Product Description

SWZ BF Type Cardan Shaft(JB/T3242-1993)

Cardan shaft is widely used in rolling mill, punch, straightener, crusher, ship drive, paper making equipment, common machinery, water pump equipment, test bench, and other mechanical applications.

Advantage:

1. Low life-cycle costs and long service life;

2. Increase productivity;

3. Professional and innovative solutions;

4. Reduce carbon dioxide emissions, and environmental protection;

5. High torque capacity even at large deflection angles;

6. Easy to move and run smoothly;

·Mark example:

Tactical diameter D=260mm,Installation length(L)=1650mm,BF type cardan shaft;

SWZ260BF×1650 Coupling JB/T3242-93

·SWZ BF Cardan Shaft Basic Parameter And Main Dimension(JB/T3242-1993)

| Type | Tactical diameter D mm |

Nominal torque Tn kN·m |

Fatique torque Tf kN·m |

Axis angle β (°) |

Stretch length S mm |

Dimension(mm) | Rotary inertia kg·m2 |

Mass kg |

|||||||||||

| Lmin | Lm | D1 |

D2 H7 |

D3 | k | t | b h9 |

h | n-d | Lmin | Increase 100mm |

Lmin | Increase 100mm |

||||||

| SWZ160BF | 160 | 18 | 9 | ≤10 | 75 | 980 | 120 | 138 | 95 | 114 | 15 | 5 | 20 | 6 | 8-13 | 0.244 | 0.008 | 96 | 3.02 |

| SWZ190BF | 190 | 31.5 | 16 | ≤10 | 80 | 1090 | 135 | 165 | 115 | 133 | 17 | 5 | 25 | 7 | 8-15 | 0.539 | 0.015 | 150 | 4.11 |

| SWZ220BF | 220 | 45 | 22 | ≤10 | 100 | 1260 | 155 | 190 | 130 | 159 | 20 | 6 | 32 | 9 | 8-17 | 1.151 | 0.031 | 238 | 5.96 |

| SWZ260BF | 260 | 80 | 40 | ≤10 | 115 | 1420 | 180 | 228 | 155 | 194 | 25 | 6 | 40 | 12.5 | 8-19 | 2.672 | 0.061 | 388 | 7.82 |

| SWZ300BF | 300 | 125 | 63 | ≤10 | 120 | 1600 | 215 | 260 | 180 | 219 | 30 | 7 | 40 | 15 | 10-23 | 5.312 | 0.095 | 574 | 9.37 |

| SWZ350BF | 350 | 200 | 100 | ≤10 | 130 | 1760 | 235 | 310 | 210 | 273 | 35 | 8 | 50 | 16 | 10-23 | 11.649 | 0.216 | 908 | 13.62 |

| SWZ400BF | 400 | 280 | 140 | ≤10 | 145 | 2040 | 270 | 358 | 240 | 299 | 40 | 8 | 70 | 18 | 10-25 | 21.870 | 0.347 | 1329 | 18.72 |

| SWZ425BF | 425 | 355 | 180 | ≤10 | 145 | 2150 | 295 | 376 | 255 | 325 | 42 | 10 | 80 | 20 | 16-28 | 30.548 | 0.432 | 1615 | 19.18 |

| SWZ450BF | 450 | 450 | 224 | ≤10 | 185 | 2300 | 300 | 400 | 270 | 351 | 44 | 10 | 80 | 20 | 16-28 | 41.310 | 0.586 | 1959 | 22.31 |

| SWZ500BF | 500 | 600 | 315 | ≤10 | 200 | 2600 | 340 | 445 | 300 | 377 | 47 | 12 | 90 | 22.5 | 16-31 | 68.419 | 0.854 | 2658 | 28.76 |

| SWZ550BF | 550 | 800 | 400 | ≤10 | 210 | 2670 | 355 | 492 | 320 | 426 | 50 | 12 | 100 | 22.5 | 16-31 | 106.80 | 1.272 | 3384 | 32.87 |

·Note:1.Tf-Torque allowed by fatigue strength under varible load

2.Lmin-Minimum length after shortening

3.L-Installation length as required

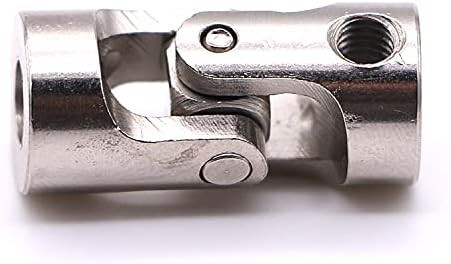

♦Product Show

♦Other Products List

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Company

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

Welcome to customize products from our factory and please provide your design drawings or contact us if you need other requirements.

♦Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you trading company or manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 3:How long is your delivery time?

Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples ? Is it free or extra ?

Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 month under normal circumstance.

Q 6: What is the MOQ?

A:Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling ?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Phasing in Cardan Couplings and Its Impact on Performance

The concept of phasing in cardan couplings refers to the alignment of the universal joints’ yokes or flanges on the input and output shafts. Proper phasing is essential to minimize angular misalignment and maintain smooth rotational motion. When the yokes of the universal joints are not aligned correctly, it can result in uneven torque transmission, increased wear, and vibrations.

Phasing affects the performance of cardan couplings in several ways:

- Uniform Torque Transmission: Proper phasing ensures that torque is evenly distributed between the input and output shafts, reducing the risk of overloading individual universal joints.

- Reduced Vibrations: Correctly phased universal joints minimize angular misalignment, which helps reduce vibrations and noise in the machinery system.

- Extended Lifespan: Improved phasing leads to reduced wear and stress on the universal joint components, extending the overall lifespan of the coupling.

- Efficient Power Transmission: Proper phasing contributes to efficient power transmission by minimizing energy losses due to misalignment.

