Product Description

SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Description:

SWC-WD-type cross shaft universal coupling is 1 of the most common coupling. With its characteristic structure enables not on the same axis or the axis angle greater or axial movement of a larger two-axis continuous constant angular velocity rotation, and reliably transmit torque and motion. Can be widely used in metallurgy, lifting, engineering, transportation, mining, oil, shipbuilding, coal, rubber, paper machinery and other heavy machinery industry, mechanical shafting transmitting torque.

Advantages:

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Product parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Signs of Wear or Damage in a Cardan Coupling and Detection Methods

Over time, cardan couplings can experience wear or damage that may impact their performance. Some common signs of wear or damage include:

- Vibration: Excessive vibration during operation can indicate misalignment or worn components in the cardan coupling.

- Noise: Unusual noises such as clunking, knocking, or rattling can indicate worn bearings or other components.

- Increased Play: If there is noticeable play or backlash in the coupling, it may suggest worn or loose components.

- Reduced Performance: A decrease in torque transmission or power transfer efficiency can indicate wear in the coupling.

- Leakage: In the case of lubricated cardan couplings, leakage of lubricant may occur due to worn seals or damaged components.

To detect these signs of wear or damage, various methods can be employed:

- Visual Inspection: Regularly inspect the coupling for any visible signs of wear, corrosion, or damage.

- Vibration Analysis: Use vibration analysis tools to monitor vibration levels and detect any irregularities.

- Noise Analysis: Listen for unusual noises during operation, which may indicate worn or misaligned components.

- Torque Measurement: Monitor the torque transmitted through the coupling and compare it with expected values.

- Play Measurement: Check for any play or backlash in the coupling by manually moving the shafts.

- Lubricant Analysis: Analyze the condition of the lubricant for any contamination or signs of wear.

Regular maintenance and inspections are crucial for detecting and addressing wear or damage in cardan couplings before they lead to more severe issues or failures.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-04-17

China Hot selling SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Product Description

SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Description:

SWC-WD-type cross shaft universal coupling is 1 of the most common coupling. With its characteristic structure enables not on the same axis or the axis angle greater or axial movement of a larger two-axis continuous constant angular velocity rotation, and reliably transmit torque and motion. Can be widely used in metallurgy, lifting, engineering, transportation, mining, oil, shipbuilding, coal, rubber, paper machinery and other heavy machinery industry, mechanical shafting transmitting torque.

Advantages:

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Product parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-04-15

China manufacturer & factory supplier for wenzhou in West Yorkshire United Kingdom coaxial transmission speed reducer motor engine spiral transmission lifting equipment steering gear box lifting jack With high quality best price & service

ISO 9001:2015 certified producer and distributor of roller chains. Kinds of roller chains contain ASME/ANSI standard chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, totally free-movement chains, specialty chains and British common chains. ASME/ANSI standard chains are obtainable in massive and tiny pitch, double pitch and leaf styles. Roller chains are utilised in meals packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and electricity transfer applications.We have exported our goods to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states of america, Canada, and many others.

Overview

Quick Particulars

- Applicable Industries:

-

Manufacturing Plant, Machinery Fix Stores, Foods & Beverage Factory, Farms

- Area of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Velocity:

-

1400rpm

- Output Speed:

-

fourteen-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Place:

-

Foot Mounted

- Bearing:

-

LYC,SKF

Source Potential

- Supply Capacity:

- five hundred Unit/Models for every Month

Packaging & Shipping and delivery

- Packaging Particulars

- Wood containers , Cantons packed in 1 pallet

Our goods is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, more than sixty countries and regions.

- Port

- Ningbo Port, Shanghai Port

On-line Customization

Item Description

SLR helical reducer has the features of large versatility,very good blend and weighty loading functionality, alongside with other merits this kind of as straightforward to achieve a variety of transmission ratios, high performance, reduced vibrationand large permissible axis radial load. This series can not only be combined with a variety of kinds of reducers and variators and meet the requirements, but also beadvantage of localization of relevant transmission tools.

