signs of overheating, which might indicate inadequate lubrication or other issues.

- Keep the coupling area clean from debris, dirt, and contaminants that could affect its performance.

By following proper installation procedures and conducting regular maintenance checks, you can maximize the efficiency and reliability of a cardan coupling in machinery.

editor by CX 2024-04-16

China Professional Flexible Stainless Steel Spider Couplings Balancing Machine for Cardan Shafts

Product Description

| Product Name | Cardan Shaft |

| Product Model | SWC-I75A-335+40 |

| Main Material | 35CrMo or 45# Steel |

| Nominal Torque | 500 N.M |

| Normal Length | 335 mm |

| Length Compensation | 40 mm |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Diagnosing and Troubleshooting Cardan Coupling Issues

Diagnosing and troubleshooting issues related to cardan couplings in machinery systems involves a systematic approach:

- Visual Inspection: Examine the cardan coupling for signs of wear, damage, misalignment, or corrosion. Look for any unusual noises or vibrations.

- Check Lubrication: Inspect the lubrication system and ensure proper lubricant levels. Inadequate lubrication can lead to premature wear.

- Monitor Performance: Use sensors and monitoring systems to track the performance of the cardan coupling in real-time. Analyze data for anomalies.

- Measure Alignment: Check for proper alignment between the input and output shafts. Misalignment can lead to increased wear and reduced efficiency.

- Check for Unusual Noises: Listen for any unusual noises during operation, such as grinding, squeaking, or knocking sounds.

- Inspect Components: Examine the individual components of the cardan coupling, including the universal joints and shafts, for signs of wear or damage.

- Perform Load Analysis: Evaluate the operating conditions and loads to ensure they are within the specified limits of the cardan coupling.

- Review Maintenance Records: Refer to maintenance records to ensure that the cardan coupling has been properly maintained and serviced.

- Consult Manufacturer Guidelines: Follow the manufacturer’s guidelines for troubleshooting and diagnostics specific to the cardan coupling model.

By following these steps, operators and maintenance personnel can effectively diagnose and troubleshoot cardan coupling issues, ensuring the reliable and efficient operation of machinery systems.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-04-13

China supplier Custom Wholesale Cardan Shafts High Precision Wsp Small Cross Shaft Universal Coupling

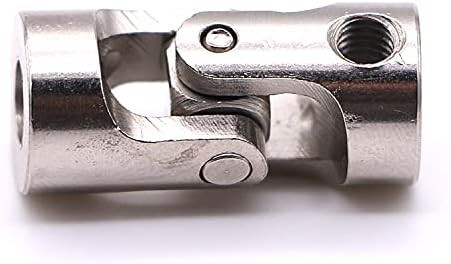

Product Description

Custom wholesale cardan shafts high precision WSP small cross shaft universal coupling

Description:

Cardan shaft is widely used in rolling mill, punch, straightener, crusher, ship drive, paper making equipment, common machinery, water pump equipment, test bench, and other mechanical applications.

Structure features:

1. It is suitable for transmission coupling space on the same plane of 2 axis angle beta β≤45°, the nominal torque transmission 11.2-1120N.

2. The WSD type is a single cross universal coupling, and the WS type is a double cross universal coupling, the WSS type is a telescopic universal coupling.

3. Each section is between the largest axis angle of 45º.

4. The finished hole H7, according to the requirements of keyseating, has 6 square holes and a square hole.

5. The angle between the 2 axes is allowed in a limited range as the work requirements change.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Phasing in Cardan Couplings and Its Impact on Performance

The concept of phasing in cardan couplings refers to the alignment of the universal joints’ yokes or flanges on the input and output shafts. Proper phasing is essential to minimize angular misalignment and maintain smooth rotational motion. When the yokes of the universal joints are not aligned correctly, it can result in uneven torque transmission, increased wear, and vibrations.

Phasing affects the performance of cardan couplings in several ways:

- Uniform Torque Transmission: Proper phasing ensures that torque is evenly distributed between the input and output shafts, reducing the risk of overloading individual universal joints.