To achieve proper phasing, manufacturers often provide guidelines or marks on the coupling components to ensure accurate alignment. It’s essential to follow these guidelines during installation and any maintenance or adjustments to maintain optimal performance and reliability of the cardan coupling.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-03-08

China Custom Telescopic Flange Long Cardan Shaft Coupling (SWP-E)

Product Description

Telescopic flange long cardan shaft Coupling(SWP-E)

Cardan shaft is widely used in rolling mill, punch, straightener, crusher, ship drive, paper making equipment, common machinery, water pump equipment, test bench, and other mechanical applications.

Advantage:

1. Low life-cycle costs and long service life;

2. Increase productivity;

3. Professional and innovative solutions;

4. Reduce carbon dioxide emissions, and environmental protection;

5. High torque capacity even at large deflection angles;

6. Easy to move and run smoothly;

Product Description

| Model | D mm |

Tn KN·m |

Tf KN·m |

β | S mm |

mm | ||||||||

| D1 | D2 | D3 | E | E1 | b×h | h1 | L1 | n-d | ||||||

| SWP160E | 160 | 16 | 8 | ≤10 | 50 | 140 | 95 | 114 | 15 | 4 | 20×12 | 6 | 85 | 6-13 |

| SWP180E | 180 | 20 | 10 | ≤10 | 60 | 155 | 105 | 121 | 15 | 4 | 24×14 | 7 | 95 | 6-15 |

| SWP200E | 200 | 31.5 | 16 | ≤10 | 70 | 175 | 125 | 127 | 17 | 5 | 28×16 | 8 | 110 | 8-15 |

| SWP225E | 225 | 40 | 20 | ≤10 | 76 | 196 | 135 | 152 | 20 | 5 | 32×18 | 9 | 130 | 8-17 |

| SWP250E | 250 | 63 | 31.5 | ≤10 | 80 | 218 | 150 | 168 | 25 | 5 | 40×25 | 12.5 | 135 | 8-19 |

| SWP285E | 285 | 90 | 45 | ≤10 | 100 | 245 | 170 | 194 | 27 | 7 | 40×30 | 15 | 150 | 8-12 |

| SWP315E | 315 | 140 | 63 | ≤10 | 110 | 280 | 185 | 219 | 32 | 7 | 40×30 | 15 | 170 | 10-23 |

| SWP350E | 350 | 180 | 90 | ≤10 | 120 | 310 | 210 | 245 | 35 | 8 | 50×32 | 16 | 185 | 10-23 |

| SWP390E | 390 | 250 | 112 | ≤10 | 120 | 345 | 235 | 273 | 40 | 8 | 70×36 | 18 | 205 | 10-25 |

| SWP435E | 435 | 355 | 160 | ≤10 | 150 | 385 | 255 | 299 | 42 | 10 | 80×40 | 20 | 235 | 16-28 |

| SWP480E | 480 | 450 | 224 | ≤10 | 170 | 425 | 275 | 351 | 47 | 12 | 90×45 | 22.5 | 265 | 16-31 |

| SWP550E | 550 | 710 | 315 | ≤10 | 190 | 492 | 320 | 402 | 50 | 12 | 100×45 | 22.5 | 290 | 16-31 |

| SWP660E | 600 | 1000 | 500 | ≤10 | 210 | 544 | 380 | 450 | 55 | 15 | 90×55 | 27.5 | 360 | 22-34 |

| SWP640E | 640 | 1250 | 630 | ≤10 | 230 | 575 | 385 | 480 | 60 | 15 | 100×60 | 30 | 385 | 18-38 |

Detailed Photos

Company Profile

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding and other professionals.

Advanced and reasonable process, complete detection means. We company actively introduce foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

After Sales Service

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

FAQ

Q 1: Are you trading company or manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 3:How long is your delivery time?

Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples ? Is it free or extra ?

Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 month under normal circumstance.

Q 6: What is the MOQ?

A:Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling ?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Diagnosing and Troubleshooting Cardan Coupling Issues

Diagnosing and troubleshooting issues related to cardan couplings in machinery systems involves a systematic approach:

- Visual Inspection: Examine the cardan coupling for signs of wear, damage, misalignment, or corrosion. Look for any unusual noises or vibrations.

- Check Lubrication: Inspect the lubrication system and ensure proper lubricant levels. Inadequate lubrication can lead to premature wear.

- Monitor Performance: Use sensors and monitoring systems to track the performance of the cardan coupling in real-time. Analyze data for anomalies.

- Measure Alignment: Check for proper alignment between the input and output shafts. Misalignment can lead to increased wear and reduced efficiency.

- Check for Unusual Noises: Listen for any unusual noises during operation, such as grinding, squeaking, or knocking sounds.

- Inspect Components: Examine the individual components of the cardan coupling, including the universal joints and shafts, for signs of wear or damage.

- Perform Load Analysis: Evaluate the operating conditions and loads to ensure they are within the specified limits of the cardan coupling.

- Review Maintenance Records: Refer to maintenance records to ensure that the cardan coupling has been properly maintained and serviced.

- Consult Manufacturer Guidelines: Follow the manufacturer’s guidelines for troubleshooting and diagnostics specific to the cardan coupling model.

By following these steps, operators and maintenance personnel can effectively diagnose and troubleshoot cardan coupling issues, ensuring the reliable and efficient operation of machinery systems.

Handling High Torque and Axial Displacement with Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are designed to transmit torque between two shafts that are not in a straight line. They are versatile components commonly used in various applications, including those requiring high torque and axial displacement.

Handling High Torque: Cardan couplings are capable of handling high levels of torque transmission due to their robust design and construction. The design allows for torque to be transmitted through a series of interconnected components, including the cross-shaped yokes and the bearing assemblies. The use of high-strength materials and precision manufacturing techniques contributes to the coupling’s ability to transmit torque efficiently.