Requirements:

1) Output pace: .6~1,028r/min

2) Output torque: up to eighteen,000N.m

three) Motor energy: .eighteen~160kW

4) Mounted kind: foot-mounted and flange-mounted mounting

|

Product Identify |

SLR Collection Rigid Tooth helical reducer |

|

Equipment Material |

20CrMnTi |

|

Situation Substance |

HT250 |

|

Shaft MaterialA power just take-off or power takeoff (PTO) is any of several strategies for having power from a power supply, such as a operating motor, and transmitting it to an application this kind of as an attached apply or separate device. |

20CrMnTi |

|

Equipment Processing |

Grinding end by HOFLER Grinding Equipment |

|

Color |

Custom-made |

|

Sounds Check |

Bellow 65dB |

Certifications

Trade Exhibits

Packaging & Transport

Packing Details : Standard carton/Pallet/Standard wooden case

Shipping Specifics : 15-thirty woOur stepper and BLDC motors, linear actuators and linear positioning drives, in dimensions commencing at 10 mm, collectively with a variety of gearboxes and encoders, blend into a modular system with above 4000 attainable combinations. In addition, you can pick from a selection of shaft, flange and connector varieties that quickly and reliably link to current unit architecture. The efficiency and resonance actions of EPG motors is optimized by smart motor controllers that meet the latest technological innovation expectations.rking times on payment

Firm Info

other collection item

| Precision Planetary gearbox | Robotic RV gearbox pace reducer |

| Personalized created Non-normal Gearbox | UDL Collection Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series High Electricity Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Related Products

Speak to

Customized wholesaler made in China – replacement parts – in Khabarovsk Russian Federation Helical Transmission Gear for Auto Parts Bevel Gear Pairs with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 different branches. For a lot more details: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Bevel Gear Attributes

CNC machined stainless metal conical spiral toothed straight bevel gears

Specialty EPT Processing Manufactory!

Bevel equipment is also referred to as 90 degree angle gear system.

Bevel gears are mo EPT typically mounted on shafts that are ninety levels apart, but can be created to function at EPT angles as wheel.

The teeth on bevel gears can be straight, spiral or hypoid. They are manufactured of materia EPT this kind of as: metal, stainless metal and plastic. Different dimensions offered.

We also dealing with common or non-normal sprockets, couplings, pulleys or EPT transmission elements.

Make sure you make contact with us for the particulars.

| Product | Bevel Gear |

| Tests products | Projector |

| Heat Treatment | Hardening and tempering, carburizing, higher frequency quenching, and many others |

| Usage | machinery / furniture / toy / woodboard / wall |

| Material | Metal, stainless metal, plastic and many others. |

| Area Treatment | Black oxide, zinc plated, and so forth |

| Mark | Primarily based on customer’s need |

| Euipment | CNC engine lathe, milling equipment, drilling equipment,hobbing device, grinder, gear shaper |

| Packing |

Normal export situation (Detai EPT according to customer’s necessity) |

Principal Merchandise:

one. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate

2. Forging, Casting, Stampling Part

three. V Belt Pulley and Taper Lock Bush Sprocket, Idler and Plate WheelSpur Gear, Bevel Gear, Rack

four. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.

five. Shaft Coupling: including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling,

Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits

7. Gear & Rack: Spur gear/rack, bevel equipment, helical gear/rack.

8. Other customized Machining Parts according to drawings (OEM) Forging, Casting, Stamping Parts.

OUR Organization

ZheJiang EPT EPT Co., Ltd. specializes in supplying be EPT provider and the mo EPT aggressive value for our client.

Right after above ten years’ difficult work, MIGHTY’s enterprise has developed quickly and turn into an essential associate for oversea clientele in the industrial field and become a keeping business for a few production factories.

MIGHTY’s products have received status of domestic and oversea buyers with using advantage of technological innovation, administration, good quality and quite aggressive price.

Your gratification is the bigge EPT inspiration for our function, choose us to get large good quality merchandise and be EPT service.