- Reduced Vibrations: Correctly phased universal joints minimize angular misalignment, which helps reduce vibrations and noise in the machinery system.

- Extended Lifespan: Improved phasing leads to reduced wear and stress on the universal joint components, extending the overall lifespan of the coupling.

- Efficient Power Transmission: Proper phasing contributes to efficient power transmission by minimizing energy losses due to misalignment.

To achieve proper phasing, manufacturers often provide guidelines or marks on the coupling components to ensure accurate alignment. It’s essential to follow these guidelines during installation and any maintenance or adjustments to maintain optimal performance and reliability of the cardan coupling.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2024-04-12

China OEM Custom Wholesale Cardan Shafts High Precision Wsp Small Cross Shaft Universal Coupling

Product Description

Custom wholesale cardan shafts high precision WSP small cross shaft universal coupling

Description:

Cardan shaft is widely used in rolling mill, punch, straightener, crusher, ship drive, paper making equipment, common machinery, water pump equipment, test bench, and other mechanical applications.

Structure features:

1. It is suitable for transmission coupling space on the same plane of 2 axis angle beta β≤45°, the nominal torque transmission 11.2-1120N.

2. The WSD type is a single cross universal coupling, and the WS type is a double cross universal coupling, the WSS type is a telescopic universal coupling.

3. Each section is between the largest axis angle of 45º.

4. The finished hole H7, according to the requirements of keyseating, has 6 square holes and a square hole.

5. The angle between the 2 axes is allowed in a limited range as the work requirements change.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Impact of Size and Design on Cardan Coupling Performance and Durability

The size and design of a cardan coupling play a crucial role in determining its performance and durability across various applications:

- Load Capacity: Larger and more robust cardan couplings are generally designed to handle higher torque and load capacities, making them suitable for heavy-duty applications.

- Flexibility: The design of the coupling’s universal joint and its flexibility affect how well it can accommodate angular misalignment while maintaining smooth power transmission.

- Alignment Tolerance: Well-designed cardan couplings have better alignment tolerances, allowing them to operate efficiently even in conditions with slight misalignment.

- Materials: The choice of materials impacts the coupling’s strength, corrosion resistance, and overall durability, especially in harsh environments.

- Bearing Arrangement: The bearing arrangement within the coupling affects its ability to withstand both axial and radial forces, which is crucial for stability.

- Sealing: Effective sealing mechanisms prevent contaminants from entering the coupling, ensuring smooth operation and preventing premature wear.

- Dynamic Balance: Proper dynamic balance reduces vibrations and stress on connected components, contributing to extended coupling life.

- Lubrication: The design should allow for adequate lubrication, which is essential for reducing friction and wear.

- Installation and Maintenance: A well-designed coupling should be easy to install and maintain, with accessible lubrication points and inspection areas.

Ultimately, the size and design of a cardan coupling should be carefully matched to the specific requirements of the application to ensure optimal performance, reliability, and longevity.

Materials Used in Manufacturing Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are crucial components in mechanical systems that transmit torque and accommodate angular misalignment. These couplings are manufactured using a variety of materials to ensure durability, reliability, and performance. Common materials used in the manufacturing of cardan couplings include:

1. Steel: Steel is a widely used material due to its high strength, durability, and resistance to wear and corrosion. Alloy steels are often chosen for their enhanced mechanical properties and fatigue resistance.

2. Cast Iron: Cast iron is used in some cardan couplings, especially in older or heavier-duty applications. It provides good strength and vibration dampening properties.

3. Aluminum: Aluminum is chosen for its lightweight properties, making it suitable for applications where weight reduction is important. It is commonly used in industries such as automotive and aerospace.

4. Stainless Steel: Stainless steel is used when corrosion resistance is a critical factor. It is commonly employed in environments where the coupling may be exposed to moisture or corrosive substances.

5. Bronze: Bronze can be used in certain applications where self-lubricating properties are desired. It also provides good wear resistance.

6. Synthetic Polymers: Some modern cardan couplings use synthetic polymers or plastics in their construction to reduce weight and provide specific performance characteristics, such as dampening vibrations.