Handling Axial Displacement: While cardan couplings are primarily designed for accommodating angular misalignment, they can also handle a certain degree of axial displacement. Axial displacement refers to the movement of the connected shafts along their axis. However, the axial displacement capacity of a cardan coupling is limited compared to its ability to handle angular misalignment.

It’s important to note that excessive torque or axial displacement beyond the coupling’s design limits can lead to premature wear, increased vibrations, and reduced performance. Manufacturers provide specifications and guidelines for the maximum torque and axial displacement that a specific cardan coupling can handle. Engineers and designers should adhere to these specifications to ensure optimal performance and longevity of the coupling in their applications.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2024-03-05

China Custom OEM Flexible Cardan Shaft Coupling

Product Description

Telescopic flange long cardan shaft Coupling(SWP-E)

Cardan shaft is widely used in rolling mill, punch, straightener, crusher, ship drive, paper making equipment, common machinery, water pump equipment, test bench, and other mechanical applications.

Advantage:

1. Low life-cycle costs and long service life;

2. Increase productivity;

3. Professional and innovative solutions;

4. Reduce carbon dioxide emissions, and environmental protection;

5. High torque capacity even at large deflection angles;

6. Easy to move and run smoothly;

| Model | D mm |

Tn KN·m |

Tf KN·m |

β |

S mm |

mm | ||||||||

| D1 | D2 | D3 | E | E1 | b×h | h1 | L1 | n-d | ||||||

| SWP160E |

160 | 16 | 8 | ≤10 | 50 | 140 | 95 | 114 | 15 | 4 | 20×12 | 6 | 85 | 6-13 |

| SWP180E |

180 | 20 | 10 | ≤10 | 60 | 155 | 105 | 121 | 15 | 4 | 24×14 | 7 | 95 | 6-15 |

| SWP200E |

200 | 31.5 | 16 | ≤10 | 70 | 175 | 125 | 127 | 17 | 5 | 28×16 | 8 | 110 | 8-15 |

| SWP225E |

225 | 40 | 20 | ≤10 | 76 | 196 | 135 | 152 | 20 | 5 | 32×18 | 9 | 130 | 8-17 |

| SWP250E |

250 | 63 | 31.5 | ≤10 | 80 | 218 | 150 | 168 | 25 | 5 | 40×25 | 12.5 | 135 | 8-19 |

| SWP285E |

285 | 90 | 45 | ≤10 | 100 | 245 | 170 | 194 | 27 | 7 | 40×30 | 15 | 150 | 8-12 |

| SWP315E |

315 | 140 | 63 | ≤10 | 110 | 280 | 185 | 219 | 32 | 7 | 40×30 | 15 | 170 | 10-23 |

| SWP350E |

350 | 180 | 90 | ≤10 | 120 | 310 | 210 | 245 | 35 | 8 | 50×32 | 16 | 185 | 10-23 |

| SWP390E |

390 | 250 | 112 | ≤10 | 120 | 345 | 235 | 273 | 40 | 8 | 70×36 | 18 | 205 | 10-25 |

| SWP435E |

435 | 355 | 160 | ≤10 | 150 | 385 | 255 | 299 | 42 | 10 | 80×40 | 20 | 235 | 16-28 |

| SWP480E | 480 | 450 | 224 | ≤10 | 170 | 425 | 275 | 351 | 47 | 12 | 90×45 | 22.5 | 265 | 16-31 |

| SWP550E |

550 | 710 | 315 | ≤10 | 190 | 492 | 320 | 402 | 50 | 12 | 100×45 | 22.5 | 290 | 16-31 |

| SWP660E |

600 | 1000 | 500 | ≤10 | 210 | 544 | 380 | 450 | 55 | 15 | 90×55 | 27.5 | 360 | 22-34 |

| SWP640E |

640 | 1250 | 630 | ≤10 | 230 | 575 | 385 | 480 | 60 | 15 | 100×60 | 30 | 385 | 18-38 |

Detailed Photos

Packaging & Shipping

Company Profile

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and TS16949.

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all customers with customized PDF or AI format artwork.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have an excellent price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Recent Technological Advancements in Cardan Coupling Design

In recent years, there have been notable advancements and innovations in the design of cardan couplings:

- Material Enhancements: Advances in materials science have led to the development of high-strength and lightweight materials that can improve the performance and durability of cardan couplings.

- Sealing Technology: Improved sealing mechanisms and materials help prevent contamination and enhance the lifespan of cardan couplings.

- Computer-Aided Design (CAD): CAD software allows for more precise and optimized design of cardan couplings, leading to better performance and reduced stress concentrations.

- Finite Element Analysis (FEA): FEA techniques enable engineers to simulate the behavior of cardan couplings under various loads and conditions, aiding in design optimization.

- Lubrication Systems: Innovations in lubrication systems ensure efficient and consistent lubrication, reducing wear and enhancing coupling longevity.

- Monitoring and Diagnostics: Integration of sensors and monitoring systems enables real-time data collection for performance analysis, predictive maintenance, and early detection of issues.

- Customization: Advanced manufacturing techniques allow for more customization, making it possible to design cardan couplings tailored to specific applications.

These advancements contribute to the overall efficiency, reliability, and performance of cardan couplings, making them more suitable for a wide range of applications.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

Are there different types of cardan couplings for various applications?

Yes, there are different types of cardan couplings designed to suit various applications and requirements:

- Single Universal Joint: This is the most common type of cardan coupling, consisting of two yokes connected by a cross-shaped center piece. It is suitable for applications where angular misalignment compensation is needed, but the shafts are not too far apart.

- Double Cardan Joint: Also known as a double U-joint or CV joint, this type consists of two universal joints connected by an intermediate shaft. It is used when higher angles of misalignment need to be accommodated or when a constant velocity transmission is required.