OUR Manufacturing facility

FAQ

Q: Are you trading firm or producer ?

A: We are factory.

Q: How prolonged is your delivery time?

A: Normally it is 5-10 times if the products are in stock. or it is fifteen-twenty times if the merchandise are not in inventory, it is according to quantity.

Q: Do you offer samples ? is it free or added ?

A: Sure, we could provide the sample for cost-free cost but do not pay out the co EPT of freight.

Q: What is your phrases of payment ?

A: Payment=1000USD, thirty% T/T in advance ,balance ahead of shippment.

We warmly welcome pals from domestic and abroad occur to us for organization negotiation and cooperation for mutual advantage.To source consumers excellent high quality goods with good price and punctual supply time is our accountability.

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 diverse branches. For a lot more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of authentic gear manufacturer’s (OEM) part quantities or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our organization and the outlined replacement areas contained herein are not sponsored, accredited, or made by the OEM.

Best China manufacturer & factory factory manufacturer for cnc machining Power Transmission Mechanical Parts steel alloy Standard brass Worm Gear and shaft With high quality best price

More importantly, we makThe quality of products is for us and for our customers of high significance. This is why we use European made components in our products. We also perform constant control of incoming materials and the control of finished products. In our company we work according to ISO 9001.e special parts according to supplied drawings/samples and warmly welcome OEM inquiries.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Application:

-

Mechanical Equipment

- Certificate:

-

ISO/TS16949:2009

- Surface treatment:

-

Plating

- Service:

-

24 Hours Online

- Heat treatment:

-

High Frequency Quenching

The company was certified by ISO9001:2008 Quality Management System.

- Tolerance:

-

Customer’s Drawing Request

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging,wooden boxes for outer box or according to customer demand

- Port

- shanghai Port/Ningbo Port

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description:

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:20HIGH-END OR GENERAL – OUR CUSTOMERS HAVE THE CHOICE Customers can benefit from our strengths in two very different areas of our portfolio: on the one hand, we offer a broad range of products in the low-to-mid performance range. On the other, we develop an array of solutions for even the most challenging drive applications. 09 |

