Introducing Cardan Coupling for Sewing Machines

Keyword Content:

- High-quality Cardan coupling

- Specifically designed for sewing machines

- Ensures smooth and efficient power transmission

- Durable and long-lasting

- Easy to install and maintain

- Optimal performance for sewing operations

What is Cardan Shaft Coupling?

1. Structure:

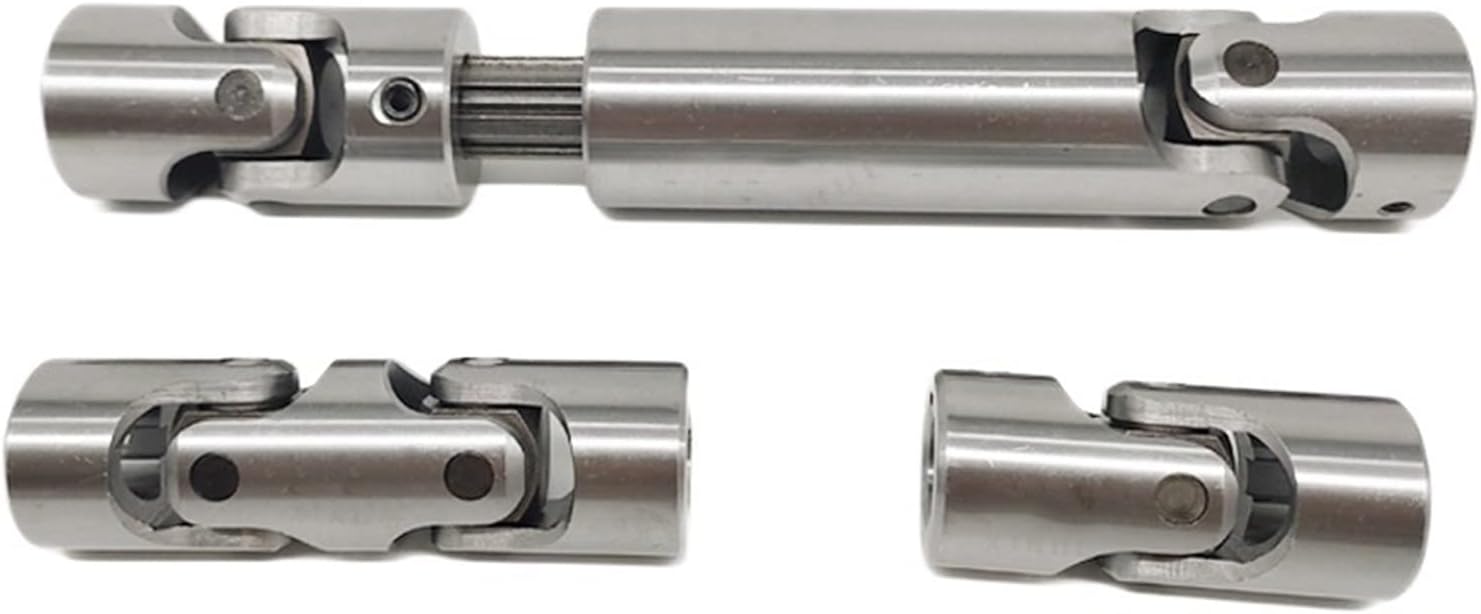

A Cardan shaft coupling is a mechanical device that transmits torque between two shafts that are not in line. It consists of two universal joints connected by a shaft. This design allows for flexibility and compensates for misalignment.

2. Function:

The primary function of a Cardan shaft coupling is to transmit power smoothly and efficiently between shafts, even when they are at different angles or positions. This ensures that the sewing machine operates effectively and without any disruptions.

3. Benefits:

Using a Cardan shaft coupling in sewing machines ensures durability and longevity due to its robust design. It also requires minimal maintenance, making it a cost-effective option for businesses.

4. Installation:

Installing a Cardan shaft coupling in a sewing machine is straightforward and can be done quickly. This means minimal downtime during the installation process, allowing for seamless operations.

5. Maintenance:

Maintaining a Cardan shaft coupling for sewing machines is simple and does not require frequent adjustments. This reduces the overall maintenance costs and ensures consistent performance over time.

6. Performance:

A Cardan shaft coupling optimizes the performance of sewing machines by providing smooth power transmission, resulting in precise stitching and efficient operation.

What is the Purpose of a Cardan Shaft?

1. Power Transmission:

A Cardan shaft is essential for transmitting power from the motor to the sewing machine components, ensuring that the machine operates effectively.

2. Flexibility:

The flexibility of a Cardan shaft allows for misalignment between the motor and the sewing machine, preventing any damage or disruption to the operation.

3. Smooth Operation:

By maintaining a constant speed and power transfer, a Cardan shaft ensures that the sewing machine operates smoothly and efficiently.

4. Durability:

Cardan shafts are known for their durability and ability to withstand high levels of torque, making them ideal for heavy-duty sewing operations.

5. Efficiency:

Overall, the purpose of a Cardan shaft is to enhance the efficiency and performance of sewing machines, providing reliable power transmission for consistent results.

What is the Purpose of a Double Cardan Joint?

1. Increased Flexibility:

A double Cardan joint provides even greater flexibility and compensates for more significant misalignments between shafts in sewing machines.

2. Improved Torque Transmission:

By having two universal joints, a double Cardan joint can transmit torque more efficiently, enhancing the power transfer in sewing operations.

3. Reduced Vibrations:

The design of a double Cardan joint helps to reduce vibrations in sewing machines, resulting in smoother operation and less wear and tear on components.

4. Enhanced Durability:

With the added strength and stability of a double Cardan joint, sewing machines can withstand higher loads and prolonged use without compromising performance.

5. Optimal Performance:

Overall, the purpose of a double Cardan joint is to optimize the performance of sewing machines by providing superior flexibility and torque transmission for reliable operation.

How to Choose the Appropriate Cardan Coupling

1. Consider the Application:

When choosing a Cardan coupling for sewing machines, consider the specific requirements of the application, such as the power and torque transmission needs.

2. Evaluate Shaft Misalignment:

Determine the degree of misalignment between the motor and sewing machine shafts to select a Cardan coupling that can compensate effectively.

3. Assess Durability:

Look for a Cardan coupling that is durable and can withstand the demands of continuous sewing operations without frequent maintenance.

4. Check for Easy Installation:

Choose a Cardan coupling that is easy to install and does not require extensive downtime during the setup process.

5. Opt for Optimal Performance:

Select a Cardan coupling that guarantees optimal performance, ensuring smooth power transmission and efficient sewing machine operation.

What is the Difference Between a Disc and a Cardan Coupling?

1. Structure:

A disc coupling consists of two shaft hubs connected by a flexible disc, while a Cardan coupling has two universal joints connected by a shaft.

2. Flexibility:

Disc couplings offer limited flexibility compared to Cardan couplings, which can compensate for greater misalignment between shafts.

3. Torque Transmission:

Cardan couplings are more efficient in transmitting torque between shafts, making them ideal for heavy-duty sewing operations compared to disc couplings.

4. Maintenance:

Disc couplings require more frequent maintenance compared to Cardan couplings, which are known for their durability and minimal maintenance needs.

5. Application:

While disc couplings are suitable for certain applications, Cardan couplings are preferred for sewing machines due to their ability to provide smooth and reliable power transmission.

About HZPT

Our company, HZPT, established in 2006, specializes in designing, developing, and producing couplings for various industries, including sewing machines. With 16 years of experience, we offer high-quality products with CE and TUV certificates.

We prioritize customer satisfaction and provide 24-hour service, ensuring that our customers receive the best products and support. Our OEM and ODM capabilities allow us to customize products according to specific requirements.

Choose HZPT for the best service, highest product quality, and competitive prices. Join our list of satisfied customers in Europe and the United States for a successful business partnership.