- Disc Type Coupling: This type uses flexible discs or plates to transmit torque and compensate for misalignment. It is often used in applications with limited space and moderate torque requirements.

- Block Type Coupling: Block type cardan couplings use solid blocks or spheres to transmit torque. They are suitable for heavy-duty applications and can handle higher torque loads.

- Floating Shaft Coupling: This design involves two shafts connected by a third floating shaft, which allows for even higher angles of misalignment and smoother torque transmission.

- Needle Bearing Universal Joint: In this type, needle bearings are used to reduce friction and improve efficiency. It is often used in precision applications where low friction and high efficiency are crucial.

The choice of cardan coupling type depends on factors such as the amount of misalignment, torque requirements, available space, and the need for constant velocity transmission. Selecting the right type ensures optimal performance and longevity in various mechanical systems.

editor by CX 2024-02-27

China manufacturer Wuxi CHINAMFG Custom Made Coupling Cardan Shaft Coupling /U Joint Shaft for Rolling Mill

Product Description

HangZhou XIHU (WEST LAKE) DIS. custom made cardan shaft /U joint shaft for rolling mill

Brief Introduction

Processing flow

Applications

Quality Control

Product Description

| structure | universal | Flexible or Rigid | Rigid | Standard or Nonstandard | Nonstandard |

| Material | Alloy steel | Brand name | HangZhou XIHU (WEST LAKE) DIS. | Place of origin | ZheJiang ,China |

| Model | SWC225-250A-1400+600 | Raw materials | Castings/Forgings | Length | 1400mm+600mm |

| Flange DIA | 225(250)mm | Nominal torque | 40Kn | coating | heavy duty industrial paint |

| Paint clour | customization | Application | equipments | OEM/ODM | Available |

| Certification | ISO,TUV,SGS | Price | calculate according to model | Custom service | Available |

Packaging & Delivery

Packaging details:Standard plywood case

Delivery detail: 15 -20 working days,depend on the actual produce condition

FAQ

Q1: What is the location of your company?

A1: Our company is located in the HangZhou City ,ZheJiang ,China.Welcome to visit our factory at anytime!

Q2: How does your factory do regarding quality control?

A2: Our standard QC system to control quality.

Q3: What is your delivery time?

A3: Usually within 25 days after the receipt of payment.Delivery time must depend on the actual produce condition.

Q4: What are your strengths?

A4: 1.We are the manufacturer,having competitive advantage in price.

2.A large part of money is put into advancing CNC equipments and product

R&D department annual,the performance of cardan shaft can be guaranteed.

3.About quality issues or follow-up after-sales service,we report directly to the boss.

4.We have the ambitions to exploring and developing the world’s cardan shaft market and

we believe we can.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Diagnosing and Troubleshooting Cardan Coupling Issues

Diagnosing and troubleshooting issues related to cardan couplings in machinery systems involves a systematic approach:

- Visual Inspection: Examine the cardan coupling for signs of wear, damage, misalignment, or corrosion. Look for any unusual noises or vibrations.

- Check Lubrication: Inspect the lubrication system and ensure proper lubricant levels. Inadequate lubrication can lead to premature wear.

- Monitor Performance: Use sensors and monitoring systems to track the performance of the cardan coupling in real-time. Analyze data for anomalies.

- Measure Alignment: Check for proper alignment between the input and output shafts. Misalignment can lead to increased wear and reduced efficiency.

- Check for Unusual Noises: Listen for any unusual noises during operation, such as grinding, squeaking, or knocking sounds.

- Inspect Components: Examine the individual components of the cardan coupling, including the universal joints and shafts, for signs of wear or damage.

- Perform Load Analysis: Evaluate the operating conditions and loads to ensure they are within the specified limits of the cardan coupling.

- Review Maintenance Records: Refer to maintenance records to ensure that the cardan coupling has been properly maintained and serviced.

- Consult Manufacturer Guidelines: Follow the manufacturer’s guidelines for troubleshooting and diagnostics specific to the cardan coupling model.

By following these steps, operators and maintenance personnel can effectively diagnose and troubleshoot cardan coupling issues, ensuring the reliable and efficient operation of machinery systems.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

Factors to Consider When Selecting a Cardan Coupling for Specific Applications

Choosing the right cardan coupling for a specific application requires careful consideration of various factors:

- Torque and Power Transmission: Determine the required torque and power capacity of the coupling to ensure it can handle the intended load without exceeding its limits.

- Angular Misalignment: Assess the level of angular misalignment that might occur between the connected shafts and choose a coupling that can accommodate it without causing excessive wear or vibration.

- Operating Speed: Consider the rotational speed of the shafts to ensure that the coupling’s design can handle the desired speed without causing issues like resonance or fatigue.

- Environmental Conditions: Evaluate the operating environment, including factors like temperature, humidity, and exposure to contaminants, to select a coupling made from materials that can withstand these conditions.

- Shaft Sizes and Types: Measure the diameter and type of shafts that need to be connected and choose a coupling with compatible dimensions and attachment methods.

- Space Constraints: Consider the available space for the coupling within the machinery and select a compact design that fits without causing interference.

- Maintenance Requirements: Evaluate the maintenance practices and frequency that will be feasible for your application and choose a coupling that aligns with those requirements.

- Cost and Budget: Factor in the cost of the coupling and its potential impact on your budget while ensuring that the chosen coupling meets your performance needs.

- Shock and Vibration: Determine if the application involves high levels of shock or vibration and select a coupling that can absorb or mitigate these forces to prevent premature failure.

- Life Cycle and Reliability: Consider the expected lifespan of the machinery and choose a coupling that offers the desired level of durability and reliability.