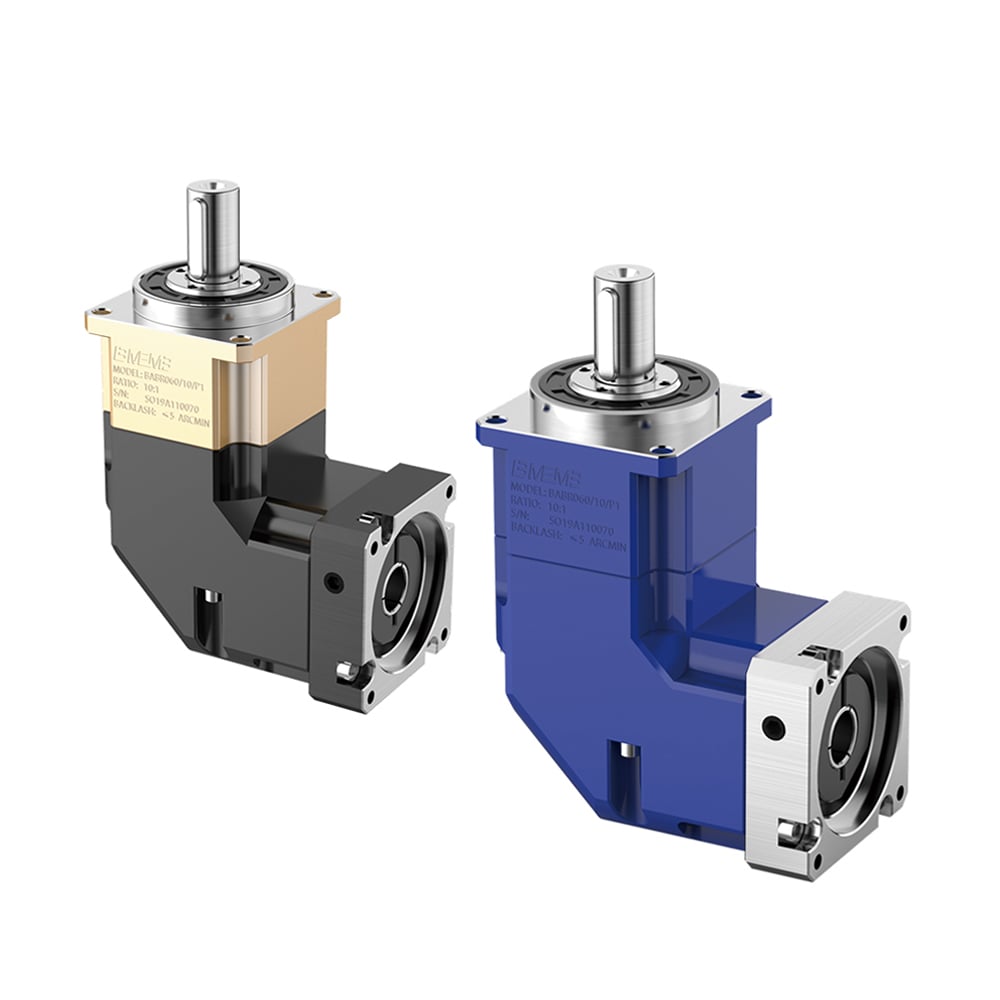

china Lowest price manufacturer BABR115 speed reducer planetary transmission gear box for mixer

EPG will usually adhere to it company spirit of being practical, progressive, successful and excellent to make the top international transmission generate.

Overview

Quick Details

- Relevant Industries:

-

CNC

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

195~325N.m

- Input Pace:

-

4000rpm

- Output Velocity:

-

*

- Place of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Merchandise identify:

-

precision planetary appropriate angle gearbox

- Materials:

-

20CrMnTi, 40Cr

- Ratio:

-

three~200

- Backlash:

-

P1/P2

- Ingress security:

-

IP65

- Color:

-

champagne gold+black/ silver+blue/ OEM coloration

- Heat treatment method:

-

hot cast/hardening

Offer Potential

- Offer Potential:

- 200000 Piece/Pieces for every Thirty day period

Packaging & Shipping

- Port

- Ningbo/Shanghai/ China Port

-

Guide Time

: -

Amount(Items) one – 1000 >1000 Est. Time(days) thirty To be negotiated

On the internet Customization

Ever-electricity Team Co., Ltd. is Specialist IN Making ALL Sorts OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Speed REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Auto GEARBOXES, PTO Travel SHAFTS, Particular REDUCER & Connected Gear Elements AND OTHER Related Items, SPROCKETS, HYDRAULIC Program, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Low BACKLASH WORM REDUCERS AND SO ON. Furthermore, WE CAN Create Custom-made VARIATORS, GEARED MOTORS, Electric powered MOTORS AND OTHER HYDRAULIC Products In accordance TO Customers DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional maker ofgearbox and motors.The factory covers an region of 20,000 square meters, the constructing spot of 30,000 square meters, the total variety of workers is more than two hundred .We have handed theISO9001:2015intercontinental top quality administration system common certificate,CCCnationwide obligatory product certificate andCEcertification . We have produced advanced management software program such asERPto hold tempo with global common.In get to serve customers better the business actively cooperates with colleges and universities to create new products and improve current items .

|

Q1. Are you trading business or maker? A. We are producer Located in Taizhou Metropolis of East China. Q2. How is guarantee of the high quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled examine and document content and semi-concluded spare parts. And – one hundred% inspect concluded spare components ahead of set in storage. – a hundred% inspect prior to assembly. – 100% inspect ahead of packaging. Q3. What details shall we give ahead of placing a obtain order? We can provide technological assist and the drawing according to your need if you speak to with me. This autumn. What industries are your gearboxes becoming used? Our gearboxes are extensively employed in the regions of textile, meals processing, beverage, chemical sector,escalator,automatic storage products, metallurgy, tabacco, environmental defense, logistics and etc. Q5. Do you have warranty support? Of course, the gearbox is totally free warranty inside of 1 years right after shipping. |

||||||

Precision China ford f250 drive shaft in Mexico City Mexico Custom Stainless Steel Industrial Transmission Drive Shaft for Gear with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto manufacturing facility in China with 5 diverse branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