The choice of material depends on factors like the application requirements, operational conditions, torque transmission, operating speed, and environmental factors. Manufacturers select materials that offer the best combination of strength, durability, wear resistance, and corrosion resistance for the specific use case of the cardan coupling.

How do you properly install and maintain a cardan coupling in machinery?

Proper installation and maintenance of a cardan coupling are crucial to ensure its reliable performance and longevity:

- Installation:

- Align the shafts properly before connecting the coupling to minimize initial misalignment.

- Ensure that the universal joints are in phase, meaning their yokes are in the same orientation to prevent uneven torque transmission.

- Follow the manufacturer’s instructions for torque specifications while tightening bolts and fasteners to prevent overloading or loosening during operation.

- Make sure the coupling is properly centered and balanced to avoid vibrations.

- Check for any obstructions or interference that might affect the movement of the coupling.

- Maintenance:

- Regularly inspect the coupling for signs of wear, such as cracks, corrosion, or damaged components.

- Monitor the alignment of the shafts to detect any misalignment that might occur over time.

- Lubricate the universal joints and bearings as recommended by the manufacturer to reduce friction and wear.

- Replace worn or damaged components promptly to prevent further deterioration and potential coupling failure.

- Perform vibration analysis and balancing to ensure the coupling operates smoothly and doesn’t contribute to excessive vibrations in the machinery.

- Regularly check for any signs of overheating, which might indicate inadequate lubrication or other issues.

- Keep the coupling area clean from debris, dirt, and contaminants that could affect its performance.

By following proper installation procedures and conducting regular maintenance checks, you can maximize the efficiency and reliability of a cardan coupling in machinery.

editor by CX 2024-03-18

China wholesaler Flexible Stainless Steel Spider Couplings Balancing Machine for Cardan Shafts

Product Description

| Product Name | Cardan Shaft |

| Product Model | SWC-I75A-335+40 |

| Main Material | 35CrMo or 45# Steel |

| Nominal Torque | 500 N.M |

| Normal Length | 335 mm |

| Length Compensation | 40 mm |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Signs of Wear or Damage in a Cardan Coupling and Detection Methods

Over time, cardan couplings can experience wear or damage that may impact their performance. Some common signs of wear or damage include:

- Vibration: Excessive vibration during operation can indicate misalignment or worn components in the cardan coupling.

- Noise: Unusual noises such as clunking, knocking, or rattling can indicate worn bearings or other components.

- Increased Play: If there is noticeable play or backlash in the coupling, it may suggest worn or loose components.

- Reduced Performance: A decrease in torque transmission or power transfer efficiency can indicate wear in the coupling.

- Leakage: In the case of lubricated cardan couplings, leakage of lubricant may occur due to worn seals or damaged components.

To detect these signs of wear or damage, various methods can be employed:

- Visual Inspection: Regularly inspect the coupling for any visible signs of wear, corrosion, or damage.

- Vibration Analysis: Use vibration analysis tools to monitor vibration levels and detect any irregularities.

- Noise Analysis: Listen for unusual noises during operation, which may indicate worn or misaligned components.

- Torque Measurement: Monitor the torque transmitted through the coupling and compare it with expected values.

- Play Measurement: Check for any play or backlash in the coupling by manually moving the shafts.

- Lubricant Analysis: Analyze the condition of the lubricant for any contamination or signs of wear.

Regular maintenance and inspections are crucial for detecting and addressing wear or damage in cardan couplings before they lead to more severe issues or failures.

Materials Used in Manufacturing Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are crucial components in mechanical systems that transmit torque and accommodate angular misalignment. These couplings are manufactured using a variety of materials to ensure durability, reliability, and performance. Common materials used in the manufacturing of cardan couplings include:

1. Steel: Steel is a widely used material due to its high strength, durability, and resistance to wear and corrosion. Alloy steels are often chosen for their enhanced mechanical properties and fatigue resistance.

2. Cast Iron: Cast iron is used in some cardan couplings, especially in older or heavier-duty applications. It provides good strength and vibration dampening properties.

3. Aluminum: Aluminum is chosen for its lightweight properties, making it suitable for applications where weight reduction is important. It is commonly used in industries such as automotive and aerospace.

4. Stainless Steel: Stainless steel is used when corrosion resistance is a critical factor. It is commonly employed in environments where the coupling may be exposed to moisture or corrosive substances.

5. Bronze: Bronze can be used in certain applications where self-lubricating properties are desired. It also provides good wear resistance.

6. Synthetic Polymers: Some modern cardan couplings use synthetic polymers or plastics in their construction to reduce weight and provide specific performance characteristics, such as dampening vibrations.

The choice of material depends on factors like the application requirements, operational conditions, torque transmission, operating speed, and environmental factors. Manufacturers select materials that offer the best combination of strength, durability, wear resistance, and corrosion resistance for the specific use case of the cardan coupling.

How do you properly install and maintain a cardan coupling in machinery?

Proper installation and maintenance of a cardan coupling are crucial to ensure its reliable performance and longevity:

- Installation:

- Align the shafts properly before connecting the coupling to minimize initial misalignment.

- Ensure that the universal joints are in phase, meaning their yokes are in the same orientation to prevent uneven torque transmission.

- Follow the manufacturer’s instructions for torque specifications while tightening bolts and fasteners to prevent overloading or loosening during operation.

- Make sure the coupling is properly centered and balanced to avoid vibrations.

- Check for any obstructions or interference that might affect the movement of the coupling.

- Maintenance:

- Regularly inspect the coupling for signs of wear, such as cracks, corrosion, or damaged components.

- Monitor the alignment of the shafts to detect any misalignment that might occur over time.

- Lubricate the universal joints and bearings as recommended by the manufacturer to reduce friction and wear.

- Replace worn or damaged components promptly to prevent further deterioration and potential coupling failure.

- Perform vibration analysis and balancing to ensure the coupling operates smoothly and doesn’t contribute to excessive vibrations in the machinery.

- Regularly check for any signs of overheating, which might indicate inadequate lubrication or other issues.

- Keep the coupling area clean from debris, dirt, and contaminants that could affect its performance.

By following proper installation procedures and conducting regular maintenance checks, you can maximize the efficiency and reliability of a cardan coupling in machinery.

editor by CX 2024-03-02

China best Flexible Stainless Steel Spider Couplings Balancing Machine for Cardan Shafts

Product Description

| Product Name | Cardan Shaft |

| Product Model | SWC-I75A-335+40 |

| Main Material | 35CrMo or 45# Steel |

| Nominal Torque | 500 N.M |

| Normal Length | 335 mm |

| Length Compensation | 40 mm |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance Practices for Ensuring Cardan Coupling Reliability

To ensure the reliability of cardan couplings, the following maintenance practices are crucial:

- Lubrication: Regularly inspect and maintain the lubrication system. Ensure proper lubricant levels and use lubricants recommended by the manufacturer.

- Alignment: Maintain proper alignment between the input and output shafts. Misalignment can lead to premature wear and reduced efficiency.

- Regular Inspections: Perform visual inspections to detect signs of wear, damage, or corrosion. Regular inspections can help identify issues before they become major problems.

- Monitoring: Use sensors and monitoring systems to track the performance of the cardan coupling. Monitor temperature, vibration, and other parameters for anomalies.

- Torque Analysis: Analyze the torque requirements of the machinery system to ensure that the cardan coupling can handle the load without exceeding its limits.

- Periodic Maintenance: Follow the manufacturer’s recommended maintenance schedule. This may include replacing worn components, lubricant changes, and alignment adjustments.

- Record Keeping: Maintain detailed maintenance records, including inspection dates, lubrication schedules, and any repairs performed.

- Training: Ensure that maintenance personnel are trained to properly inspect, maintain, and troubleshoot cardan couplings.

By implementing these maintenance practices, operators can extend the lifespan of cardan couplings, prevent unexpected failures, and optimize the performance of machinery systems.

Handling High Torque and Axial Displacement with Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are designed to transmit torque between two shafts that are not in a straight line. They are versatile components commonly used in various applications, including those requiring high torque and axial displacement.

Handling High Torque: Cardan couplings are capable of handling high levels of torque transmission due to their robust design and construction. The design allows for torque to be transmitted through a series of interconnected components, including the cross-shaped yokes and the bearing assemblies. The use of high-strength materials and precision manufacturing techniques contributes to the coupling’s ability to transmit torque efficiently.

Handling Axial Displacement: While cardan couplings are primarily designed for accommodating angular misalignment, they can also handle a certain degree of axial displacement. Axial displacement refers to the movement of the connected shafts along their axis. However, the axial displacement capacity of a cardan coupling is limited compared to its ability to handle angular misalignment.

It’s important to note that excessive torque or axial displacement beyond the coupling’s design limits can lead to premature wear, increased vibrations, and reduced performance. Manufacturers provide specifications and guidelines for the maximum torque and axial displacement that a specific cardan coupling can handle. Engineers and designers should adhere to these specifications to ensure optimal performance and longevity of the coupling in their applications.

What is a cardan coupling and how is it used in mechanical systems?

A cardan coupling, also known as a universal joint or U-joint coupling, is a mechanical component used to transmit torque between two shafts that are not in alignment but intersect at an angle. It consists of a cross-shaped yoke with two perpendicular shafts connected at its ends, allowing the transmission of rotational motion even when the shafts are at different angles to each other. Cardan couplings are widely used in mechanical systems to transmit torque and motion where angular misalignment is present.

Here’s how a cardan coupling works and how it is used in mechanical systems:

- Angular Misalignment: Cardan couplings are designed to accommodate angular misalignment between shafts. They can transmit torque between shafts that are at an angle to each other, typically up to 45 degrees. This ability to handle misalignment makes them suitable for various applications.

- Components: A cardan coupling consists of a cross-shaped yoke with four arms, two of which are connected to the input and output shafts. The two remaining arms are connected to each other through a bearing, which allows for the rotational motion.

- Transmitting Torque: As one shaft rotates, it imparts angular motion to the yoke. This angular motion is transferred to the other shaft through the bearing, allowing torque to be transmitted even when the shafts are not collinear.

- Application: Cardan couplings are used in various applications, including automotive drivetrains, industrial machinery, agricultural equipment, and even in some aerospace systems. They are often found in places where it’s necessary to transmit torque between non-parallel shafts while allowing for some degree of flexibility.

- Advantages: Cardan couplings are simple in design, relatively compact, and provide a cost-effective solution for transmitting torque in cases of angular misalignment. They are also capable of transmitting high torques while compensating for misalignment.

- Limitations: Cardan couplings have limitations in terms of the angle they can handle, and at extreme angles, they may produce uneven torque output due to their design. They can also introduce some degree of vibration and require periodic maintenance.

In mechanical systems, cardan couplings are used in various applications where the alignment between shafts cannot be maintained, such as in vehicles with independent suspension systems, industrial machinery with non-parallel shafts, and applications where flexibility and torque transmission are required despite angular misalignment.

editor by CX 2024-02-15

Rotary sales made in China – replacement parts – italian pto shafts Lawn Mower for Sale with Ce with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto manufacturing unit in China with 5 various branches. For more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

front push shaft u joint alternative Our rural king pto shaft merchandise pto shaft put in is 2010 mercedes c300 entrance generate shaft substitution popular hub town pto adapter exported honda gx160 pto shaft dimensions to bush hog shaft protect the 2011 dodge charger generate shaft United pto reducer gearbox States, pto shaft brush hog Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The united states, Thailand, Pakistan, Indonesia, a lot more than sixty international locations and regions. The business was certified by ISO9001:2008 Good quality Administration Program. Specification:

- three point linkage

- Graphite casting iron gearbox

- Tractor power necessary: twenty five-55hp

Item Attribute

- Transmission: By sturdy toothed belts.

- Gearbox is made of graphite casting iron. Substance overall performance is greater. Not simple broken.

- The blade axle runs stably at high pace right after dynamic harmony test, with lower sounds.

- The blades have a lot more amount, larger density and higher mowing efficiency.

- Mowing peak can be modified.

- With front protection, it can avoid splashing.

- Y form blades and hammers are optional, to meet the demands of distinct consumer.

- Cat. I universal three-point hitch cardan shaft.

Merchandise Show

Requirements

| Product | EFG–a hundred and five | EFG-1twenty five | EFG-one35 | EFG-150 | EFG-one65 | EFG-180 |

| Dimension(mm) | 1250×855×805 | 1450×810×815 | 1550×810×815 | 1700×810×815 | 1850×810×815 | 2000x810x815 |

| Excess weight(Kg) | 195 KG | 230KG | 250KG | 280KG | 310KG | 340KG |

| Chopping Width | 1050mm | 1250mm | 1350mm | 1500mm | 1650mm | 1800mm |

| PTO Enter Pace | 540r/min | 540r/min | 540r/min | 540r/min | 540r/min | 540r/min |

| Number of hammers | 20 | 24 | 28 | 28 | 32 | 36 |

| Number of Y sharp blades | 40 | forty eight | 56 | fifty six | 64 | 72 |

| Electricity Necessary | twenty five-35HP | thirty-40HP | 30-40HP | 35-45HP | 40-50HP | 40-55HP |

Business Profile

HangZhou EPT Sector & Trade Co., Ltd., is a expert company and exporter of complete established of agriculture equipment and backyard tools. Our company was recognized because 2003 with Hanma Industry Firm.

Our primary merchandise consist of rotovator, flail mower, finishing mower, topper mower, wooden chipper, plow, cultivator, potato harvester/ planter and Japanese tractor elements, and many others. Due to our tremendous EPT quality stHangZhourd and speedy & excellent after-sales support, EPT devices are tremendously well-liked in numerous marketplaces about the entire world, and currently attained to Europe, North The united states, South America, Australia, almost addresses eighty international locations in Entire world.

EPT always believe that we will consider better farming daily life to you by best-quality laser cutting equipment & CNC bending equipment & skilled paint-spraying & robust welding.

Packing & Delivery

Packaging Depth: Iron pallet or wooden cases

Delivery Element: By sea or By air

1. Watertight packing with the EPT export stHangZhourd by 20ft, 40ftcontainer.

Wooden Scenario or Iron Pallet.

two. The total established of machines size are large as typical, so we will use Water-proof materia EPT to pack

all of them. The motor, gear box or other effortlessly broken components, we will put them into box.

Machine videos in YOUTOBE

https://youtu.be/UCDWDR3Pjrg EPT business online video

https://youtu.be/Bc8UzmpHiyU EFD flail mower

https:///look at?v=Bh73zRIYBpc EFDL Side MOWERS

https:///look at?v=O_tVXodWdN8 EFG FLAIL MOWERS

https:///observe?v=ZuWSCmiPows EFGL Facet MOWERS

https:///look at?v=iH6uQiqEyuQ FM Ending MOWERS

https:///watch?v=VLUEyam_5DY TM TOPPER MOWERS

https:///view?v=jphaylxaKUg RT ROTARY TILLERS

https://youtu.be/d3H1-yXUImc AP-ninety POTATO HARVESTER

https://youtu.be/AAkgnV_bY80 LF-PT32 POTATO PLANTER

https:///observe?v=pb76s1cHRgU&feature Wood chipper BRH80

https://youtu.be/66geQQOUTLY wood chipper BX-forty two

FAQ:

Q1. How to buy flail mowers?

Inquiry ———> Quotation ——–>Price reasonable ——->Check with specification —–>Proforma Bill sent ————>Payment created ——-> Making the objects ——->Product shipment ———–> Buyer affirm

Q2.How prolonged is the supply date for flail mowers?

A:In common, we can ship the products within thirty-forty five days following obtaining your payment. Of course, it also is dependent on your amount.

Q3. How can I get to your factory to acquire flail mowers?

A:We are positioned in HangZhou, only 1 hour’s length to ZheJiang or HangZhou. You can fly to ZheJiang /HangZhou/HangZhou Airport , the transportation is really hassle-free

Q4.Do you have inventory for flail mowers?

A:In general, we have some inventory, whilst if you need a bulk buy, we even now require time to create it. Of system, we will inform all detai EPT you ahead of your payment.

Q5: What is actually your principal merchandise?

A: Our products are protected practically all farm machines and Japanese tractors parts, we can meet your any calls for.

Q6. What is your terms of payment?

A: T/T, L/C, Paypal, Western Union

Best China manufacturer & factory Rotary in Quetta Pakistan Tillers Pto Shafts 1 3 8" 6 Spline And Shear Pin Clutch With CE Certificated With high quality best price

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements,a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Local Service Location:

-

Italy

- certificate:

-

CE

- Material:

-

Metal

- StruSlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.cture:

-

W or S

The company was certified by ISO9001:2008 Quality Management System.

- Tube:

-

Triangular, Lemon, Star tube

- Process:

-

Forged

- Design:

-

Customized

- Certificate:

-

CE Certificate

- Package:

-

Iron pallet&wooden carton&standard export packaging

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Packing details:Iron pallet&wooden carton&standard export packaging

- Port

- NINGBO OR SHANGHAI

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and OUR HIGH-END SEGMENT: FINDING THE BEST SOLUTION FOR THE CUSTOMER The high-end segment often requires customized solutions. In these cases, we provide you with in-depth consulting in order to devise a common solution to meet your requirements. Only then do we get down to the actual work.experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Structure | W or S |

| Tube | Triangular, Lemon, Star tube |

| Process | Forged |

| Design | Customized |

| Certificate | CE Certificate |

| Package | Iron pallet&wooden carton&standard export packaging |

Product Display

Product Display

L series aluminium …

PTO Drive Line Gen …

Tie Rod Cylinder H …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

China pto shafts edmonton with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto factory in China with five distinct branches. For far more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

It We are a expert producer of equipment bins, gear pumps, gears, shafts, and other machining components. Launched in 1 0571 , we cover eighteen,000 square meters in area. g37 driveshaft is pto drive shaft cover our axial drive shaft purpose b EPT e90 generate shaft to pto shaft keeps breaking supply pto tractor generator a comer pto areas v EPT tractor pto shaft for sale assortment double cv driveshaft of pto shaft will not lock high quality items at reasonably priced rates, supply the greatest service for buyers satisfied and contribute to our ongoing advancement. We warmly welcome the buddies from all the globe!

Pto China comer pto shaft guard Shafts Coupling Universal Joint Coupling Transmission Part Flexible Coupling with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto manufacturing facility in China with five distinct branches. For more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

ford figo push shaft The weasler pto shaft catalog firm echo srm 225 pto shaft duration was ford 8n pto shaft include certified audi a3 drive shaft by tractor pto shaft ISO9001:2008 pto shaft measurement record Good quality pto shafts nz Management ford 8n pto shaft substitute System. new holland tractor pto shaft Our organization has reliable financial toughness, builds up a technician team contingent with higher high quality, possesses the production assembly line of technicalization in China and perfect program checking on product top quality and runs advertising networks during the place. HangZhou EPT Electronic Technologies Co., Ltd. is located in the gorgeous coastal metropolis of HangZhou. We have been focusing on the R & D, manufacturing and product sales of industrial automation components. At existing, the principal merchandise are diaphragm coupling, plum coupling, cross slider coupling, bellows coupling, etc

Given that its establishment, our firm has been committed to the advancement and innovation of industrial automation. The company adheres to the business spirit of “higher education, pragmatic, arduous and revolutionary”, and is committed to producing outstanding merchandise in factory automation components. Up to now, the firm has imported machining centers, information device equipment, CNC milling devices and CNC chopping and other superior machining products. At presentSample image our items are bought to massive domestic enterprises and exported to Europe, The us, Africa and Southe EPT Asia. And get praise and welcome from clients.

Sample picture

Specification

Delivery

With your get in touch with and guidelines, we will safely deliver your products to any vacation spot.