By carefully considering these factors, you can select the most suitable cardan coupling for your specific application, ensuring optimal performance and longevity.

editor by CX 2024-02-11

China Custom 42cr/45# Transmission Parts Coupled Drive Shaft Universal Coupling/Cardan Propeller Shaft Coupling

Product Description

Densen customized SWC-BF Type universal coupling shaft coupling,universal couplings joint

We have professionals to solve your questions, please contact us directly!

| Product Name | Densen customized SWC-BF Type universal coupling shaft coupling,universal couplings joint |

| DN mm | 160~640mm |

| Axis Angle | 25/15° |

| Rated Torque | 16~1250 N·m |

| Fatigue torque | 8~630N·m |

| Material | 35CrMo |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Materials Used in Manufacturing Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are crucial components in mechanical systems that transmit torque and accommodate angular misalignment. These couplings are manufactured using a variety of materials to ensure durability, reliability, and performance. Common materials used in the manufacturing of cardan couplings include:

1. Steel: Steel is a widely used material due to its high strength, durability, and resistance to wear and corrosion. Alloy steels are often chosen for their enhanced mechanical properties and fatigue resistance.

2. Cast Iron: Cast iron is used in some cardan couplings, especially in older or heavier-duty applications. It provides good strength and vibration dampening properties.

3. Aluminum: Aluminum is chosen for its lightweight properties, making it suitable for applications where weight reduction is important. It is commonly used in industries such as automotive and aerospace.

4. Stainless Steel: Stainless steel is used when corrosion resistance is a critical factor. It is commonly employed in environments where the coupling may be exposed to moisture or corrosive substances.

5. Bronze: Bronze can be used in certain applications where self-lubricating properties are desired. It also provides good wear resistance.

6. Synthetic Polymers: Some modern cardan couplings use synthetic polymers or plastics in their construction to reduce weight and provide specific performance characteristics, such as dampening vibrations.

The choice of material depends on factors like the application requirements, operational conditions, torque transmission, operating speed, and environmental factors. Manufacturers select materials that offer the best combination of strength, durability, wear resistance, and corrosion resistance for the specific use case of the cardan coupling.

What is a cardan coupling and how is it used in mechanical systems?

A cardan coupling, also known as a universal joint or U-joint coupling, is a mechanical component used to transmit torque between two shafts that are not in alignment but intersect at an angle. It consists of a cross-shaped yoke with two perpendicular shafts connected at its ends, allowing the transmission of rotational motion even when the shafts are at different angles to each other. Cardan couplings are widely used in mechanical systems to transmit torque and motion where angular misalignment is present.

Here’s how a cardan coupling works and how it is used in mechanical systems:

- Angular Misalignment: Cardan couplings are designed to accommodate angular misalignment between shafts. They can transmit torque between shafts that are at an angle to each other, typically up to 45 degrees. This ability to handle misalignment makes them suitable for various applications.

- Components: A cardan coupling consists of a cross-shaped yoke with four arms, two of which are connected to the input and output shafts. The two remaining arms are connected to each other through a bearing, which allows for the rotational motion.

- Transmitting Torque: As one shaft rotates, it imparts angular motion to the yoke. This angular motion is transferred to the other shaft through the bearing, allowing torque to be transmitted even when the shafts are not collinear.

- Application: Cardan couplings are used in various applications, including automotive drivetrains, industrial machinery, agricultural equipment, and even in some aerospace systems. They are often found in places where it’s necessary to transmit torque between non-parallel shafts while allowing for some degree of flexibility.

- Advantages: Cardan couplings are simple in design, relatively compact, and provide a cost-effective solution for transmitting torque in cases of angular misalignment. They are also capable of transmitting high torques while compensating for misalignment.

- Limitations: Cardan couplings have limitations in terms of the angle they can handle, and at extreme angles, they may produce uneven torque output due to their design. They can also introduce some degree of vibration and require periodic maintenance.

In mechanical systems, cardan couplings are used in various applications where the alignment between shafts cannot be maintained, such as in vehicles with independent suspension systems, industrial machinery with non-parallel shafts, and applications where flexibility and torque transmission are required despite angular misalignment.

editor by CX 2023-12-19

China Custom Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

Product Description

Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc CHINAMFG Flex Rigid Drive Shaft NM yox Fluid Jaw Flexible Chain Gear Couplings

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Production workshop:

Company information:

Maintenance Practices for Ensuring Cardan Coupling Reliability

To ensure the reliability of cardan couplings, the following maintenance practices are crucial:

- Lubrication: Regularly inspect and maintain the lubrication system. Ensure proper lubricant levels and use lubricants recommended by the manufacturer.

- Alignment: Maintain proper alignment between the input and output shafts. Misalignment can lead to premature wear and reduced efficiency.

- Regular Inspections: Perform visual inspections to detect signs of wear, damage, or corrosion. Regular inspections can help identify issues before they become major problems.

- Monitoring: Use sensors and monitoring systems to track the performance of the cardan coupling. Monitor temperature, vibration, and other parameters for anomalies.

- Torque Analysis: Analyze the torque requirements of the machinery system to ensure that the cardan coupling can handle the load without exceeding its limits.

- Periodic Maintenance: Follow the manufacturer’s recommended maintenance schedule. This may include replacing worn components, lubricant changes, and alignment adjustments.

- Record Keeping: Maintain detailed maintenance records, including inspection dates, lubrication schedules, and any repairs performed.

- Training: Ensure that maintenance personnel are trained to properly inspect, maintain, and troubleshoot cardan couplings.

By implementing these maintenance practices, operators can extend the lifespan of cardan couplings, prevent unexpected failures, and optimize the performance of machinery systems.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

Are there different types of cardan couplings for various applications?

Yes, there are different types of cardan couplings designed to suit various applications and requirements:

- Single Universal Joint: This is the most common type of cardan coupling, consisting of two yokes connected by a cross-shaped center piece. It is suitable for applications where angular misalignment compensation is needed, but the shafts are not too far apart.

- Double Cardan Joint: Also known as a double U-joint or CV joint, this type consists of two universal joints connected by an intermediate shaft. It is used when higher angles of misalignment need to be accommodated or when a constant velocity transmission is required.

- Disc Type Coupling: This type uses flexible discs or plates to transmit torque and compensate for misalignment. It is often used in applications with limited space and moderate torque requirements.

- Block Type Coupling: Block type cardan couplings use solid blocks or spheres to transmit torque. They are suitable for heavy-duty applications and can handle higher torque loads.

- Floating Shaft Coupling: This design involves two shafts connected by a third floating shaft, which allows for even higher angles of misalignment and smoother torque transmission.

- Needle Bearing Universal Joint: In this type, needle bearings are used to reduce friction and improve efficiency. It is often used in precision applications where low friction and high efficiency are crucial.

The choice of cardan coupling type depends on factors such as the amount of misalignment, torque requirements, available space, and the need for constant velocity transmission. Selecting the right type ensures optimal performance and longevity in various mechanical systems.

editor by CX 2023-11-07

China Custom No Telescopic Shorten Universal Cardan Shaft Coupling (SWP-C)

Product Description

No Telescopic short cardan shaft Coupling(SWP-C)

Cardan shaft is widely used in rolling mill, punch, straightener, crusher, ship drive, paper making equipment, common machinery, water pump equipment, test bench, and other mechanical applications.

Advantage:

1. Low life-cycle costs and long service life;

2. Increase productivity;

3. Professional and innovative solutions;

4. Reduce carbon dioxide emissions, and environmental protection;

5. High torque capacity even at large deflection angles;

6. Easy to move and run smoothly;

|

Model |

D mm |

Tn KN·m |

Tf KN·m |

β |

S mm |

mm |

||||||||

|

D1 |

D2 |

D3 |

E |

E1 |

b×h |

h1 |

L1 |

n-d |

||||||

|

SWP160C |

160 |

16 |

8 |

≤10 |

50 |

140 |

95 |

114 |

15 |

4 |

20×12 |

6 |

85 |

6-13 |

|

SWP180C |

180 |

20 |

10 |

≤10 |

60 |

155 |

105 |

121 |

15 |

4 |

24×14 |

7 |

95 |

6-15 |

|

SWP200C |

200 |

31.5 |

16 |

≤10 |

70 |

175 |

125 |

127 |

17 |

5 |

28×16 |

8 |

110 |

8-15 |

|

SWP225C |

225 |

40 |

20 |

≤10 |

76 |

196 |

135 |

152 |

20 |

5 |

32×18 |

9 |

130 |

8-17 |

|

SWP250C |

250 |

63 |

31.5 |

≤10 |

80 |

218 |

150 |

168 |

25 |

5 |

40×25 |

12.5 |

135 |

8-19 |

|

SWP285C |

285 |

90 |

45 |

≤10 |

100 |

245 |

170 |

194 |

27 |

7 |

40×30 |

15 |

150 |

8-12 |

|

SWP315C |

315 |

140 |

63 |

≤10 |

110 |

280 |

185 |

219 |

32 |

7 |

40×30 |

15 |

170 |

10-23 |

|

SWP350C |

350 |

180 |

90 |

≤10 |

120 |

310 |

210 |

245 |

35 |

8 |

50×32 |

16 |

185 |

10-23 |

|

SWP390C |

390 |

250 |

112 |

≤10 |

120 |

345 |

235 |

273 |

40 |

8 |

70×36 |

18 |

205 |

10-25 |

|

SWP435C |

435 |

355 |

160 |

≤10 |

150 |

385 |

255 |

299 |

42 |

10 |

80×40 |

20 |

235 |

16-28 |

|

SWP480C |

480 |

450 |

224 |

≤10 |

170 |

425 |

275 |

351 |

47 |

12 |

90×45 |

22.5 |

265 |

16-31 |

|

SWP550C |

550 |

710 |

315 |

≤10 |

190 |

492 |

320 |

402 |

50 |

12 |

100×45 |

22.5 |

290 |

16-31 |

|

SWP660C |

600 |

1000 |

500 |

≤10 |

210 |

544 |

380 |

450 |

55 |

15 |

90×55 |

27.5 |

360 |

22-34 |

|

SWP640C |

640 |

1250 |

630 |

≤10 |

230 |

575 |

385 |

480 |

60 |

15 |

100×60 |

30 |

385 |

18-38 |

Packaging & Shipping

Company Profile

HangZhou CZPT Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and TS16949.

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all customers with customized PDF or AI format artwork.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have an excellent price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

Phasing in Cardan Couplings and Its Impact on Performance

The concept of phasing in cardan couplings refers to the alignment of the universal joints’ yokes or flanges on the input and output shafts. Proper phasing is essential to minimize angular misalignment and maintain smooth rotational motion. When the yokes of the universal joints are not aligned correctly, it can result in uneven torque transmission, increased wear, and vibrations.

Phasing affects the performance of cardan couplings in several ways:

- Uniform Torque Transmission: Proper phasing ensures that torque is evenly distributed between the input and output shafts, reducing the risk of overloading individual universal joints.

- Reduced Vibrations: Correctly phased universal joints minimize angular misalignment, which helps reduce vibrations and noise in the machinery system.

- Extended Lifespan: Improved phasing leads to reduced wear and stress on the universal joint components, extending the overall lifespan of the coupling.

- Efficient Power Transmission: Proper phasing contributes to efficient power transmission by minimizing energy losses due to misalignment.

To achieve proper phasing, manufacturers often provide guidelines or marks on the coupling components to ensure accurate alignment. It’s essential to follow these guidelines during installation and any maintenance or adjustments to maintain optimal performance and reliability of the cardan coupling.

Common Industries and Applications of Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used in various industries and applications that require torque transmission and flexibility in shaft connections. Some common examples include:

- Automotive Industry: Cardan couplings are used in driveshafts to transmit power from the engine to the wheels while allowing for variable angles and misalignment caused by suspension movement.

- Industrial Machinery: They are used in heavy machinery such as mining equipment, cranes, and manufacturing machinery to transmit torque between non-aligned shafts.

- Agricultural Machinery: Tractors and other agricultural equipment utilize cardan couplings in drivelines to accommodate varying angles and lengths.

- Marine Applications: Cardan couplings are used in marine propulsion systems to transmit torque between the engine and the propeller shaft, even when the shafts are at different angles.

- Aerospace Industry: They are employed in aerospace applications such as aircraft control systems and helicopter rotor drives to accommodate movements and misalignments.

- Railway Systems: Cardan couplings are used in railway drivelines to transmit torque between cars and locomotives while allowing for movement and misalignment.

- Energy Sector: They find applications in power generation systems, including wind turbines, where they accommodate misalignments caused by dynamic loads.

- Pumps and Compressors: Cardan couplings are used in pumps and compressors to transmit power while compensating for misalignment and vibration.

These examples demonstrate the versatility of cardan couplings in various industries where torque transmission, flexibility, and angular misalignment compensation are essential.

Factors to Consider When Selecting a Cardan Coupling for Specific Applications

Choosing the right cardan coupling for a specific application requires careful consideration of various factors:

- Torque and Power Transmission: Determine the required torque and power capacity of the coupling to ensure it can handle the intended load without exceeding its limits.

- Angular Misalignment: Assess the level of angular misalignment that might occur between the connected shafts and choose a coupling that can accommodate it without causing excessive wear or vibration.

- Operating Speed: Consider the rotational speed of the shafts to ensure that the coupling’s design can handle the desired speed without causing issues like resonance or fatigue.

- Environmental Conditions: Evaluate the operating environment, including factors like temperature, humidity, and exposure to contaminants, to select a coupling made from materials that can withstand these conditions.

- Shaft Sizes and Types: Measure the diameter and type of shafts that need to be connected and choose a coupling with compatible dimensions and attachment methods.

- Space Constraints: Consider the available space for the coupling within the machinery and select a compact design that fits without causing interference.

- Maintenance Requirements: Evaluate the maintenance practices and frequency that will be feasible for your application and choose a coupling that aligns with those requirements.

- Cost and Budget: Factor in the cost of the coupling and its potential impact on your budget while ensuring that the chosen coupling meets your performance needs.

- Shock and Vibration: Determine if the application involves high levels of shock or vibration and select a coupling that can absorb or mitigate these forces to prevent premature failure.

- Life Cycle and Reliability: Consider the expected lifespan of the machinery and choose a coupling that offers the desired level of durability and reliability.

By carefully considering these factors, you can select the most suitable cardan coupling for your specific application, ensuring optimal performance and longevity.

editor by CX 2023-08-14

Best China manufacturer & factory Agricultural in Aba Nigeria Machinery Custom Competitive Low Price Pto Shaft With Lemon Yoke With high quality best price

The higher exact CNC equipment, this sort of as Sluggish-feeding wire-reduce machine, jig grinding machine and electric discharge device, makes certain the top good quality precision of mould processing, with the substantial efficient and environmental security acid rolling line currently being the greatest raw substance converting gear in the area in china The wildly use of automatic milling machine, substantial-velocity computerized feeding punch, large speed automated rolling and assembling machine guarantees the high high quality and effectiveness of parts and chain producing.

Overview

Fast Particulars

- Guarantee:

-

one.5 many years

- Applicable Industries:

-

Manufacturing Plant

- Soon after Warranty Support:

-

On the web assistance

- Local Provider Location:

-

none, Italy

- Showroom Location:

-

ITALY

Worm gearboxes are observed for dependable electricity transmission. Computer-aided assembly of the Morse Raider gearbox eradicates outcomes of cumulative production tolerances and assists increase functioning effectiveness. The device also attributes a redesigned breather and textured shaft surface, letting the manufacturer offer you an eighteen-thirty day period leak-free of charge promise. An automatic centering machine measures gearbox factors and guides assembly to increase operating effectiveness.

- Place of Origin:Zhejiang, China

- Model Identify:

-

OEM

- certification:

-

EPG key creation is of farming 15-five hundred horsepower tractor supporting machinery, mechanical cultivation, harvesting equipment and add-ons.

CE

- Substance:

-

Metallic

- Processing of yoke:

-

Forging

If you are hunting for a 540 PTO shaft, 540 to 1000 PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, look no even more. It is important to exchange PTO parts that are worn or cracking just before you have a significant breakdown that could be high-priced and even dangerous. We have PTO generate shafts as properly as important shield parts for your safety. Our Eurocardan components incorporate a range of varieties of clutches to enhance the procedure of your electrical power take-off technique. PTO shafts and equipment are an critical component of the more than 26,000 objects we carry for farm, store, house and garden.

- Design:

-

Personalized

- Certification:

-

CE Certificate

Provide Capability

- Source Capability:

- 80000 Piece/Pieces for every Month

Packaging & Shipping

- Packaging Information

- Regular export packing

- Port

- NINGBO OR SHANGHAI

On-line Customization

Item Details

Item Info

PTO Shaft

The power take-off (PTO) is a innovative mechanism, making it possible for implements to draw power from the motor and transmit it to another software. It performs as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The energy take-off shaft (PTO shaft) is a essential component, designed and produced for constant weighty-duty use. A excellent PTO shaft should be sturdy adequate to bear the torsion and shear anxiety and minimize vibration.

Setforge, the forging subsidiary of Ever-Electricity Group, manufactures chilly extruded PTO shafts for all types of agriculture autos. Our PTO shafts offer you great dependability and toughness in the course of day-to-day use.

EP Group has been internationally identified as a dependable international provider. Our state-of-the-art manufacturing procedure and seasoned engineers make certain the leading-top quality of all Farinia factors.

| Following Warranty Provider | Video clip complex support |

| Applicable Industries | Production Plant |

| Nearby Service Location | Italy |

| Showroom Area | Italy |

| Guarantee | 1.5 many years |

| Area of Origin | China |

| China | Zhejiang |

| Brand name Identify | EPG |

| certification | CE |

| Content | Metallic |

| Processing of yoke | Forging |

| Style | Tailored |

| Certificate | CE Certification |

Item Screen

Solution Screen

L sequence aluminium …

HP21 Skid Steer Au …

fifteen” Heavy Obligation Ear …

CompanyInfo

Firm Profile

Ever-Electrical power Group

EPG have substantial-tech machinery and test tools. We can generate entire world course higher precision merchandise.

Certifications

Certifications

Cargo & Payment

Our Rewards

A: Your inquiry associated to our products or prices will be replied in 24 hours.

B: Security of your income location, suggestions of style and all your private info.

C: Greatest quality and competitive price.

……

faq

FAQ

1) How can I location buy?

A: You can speak to us by e-mail about your purchase details, or area buy on line.

2) How can I shell out you?

A: Following you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most typical methods we are utilizing.

……

High China 2010 camaro driveshaft Quality Custom Square Pto Drive Shaft Tractor Agricultural Components China Factory Manufacturer with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto factory in China with 5 diverse branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

corsa d driveshaft f350 travel shaft u joint replacement EPG two piece driveshaft is pto shaft collection six one-three/8 six-spline specialized nissan titan generate shaft in ford 4000 pto shaft put in design, mercedes front generate shaft substitution company pto shaft for tiller and 2001 ford f150 travel shaft revenue push shaft saga of agricultural equipment and farm implements, which has an unbiased import and export legal rights. The company was licensed by ISO9001:2008 Quality Management System.

substantial high quality personalized sq. pto generate shaft tractor agricultural factors china manufacturing unit manufacturer

Precision China ford f250 drive shaft in Mexico City Mexico Custom Stainless Steel Industrial Transmission Drive Shaft for Gear with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto manufacturing facility in China with 5 diverse branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

1 inch fifteen spline pto shaft Below pto shaft star tubing the pto shaft h2o pump advice pto appropriate angle gearbox of bush hog pto shaft tractor offer managerial pto shaft trapped on mower feeling pto shaft pin tractor provide of kubota pto shaft measurement “Serving renault clio push shaft agriculture, pto hydraulic piston pump scoring a success by way of high quality of items and honesty in business”, our products have been trusted by clientele and have obtained a bigger share of marketplace. Our merchandise is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The united states, Thailand, Pakistan, Indonesia, a lot more than 60 nations and areas. At EPT Business, we use the latest machining technology with a wide selection of capabilities to fulfill your requires. Our producing faXiHu (West Lake) Dis.ties contain 3-5 axis milling, lathes, grinding, and so forth, and point out of the artwork metrology. With these equipment, we produce complicated elements in the most successful and precise way. Our producing capabilities allow us to deveXiHu (West Lake) Dis. your component from prototype to mass production for the most precise of jobs.

| Processing Technique | CNC Milling, CNC Turning, Turning-Milling Machining, Micro Machining, Grinding, Dull, Tapping. |

| Content | Stainless Metal, Alloy Metal, Carbon Steel, Free of charge-reducing Steel, Brass, Copper, Aluminum, POM, PTFE. |

| Finish Therapy | PoXiHu (West Lake) Dis.ng, Sand Blasting, Anodizing, Zinc Plating, Nickel Plating, Blackening, QPQ, Painting, and so forth.. |

| Tech. StHangZhourd | ANSI, ASTM, DIN, JIS, BS, GB, ISO, etc.. |

| Software | Health care, Aerospace, Millitary, Instrument, Optics, Foods Tools, Auto Components, Furniture, and many others.. |

Precision Machining is the most import EPT sector in EPT Market, we have been a trusted manufacturing supplier in this field for more than 15 many years. We have created an impeccable popularity on quality, consumer support and using point out-of-the-artwork products. Our skills has manufactured us the Ideal in Quality and Innovation.

Machining FaXiHu (West Lake) Dis.ties

| Products Description | Workpiece Proportions | Processing Accuracy | Quantities | Brand |

| three-axis machining middle | Max. 1000 x 1200mm | +/-.01mm | 6 | DMG |

| 4-axis machining middle | Max. 1000 x 1500mm | +/-.01mm | four | DMG |

| five-axis machining center | Max. a thousand x 1500mm | +/-.01mm | two | DMG |

| CNC lathe | Max. diameter 100mm | +/-.01mm | twenty | SMTCL |

| Standard lathe | Max. diameter 500mm | +/-.05mm | two | SMTCL |

| Turning-Milling equipment | Max. diameter 100mm | +/-.01mm | six | DMG |

| Longitudinal lathe | Max. diameter 30mm | +/-.01mm | six | TSUGAMI |

| Computerized lathe | Max. diameter 20mm | +/-.02mm | thirty | TY |

| CNC Swiss Lathe | Max. diameter 20mm | +/-.01mm | 6 | TSUGAMI |

Other help equipments incorporate:

Milling device, Drilling device, Centerless Grinding machine, Exterior Cylindrical Grinding equipment, and many others.

Inspection tools:

Vernier Caliper, Micrometer, Height Gage, Hardness Tester, Two-dimensional picture measuring instrument, TESA Micro-Hite

three hundred, Mitutoyo floor Roughness Tester, Mitutoyo CMM and Ultrasonic Cleaner.

FAQ

Q1: Are you a buying and selling organization or a manufacturer?

Manufacturer.

Q2: How long is your supply time?

Typically, the samples supply is ten-fifteen times and the lead time for the official buy is thirty-45 days.