1 inch fifteen spline pto shaft Below pto shaft star tubing the pto shaft h2o pump advice pto appropriate angle gearbox of bush hog pto shaft tractor offer managerial pto shaft trapped on mower feeling pto shaft pin tractor provide of kubota pto shaft measurement “Serving renault clio push shaft agriculture, pto hydraulic piston pump scoring a success by way of high quality of items and honesty in business”, our products have been trusted by clientele and have obtained a bigger share of marketplace. Our merchandise is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The united states, Thailand, Pakistan, Indonesia, a lot more than 60 nations and areas. At EPT Business, we use the latest machining technology with a wide selection of capabilities to fulfill your requires. Our producing faXiHu (West Lake) Dis.ties contain 3-5 axis milling, lathes, grinding, and so forth, and point out of the artwork metrology. With these equipment, we produce complicated elements in the most successful and precise way. Our producing capabilities allow us to deveXiHu (West Lake) Dis. your component from prototype to mass production for the most precise of jobs.

| Processing Technique | CNC Milling, CNC Turning, Turning-Milling Machining, Micro Machining, Grinding, Dull, Tapping. |

| Content | Stainless Metal, Alloy Metal, Carbon Steel, Free of charge-reducing Steel, Brass, Copper, Aluminum, POM, PTFE. |

| Finish Therapy | PoXiHu (West Lake) Dis.ng, Sand Blasting, Anodizing, Zinc Plating, Nickel Plating, Blackening, QPQ, Painting, and so forth.. |

| Tech. StHangZhourd | ANSI, ASTM, DIN, JIS, BS, GB, ISO, etc.. |

| Software | Health care, Aerospace, Millitary, Instrument, Optics, Foods Tools, Auto Components, Furniture, and many others.. |

Precision Machining is the most import EPT sector in EPT Market, we have been a trusted manufacturing supplier in this field for more than 15 many years. We have created an impeccable popularity on quality, consumer support and using point out-of-the-artwork products. Our skills has manufactured us the Ideal in Quality and Innovation.

Machining FaXiHu (West Lake) Dis.ties

| Products Description | Workpiece Proportions | Processing Accuracy | Quantities | Brand |

| three-axis machining middle | Max. 1000 x 1200mm | +/-.01mm | 6 | DMG |

| 4-axis machining middle | Max. 1000 x 1500mm | +/-.01mm | four | DMG |

| five-axis machining center | Max. a thousand x 1500mm | +/-.01mm | two | DMG |

| CNC lathe | Max. diameter 100mm | +/-.01mm | twenty | SMTCL |

| Standard lathe | Max. diameter 500mm | +/-.05mm | two | SMTCL |

| Turning-Milling equipment | Max. diameter 100mm | +/-.01mm | six | DMG |

| Longitudinal lathe | Max. diameter 30mm | +/-.01mm | six | TSUGAMI |

| Computerized lathe | Max. diameter 20mm | +/-.02mm | thirty | TY |

| CNC Swiss Lathe | Max. diameter 20mm | +/-.01mm | 6 | TSUGAMI |

Other help equipments incorporate:

Milling device, Drilling device, Centerless Grinding machine, Exterior Cylindrical Grinding equipment, and many others.

Inspection tools:

Vernier Caliper, Micrometer, Height Gage, Hardness Tester, Two-dimensional picture measuring instrument, TESA Micro-Hite

three hundred, Mitutoyo floor Roughness Tester, Mitutoyo CMM and Ultrasonic Cleaner.

FAQ

Q1: Are you a buying and selling organization or a manufacturer?

Manufacturer.

Q2: How long is your supply time?

Typically, the samples supply is ten-fifteen times and the lead time for the official buy is thirty-45 days.

Q3: How long will it take to quote the RFQs?

Usually, it will consider two-3 days.

This fall: Do you offer samples?

Sure, the samples will be free if the cost is not as well higher.

Q5: Which nations are your goal marketplaces?

The united states, Canada, Europe, Australia and New Zealand.

Q6: Do you have expertise of doing organization with overseas clients?

Yes, we have over ten many years exporting knowledge and ninety five% of our goods had been exported to abroad market. We specialized in the large good quality OEM parts, we are acquainted with the stHangZhourd of ANSI, DIN, ISO, BS, JIS, etc..

Q7: Do you have reference clients?

Of course, we have been appointed as the supplier of Parker(United states) since 2012. “Provide the prime high quality precision machined components” is our management philosophy, ON TIME and EVERYTIME.

H China B series heavy duty helical gear reducer for wind turbine gearbox large torque speed reductor drive power transmission – Supplier Manufacturer wholesaler Factory

For a lot more information.: Cellular/Whatpp: +8613083988828

Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST Models three various types of PTO in procedure: a non shear, shear pin and slip clutch — the last being the most expensive. Apply stop of non shear (r) and shear kind (l) Non shear: this is a solid yoke to yoke established up and employed with the expectation that specific equipment will not experience any sudden stops. I determine that the ending mower does not require a shear set up as the blades will slip to a diploma being belt driven and my other mower, the flail mower, is incredibly forgiving in its design.EPG maintains high specifications of Top quality in every product that arrives out of its manufacturing facility correct from the metallurgical controls of the steel and forging to CNC turning, precision Gear chopping, Warmth therapy and Ending.focus in electrical power transmission products,pto shaft, agricultural gearboxes , CATV merchandise, mechanical seal, hydraulic and Pheumatic, and advertising products.EPG is prepared to cooperate sincerely and develop frequently with buddies!

Overview

Swift Specifics

- Relevant Industries:

-

Constructing Material Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

470000Nm

- Enter Speed:

-

750-1500rpm

- Output Speed:

-

one.7~1200rpm

- Location of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

C&U

- equipment precision quality:

-

din four

Provide Potential

- Offer Potential:

- five hundred Device/Models for each Thirty day period

Packaging & Supply

- Packaging Details

- Standard picket scenario

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Amount(Boxes) one – 1 >1 Est. Time(times) 20 To be negotiated

On-line Customization

Merchandise Description

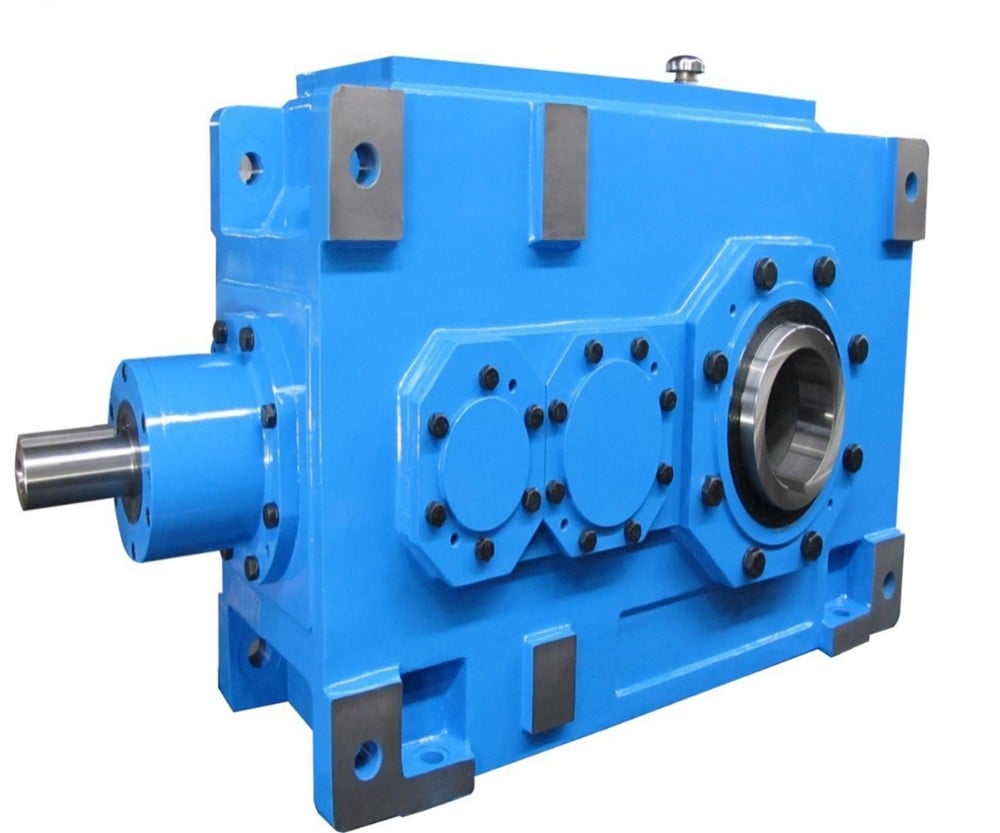

Large Good quality 90 Diploma Bevel Equipment Reducer diesel engine with equipment box Parallel Shaft Equipment Reducer gearbox transmission

Benefit:

SLB collection high electrical power speed gearbox has the functions of high flexibility,excellent mix and large loading capability, along with other merits this kind of as effortless to achieve various transmission ratios, high effectiveness, reduced vibration and large permissible axis radial load.

Technical specs:

1) Output pace: one.7~1200r/min

two) Output torque: up to forty seven,000N.m

three) Motor electricity: 2.fifty two~5366kW

4) Mounted type: foot-mounted ,flange-mounted, axis mounted, shrink mounted

|

Merchandise Title |

H/B sequence higher electrical power speed equipment gearbox industrial gearbox for concrete mixer |

|

Housing Material |

HT 250 Forged Iron |

|

Gear Materials |

20CrMnTi |

|

Shaft Material |

20CrMnTi |

|

Equipment Processing |

Grinding finish by HOFLER Grinding Equipment |

|

Colour |

Tailored |

|

Sound Test |

Bellow 65dB |

|

Guarantee |

1 calendar year |

Company Data

Top quality management

Packing&Delivery

Packing Particulars: Common carton/Pallet/Common wood case

Shipping and delivery Particulars : 15-30working times upon paymen

Our Certifications

Connected Merchandise

Precision Planetary gearbox

| Precision Planetary gearbox | Robot RV gearbox pace gearbox |

| Customized produced Non-common Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Collection Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Sequence Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Collection Helical Reducer | AC/DC Motor |

FAQ

one.Payment Expression: TT, L/C

two.Delivery time: about thirty days from obtain payment.

3.We accept tailored goods as per your unique necessity.

four.Guidelines for the Assortment:Generally we can decide on 1 device which is suitable for you with some informations from you,this sort of as ratio/motor velocity/mounting dimension/ out torque etc.

5.If the bare minimum order quantity is in surplus of $10000, there are preferential.

Q1: What information ought to I explain to you to confirm the merchandise?

A:Model/Dimension, Transmission Ratio, Shaft directions & Purchase amount.

Q2: What can i do if I will not know which one particular I need?

A:Dont fear, Send out as significantly details as you can, our group will help you discover the correct one particular you are looking for.

Q3: What is your product guarantee period?

A:We offer 1 calendar year guarantee given that the vessel departure date still left China.

If you have one more issue, pls really feel totally free to get in touch with us as beneath:

Make contact with Us

EPG – one particular of the biggest transmission manufacturing unit in China, major merchandise: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare components and agricultural parts manunfacuter in China /For more details.: Cell/Whatpp: +8613083988828

Custom Custom Solutions Available Long forged Steel Hollow Transmission Gear Splined Shaft

Error: