Product Description

Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc CZPT Flex Rigid Drive Shaft NM yox Fluid Jaw Flexible Chain Gear Couplings

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Production workshop:

Company information:

Recent Technological Advancements in Cardan Coupling Design

In recent years, there have been notable advancements and innovations in the design of cardan couplings:

- Material Enhancements: Advances in materials science have led to the development of high-strength and lightweight materials that can improve the performance and durability of cardan couplings.

- Sealing Technology: Improved sealing mechanisms and materials help prevent contamination and enhance the lifespan of cardan couplings.

- Computer-Aided Design (CAD): CAD software allows for more precise and optimized design of cardan couplings, leading to better performance and reduced stress concentrations.

- Finite Element Analysis (FEA): FEA techniques enable engineers to simulate the behavior of cardan couplings under various loads and conditions, aiding in design optimization.

- Lubrication Systems: Innovations in lubrication systems ensure efficient and consistent lubrication, reducing wear and enhancing coupling longevity.

- Monitoring and Diagnostics: Integration of sensors and monitoring systems enables real-time data collection for performance analysis, predictive maintenance, and early detection of issues.

- Customization: Advanced manufacturing techniques allow for more customization, making it possible to design cardan couplings tailored to specific applications.

These advancements contribute to the overall efficiency, reliability, and performance of cardan couplings, making them more suitable for a wide range of applications.

Handling High Torque and Axial Displacement with Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are designed to transmit torque between two shafts that are not in a straight line. They are versatile components commonly used in various applications, including those requiring high torque and axial displacement.

Handling High Torque: Cardan couplings are capable of handling high levels of torque transmission due to their robust design and construction. The design allows for torque to be transmitted through a series of interconnected components, including the cross-shaped yokes and the bearing assemblies. The use of high-strength materials and precision manufacturing techniques contributes to the coupling’s ability to transmit torque efficiently.

Handling Axial Displacement: While cardan couplings are primarily designed for accommodating angular misalignment, they can also handle a certain degree of axial displacement. Axial displacement refers to the movement of the connected shafts along their axis. However, the axial displacement capacity of a cardan coupling is limited compared to its ability to handle angular misalignment.

It’s important to note that excessive torque or axial displacement beyond the coupling’s design limits can lead to premature wear, increased vibrations, and reduced performance. Manufacturers provide specifications and guidelines for the maximum torque and axial displacement that a specific cardan coupling can handle. Engineers and designers should adhere to these specifications to ensure optimal performance and longevity of the coupling in their applications.

Factors to Consider When Selecting a Cardan Coupling for Specific Applications

Choosing the right cardan coupling for a specific application requires careful consideration of various factors:

- Torque and Power Transmission: Determine the required torque and power capacity of the coupling to ensure it can handle the intended load without exceeding its limits.

- Angular Misalignment: Assess the level of angular misalignment that might occur between the connected shafts and choose a coupling that can accommodate it without causing excessive wear or vibration.

- Operating Speed: Consider the rotational speed of the shafts to ensure that the coupling’s design can handle the desired speed without causing issues like resonance or fatigue.

- Environmental Conditions: Evaluate the operating environment, including factors like temperature, humidity, and exposure to contaminants, to select a coupling made from materials that can withstand these conditions.

- Shaft Sizes and Types: Measure the diameter and type of shafts that need to be connected and choose a coupling with compatible dimensions and attachment methods.

- Space Constraints: Consider the available space for the coupling within the machinery and select a compact design that fits without causing interference.

- Maintenance Requirements: Evaluate the maintenance practices and frequency that will be feasible for your application and choose a coupling that aligns with those requirements.

- Cost and Budget: Factor in the cost of the coupling and its potential impact on your budget while ensuring that the chosen coupling meets your performance needs.

- Shock and Vibration: Determine if the application involves high levels of shock or vibration and select a coupling that can absorb or mitigate these forces to prevent premature failure.

- Life Cycle and Reliability: Consider the expected lifespan of the machinery and choose a coupling that offers the desired level of durability and reliability.

By carefully considering these factors, you can select the most suitable cardan coupling for your specific application, ensuring optimal performance and longevity.

editor by CX 2023-08-11

China manufacturer & factory supplier for wenzhou in West Yorkshire United Kingdom coaxial transmission speed reducer motor engine spiral transmission lifting equipment steering gear box lifting jack With high quality best price & service

ISO 9001:2015 certified producer and distributor of roller chains. Kinds of roller chains contain ASME/ANSI standard chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, totally free-movement chains, specialty chains and British common chains. ASME/ANSI standard chains are obtainable in massive and tiny pitch, double pitch and leaf styles. Roller chains are utilised in meals packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and electricity transfer applications.We have exported our goods to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states of america, Canada, and many others.

Overview

Quick Particulars

- Applicable Industries:

-

Manufacturing Plant, Machinery Fix Stores, Foods & Beverage Factory, Farms

- Area of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Velocity:

-

1400rpm

- Output Speed:

-

fourteen-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Place:

-

Foot Mounted

- Bearing:

-

LYC,SKF

Source Potential

- Supply Capacity:

- five hundred Unit/Models for every Month

Packaging & Shipping and delivery

- Packaging Particulars

- Wood containers , Cantons packed in 1 pallet

Our goods is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, more than sixty countries and regions.

- Port

- Ningbo Port, Shanghai Port

On-line Customization

Item Description

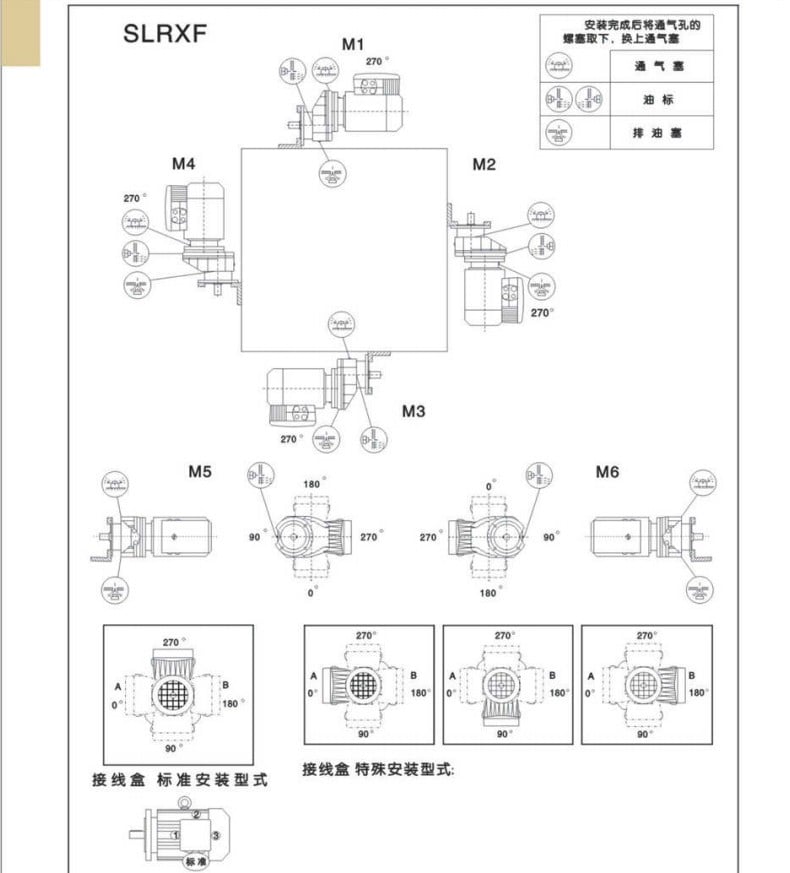

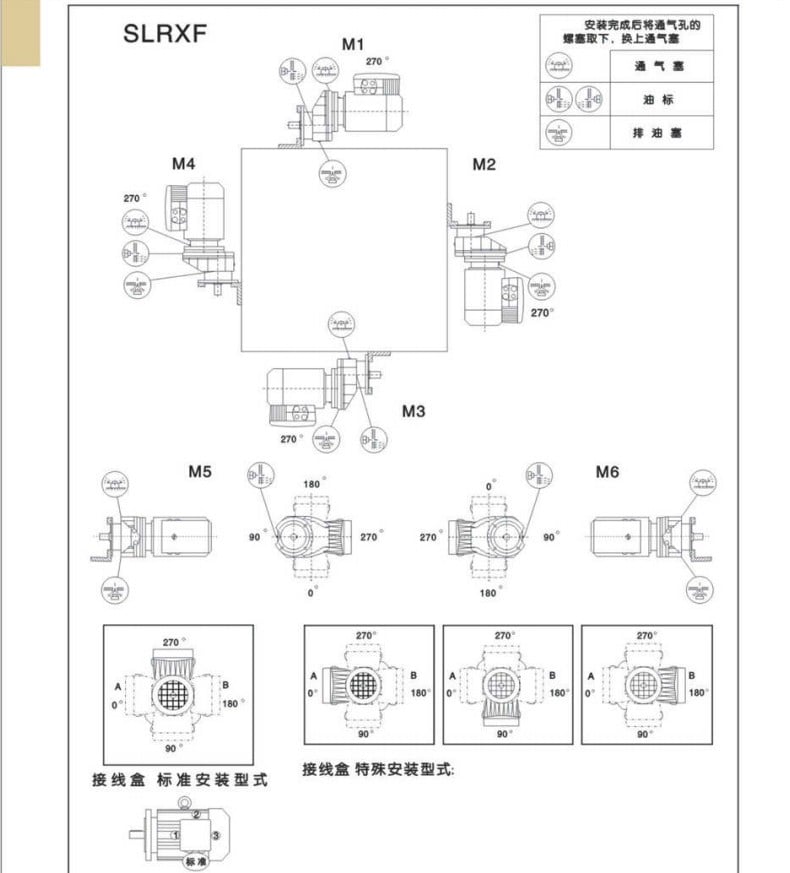

SLR helical reducer has the features of large versatility,very good blend and weighty loading functionality, alongside with other merits this kind of as straightforward to achieve a variety of transmission ratios, high performance, reduced vibrationand large permissible axis radial load. This series can not only be combined with a variety of kinds of reducers and variators and meet the requirements, but also beadvantage of localization of relevant transmission tools.

Requirements:

1) Output pace: .6~1,028r/min

2) Output torque: up to eighteen,000N.m

three) Motor energy: .eighteen~160kW

4) Mounted kind: foot-mounted and flange-mounted mounting

|

Product Identify |

SLR Collection Rigid Tooth helical reducer |

|

Equipment Material |

20CrMnTi |

|

Situation Substance |

HT250 |

|

Shaft MaterialA power just take-off or power takeoff (PTO) is any of several strategies for having power from a power supply, such as a operating motor, and transmitting it to an application this kind of as an attached apply or separate device. |

20CrMnTi |

|

Equipment Processing |

Grinding end by HOFLER Grinding Equipment |

|

Color |

Custom-made |

|

Sounds Check |

Bellow 65dB |

Certifications

Trade Exhibits

Packaging & Transport

Packing Details : Standard carton/Pallet/Standard wooden case

Shipping Specifics : 15-thirty woOur stepper and BLDC motors, linear actuators and linear positioning drives, in dimensions commencing at 10 mm, collectively with a variety of gearboxes and encoders, blend into a modular system with above 4000 attainable combinations. In addition, you can pick from a selection of shaft, flange and connector varieties that quickly and reliably link to current unit architecture. The efficiency and resonance actions of EPG motors is optimized by smart motor controllers that meet the latest technological innovation expectations.rking times on payment

Firm Info

other collection item

| Precision Planetary gearbox | Robotic RV gearbox pace reducer |

| Personalized created Non-normal Gearbox | UDL Collection Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series High Electricity Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Related Products

Speak to

China manufacturer & factory supplier for All in Dallas United States china price parallel shaft gearbox F57 FA57 FAF57 FF57 helical gear reductor with 3hp motor With high quality best price & service

roller chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also available. Other electrical power transmission merchandise contain pillow blocks, conveyor idlers, conveyor pulleys, generate shafts, equipment racks, gear reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, velocity reducers, sprockets, tapered bushings, tensioners, torque limiters, and universal joints. Solutions this kind of as bearing reconditioning and repair, ball screw fix, custom agreement machining, gearbox fix and overrunning clutch restore solutions are obtainable. Roller chains can be utilised in conveyor and equipment production, industrial processing, machine rebuilding, waste water, sand and gravel, resource and die, metal, metals and scrap processing industrial applications.Our AdvantagesProducts Large volume in Stock, No MOQ needed We comply with all the worldwide expectations, such as ISO9001 and TS16949 specifications.

Overview

Fast Specifics

- Relevant Industries:

-

Production Plant

- Brand Identify:

-

OEM

- Item NO:

-

SYF

- Mounting Placement:

-

Foot Mounted. Flange Mounted

- Ratio:

-

one.3-58800

- Bearing:

-

NSK Bearing

- Warranty:

-

1-2 Years

- Certificate:

-

ISO9001

- Enter speed:

-

-3000rpm/min

- Output velocity:

-

.1-356rpm/min

- Output torque:

-

-18000N.m

- Motor energy:

-

.18-11kw

Packaging & Shipping and delivery

-

Guide Time

: -

Quantity(Items) one – 1 two – five 6 – 10 >10 Our business has reliable financial power, builds up a technician crew contingent with large good quality, possesses the production assembly line of technicalization in China and perfect system examining on product top quality and operates marketing and advertising networks all through the place.

Est. Time(times) 5 ten fifteen To be negotiated

On the web Customization

Item Description

F Sequence PARALLEL SHAFT HELICAL Gear REDUCER

F series parallel shaft helical equipment reducer has the characteristics of tiny volume, mild weight, big transfer torque, reduced strength consumption, large performance, low temperature increase, strong load force and different construction forms. Appropriate for various set up situations.

It can be mixed with R collection, K series, S series, etc. to obtain reduced pace and greater torque.

F Collection Construction DRAWING

|

OUTPUT Velocity: |

.1~356 r/min |

|

OUTPUT TORQUE: |

≤18000 N.m |

|

Power: |

.eighteen~11kw |

|

MOUNTING Variety: |

Foot-mounted Foot-mounted and Hollow- mounted Hollow-shaft B5 Flange-mounted B5 Flange-mounted and Hollow- mounted B14Flange-mounted and Hollow- mounted |

PRECISION BEVEL Gear

20CrMn Ti materials – lower carbon alloy steel

Imported equipment grinding device processing, substantial hardness, steady functionality.

Vacuum furnace carburizing heat therapy, carburizing layer uniform.

Substantial Quality SHELL Material

The box body is manufactured of HT200 materials,which is cleaned by professional screening and washing products to ensAre you looking for a PTO drinking water pump or PTO- pushed generator? Hundreds of PTO parts from EPG indicate you can uncover PTO shaft elements and accessories for what ever sort of equipment you’re functioning with. From PTO generate shafts to defend areas, we have dozens of replacement PTO components. We stock Eurocardan elements as well as Neapco parts because those are names you can have faith in. Whether or not you want flex couplers or PTO shaft assemblies, we can support.ure that the internal cavity of the box entire body is cleaner without iron filings.

Substantial Good quality OUTPUT SHAFT

New regular axle, multi-precision machining, by way of rigorous dynamic and static equilibrium test, to make certain reduced sounds and easy procedure of reducer

Skilled AIR TIGHTNRSS Test

Prior to spraying every single reducer, air tightness take a look at is needed to reduce the prevalence of oil leakage and air leakage. Make certain the lengthy life and excellent procedure of the reducer.

F Collection HELICAL Gear Units OVERVIEW:

●Parallel output,construction compact,carrying greater torque,operation steady,voice low,life time prolonged.

●Mounting mode :foot-mounted,flange-mounted,torque arm-mounted.

●Ratio:ratio of 2-stage is 8.1-191,ratio of 3-phase is 28.2-273,ratio of mixture is up to 18509.

●For 2-stage standard variety geared,rotation direction of input shaft is the identical that of output shaftfor 3-phase fundamental variety geared,their instructions are reversefor combination,remember to contact At any time Energy.

●Output manner:hollow shaft output or strong shaft output.

●Average performance: 2-phase 96%, 3-phase ninety four%,combination eighty five%.

F Sequence PARALLEL SHAFT HELICAL Equipment REDUCER MOUNTING DIMENSIONS OUTPUT SHAFT DIMENSIONS

F foot shaft mounting parallel helical equipment reducer

FA hollow shaft mounting parallel shaft helical equipment reducer

FF flange shaft mounting parallel shaft helical gear reducer

If the equipment reducer had to be painted, the detents have to be coated to stop them from drying and shedding their seal. The equipment perform of the fittings set up in the output shafts need an ISO H7 or h6 margin for the hollow shaft.

Our Organization

HANGZHOU Ever-Electricity Team, One OF THE Biggest GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Tools Supply STATION

Our business is situated in the metropolis of HangZhou, ZheJiang Province of China.

We take care of the items of electricity transmission, our lines largely go over sequence products in velocity reducers, gearboxes , linked electricial motors and other energy transmission add-ons. Based mostly on the flexible functions, our items can be used in several fields: machines of waste h2o treatment, dredgers, chemical market, cranes, metallic working mills, conveyors, paper market, cement sector, cableways and so on.With the superb quality and realistic cost , our goods take pleasure in a great reputation from clients and the friends all over the entire world.

Furthermore, the R&D investment decision are each year escalating for the goal of greater meeting the new calls for of our clients and adapting the new inclination of the market.

Depending on the concepts of actually running and mutual benefit, We sincerely search ahead to cooperating with you.

Application region

Certifications

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In purchase to ensure the integrity of merchandise look, we will decide on cartons, picket pallets and wooden pallets in accordance to client wants.

●Delivery time: Each and every reducer is made and tested in accordance with strict and mounted techniques to guarantee that the quality is proper just before leaving the manufacturing facility and delivery on time.

●Transportation manner: We will pick the most ideal method of transportation for our customers in accordance to the fat and dimension of the items. We can also decide on the method of transportation in accordance to the needs of our buyers.

●Receiving and following-product sales service: Following obtaining the goods, make sure you examine whether or not they are in great situation. We will supply consumers with excellent soon after-income services.

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a company in ZheJiang Province, China. Our firm owns the potential of producing, processing,designing and R&D. We welcome your check out.

Q2: How we pick designs and technical specs?

A: According to the specific information of the demands from the part of enquiry, we will advocate the products’ models on synthesizing the variables of discipline of products use, electrical power, torque arm and ratio…

Q3: How is your price tag? Can you offer any price cut?

A: Our rates are always aggressive. If the client can spot a large purchase, we absolutely will permit low cost.

This autumn: How lengthy should I wait for the suggestions soon after I send out the enquiry?

A4: We will reply the enquiries without any hold off, twelve hours at most.

Q5: What is your merchandise guarantee period of time?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes currently being utilised?

A: Our gearboxes are extensively utilized to metallurgical gear, mining equipment, automation equipment, foods equipment, packaging equipment, tobacco equipment and so on.

Scorching-sale Merchandise

Custom dc worm gear motor 12v near me made in China – replacement parts – in Mumbai India Drum Pinion Bevel Gear Set for Cement Concrete Mixer with top quality

We – EPG Group the biggest worm gearbox, couplings and gears manufacturing unit in China with 5 various branches. For far more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

Q:What`s the MOQ of your goods?

A:one established,we can also offer with the sample get. and the huge-quantity.

Q:How could i know if the merchandise suited for my machine?

A:Our sales will speak to with you to make certain the specific dimension,knowledge and other crucial information of your aimed products.We make positive all the goods fit for your device.

Q:I want to uncover a new provider for merchandise,can you?

A:Positive,we can offer the whole day services for your consulting,we purpose at currently being your most crucial supplier.

Q:What`s the payment terms of the order?

A:As your need,we can settle for several sorts of payment phrases.

/ The use of original tools manufacturer’s (OEM) element quantities or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our business and the detailed alternative parts contained herein are not sponsored, approved, or created by the OEM. /

AC wholesaler made in China – replacement parts – in Patiala India Shade Pole Gear Motor for Household Appliance with top quality

We – EPG Group the most significant gearbox & motors , couplings and gears manufacturing unit in China with 5 diverse branches. For much more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Description of the production

Suit for remotr check manage, distant curtain, electrical soldering, h2o meter, BBQ, oven, washing device, rubbish machines, residence appliances, slot device, income determine equipment, auto equipment.

Geared motor torque/speed

| Reduction ratio | one:251 | 1:389 | one:590 | one:722 | 1:897 | one:1269 | 1:1601 | 1:1929 | one:2708 | 1:3385 | 1:5078 |

| Quantity of gear trans | 4 | 5 |

6 |

||||||||

| Rated velocity(rpm) at 60Hz | eleven.1 | 7.one | 4.seven | three.8 | three.one | 2.2 | 1.seven | one.four | 1. | .8 | .five |

| YJ61-PAG70120 L=sixteen(kgf.cm) Rated torque |

22.eight | 35.four | fifty three.7 | 65.7 | eighty one.6 | 104 | 132 | 159 | 200 | 200 | 200 |

| YJ61-PAG70120 L=26(kgf.cm) Rated torque |

35.nine | fifty five.6 | 84.4 | 103 | 128 | 164 | two hundred | 200 | two hundred | two hundred | 200 |

| YJ61-PAG70120 L=30(kgf.cm) Rated torque |

forty five.seven | 70.8 | 107 | 131 | 163 | 200 | 200 | 200 | 200 | two hundred | two hundred |

| YJ61-PAG70120 L=35(kgf.cm) Rated torque |

fifty seven.one | 88.5 | 134 | 164 | 200 | two hundred | two hundred | two hundred | 200 | 200 | 200 |

| YJ61-PAG70120 L=forty(kgf.cm) Rated torque |

65.five | one zero one | 153 | 187 | 200 | two hundred | 200 | 200 | 200 | 200 | two hundred |

two.Generation Stream

3.Business Details

In recent 10 many years, ept has been committed to the manufacture of the motor items and the main merchandise can be categorised into the subsequent sequence, particularly DC motor, DC gear motor, AC motor, AC equipment motor, Stepper motor, Stepper gear motor, Servo motor and Linear actuator sequence.

Our motor products are widely applied in the fields of aerospace market, automotive sector, financial gear, house appliance, industrial automation and robotics, medical products, place of work gear, pac ept machinery and transmission market, supplying buyers reliable customized remedies for driving and controlling.

four.Our Companies

one). Basic Services:

| Rapid Reply | All enquiry or email be replied in twelve several hours, no hold off for your business. |

| Skilled Team | Questions about goods will be replied professionally, just, very best advice to you. |

| Quick Lead time | Sample or little buy sent in 7-fifteen times, bulk or custom-made buy about thirty days. |

| Payment Decision | T/T, Western Union,, L/C, and many others, simple for your organization. |

| Ahead of cargo | Take images, deliver to consumers for confirmation. Only verified, can be delivered out. |

| Language Choice | Aside from English, you can use your very own language by email, then we can translate it. |

2). Customization Services:

Motor specification(no-load speed , voltage, torque , diameter, noise, lifestyle, screening) and shaft size can be tailor-created according to customer’s needs.

5.Package deal & Shipping

The use of first products manufacturer’s (OEM) element figures or logos , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our company and the detailed replacement parts contained herein are not sponsored, accredited, or created by the OEM.

42mm factory made in China – replacement parts – in Zaria Nigeria Brushless DC Planetary Gear Motor with Built-in Driver with top quality

We – EPG Group the most significant gearbox & motors , couplings and gears manufacturing unit in China with 5 diverse branches. For much more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13 571 88828 13858117778 571 88828

42JX150K/42ZWNP59

3 period 10 poles brushless DC motor, with built-in driver

Brushless Gear Motor Technical Data

42ZWNP59-2440 BLDG Motor

| Reduction ratio | three.five | fourteen | 21 | forty nine | 84 | 104 | 126 | 172 | 294 |

| Amount of gear trains | 1 | 2 | 2 | three | three | three | three | 4 | four |

| (L) Length(L) mm | 32.5 | 39.two | 39.2 | forty six | forty six | 46 | 46 | 52.five | 52.five |

| No- load speed r/m n | 1143 | 286 | 190 | 82 | forty eight | 38 | 32 | 23 | 14 |

| Rated speed r/min | 857 | 214 | 143 | 61 | 36 | 29 | 24 | seventeen | ten |

| Rated torque N.m | .21 | .77 | 1.one | 2.four | four.1 | five.one | 6.two | 7.seven | thirteen |

| N.m Max. permissible load in a quick time |

three | 12 | 12 | twenty five | twenty five | 25 | twenty five | 30 | 30 |

Wire Diagram

| + Stage V |

– Section W |

Reversing |

Pace Handle |

Braking | +5V Out place |

Pulse Output |

| Crimson |

Black | Brown | Orange | White | Eco-friendly | Blue |

B-5

| Proportions (mm) | Rated Voltage (V) |

Rated Speed ( r/min ) |

Reduction Ratio | Rated Torgue (N.m) |

| 22 | 12~24 | 3500 | one:3.7-1:51 | .073-.80 |

| 28 | 12~24 | 2000-3700 | 1:3.7-1:720 | .017-3. |

| 32 | 12~24 | 7800 | one:3.7-1:369 | .073-3. |

| 36 | twelve~24 | 2100-2800 | 1:3.7-1:369 | .09-3. |

| 37 | twelve~24 | 1400-2800 | one:21.5-1:250 | .07-3. |

| forty two | 12~24 | 1400-3000 | 1:3.5-1:944 | .12-20. |

| fifty six | twelve~24 | 1200-2000 | one:3.6-1:326 | .27-eighteen. |

| sixty | 12~24 | 1300-2250 | one:3-1:ninety | .20-1.5. |

Characteristics:

The planetary gearbox for transmission is commonly matched with DC motor and BLDC motor. It exhibits the characters of high torque and controlablity as properly as the large long lasting torque. The excellent blend fully expresses the product’s scaled-down and substantial torque.

Packaging & Shipping:

1, Waterproof plastic bag packed in foam box and carton as outer packing.

two, Export wooden box packaging for products.

WHY Picking US:

- Open up for common discussion and inquiries

- Time to industry or theatre of functions can be significantly reduced

- Proficient team of engineers offering modern technological answers

- 1 stop “provider” and complete sub-program

- Top quality goods offered at aggressive reduced cost

- Ability to ship planet broad

- On time delivery

- Education at Consumer locations

- Fast service on return and mend final results

- Many recurring clients

The use of first gear manufacturer’s (OEM) component quantities or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our organization and the listed substitute areas contained herein are not sponsored, approved, or manufactured by the OEM.

Best China manufacturer & factory S in Hyderabad Pakistan series helical worm gear reducer bevel gear reducer stepper motor helical gear box drive reducer friction gearbox With high quality best price

More importantly, we make specific parts in accordance to provided drawings/samples and warmly welcome OEM inquiries. Close up of two yokes with the common joint. Note the slight oozing of grease from the UJ seal ends, the clump of grease is from inside the yoke splined shaft spot –Push (outer) yoke has a woman (usual spline) gap and “Y” condition end that is the universal joint (UJ) mount. –UJ is a cross formed casting obtaining roller bearings enclosed with caps at all four points and is held into the yoke with four “C” clips –Inner yoke and drive shaft is yet another yoke welded to the drive finish, of the drive shaft. –Driven shaft and inner yoke is the pushed shaft that rides inside of the drive shaft and has a yoke welded at the driven conclude –UJ yet another UJ as previously mentioned

Overview

Swift Particulars

- Applicable Industries:

-

Lodges, Garment Stores, Creating Content Outlets, Manufacturing Plant, Machinery Repair Retailers, Food & Beverage Manufacturing unit, farms, restaurant, House USE, Retail, Meals Shop, Printing Outlets, Energy & Mining, Food & Beverage Retailers, Advertising and marketing Firm, Development performs

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

worm

- Output Torque:

-

one hundred~62800N.m

- Input Velocity:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

7.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC,ZWZ

Provide Capability

- Source Ability:

- 3000 Device/Units for each Thirty day period

Packaging & Supply

- Packaging Particulars

- Wood packing containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

On the web Customization

Solution Description

S collection is one variety of Helical worm gearbox ,made as Modularization and higher-stainless forged iron case . It is blend of helical gear and worm equipment ,which with greater efficiency and strength than straightforward aluminum worm gearbox . Thanks to their excellent performance, these drives can be utilized in every single industrial sector and customized to specific torque and speed demands. The equipment ratios afforded by the helical-worm gear phase and the low sounds ranges during operation make these gearmotors ideal reduced-expense options for basic programs

Requirements:

one) Output velocity: .6~1,028r/min

2) Output torque: up to 4530N.m

three) Motor electrical power: .12~22kW

four) Mounted type: foot-mounted and flange-mounted mounting

|

Merchandise Name |

SLS Series helical-Worm reducer |

|

Equipment Substance |

20CrMnTi |

|

Case Content |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding end by HOFLER Grinding Equipment |

|

Color |

Customized |

|

Sounds Test |

Bellow 65dB |

|

Machining precision of gears |

accurate grinding, 6 Quality |

|

Heat treatment method |

tempering, cementiting, quenching,and so on. |

|

Manufacturer of bearings |

C&U ,HRB,LYC,ZWZ.SKF,NSK |

|

Model of oil seal |

NAK or other brand name |

|

Noise (MAX) |

sixty five~70dB |

|

Temp. increase (MAX) Another edge of worm gears is that they have very good meshing performance. To be most effective, it is essential that they are manufactured with large top quality requirements to make certain all equipment specifications are precisely met. |

forty C |

|

Temp. rise (Oil)(MAX) |

fifty C |

Certifications

Trade Shows

Packaging & Delivery

Packing Particulars : Standard carton/Pallet/Standard wooden case

Shipping and delivery Information : 15-thirty operating times on payment

Business Info

other series solution

| Precision Planetary gearbox | Robotic RV gearbox speed reducer |

| CuEPG Machinery is found in XiHu Location HangZhou Zhejiang ,China. It is 30km from our manufacturing facility to HangZhou worldwide airport. stom manufactured Non-regular Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Collection Substantial Energy Reducer |

| NMRV Sequence Worm Reducer | BKM Sequence Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Relevant Items

Get in touch with

Gears Cost made in China – replacement parts – in Wroclaw Poland and Gear Shaft Used for Wood WorEPT Machine Motor with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 distinct branches. For a lot more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product Description

Xihu (We EPT Lake) Dis.g Large Precision Personalized Equipment Shaft

The shaft is a kind of mechanical transmission, which transmits mechanical torque. There is a longitudinal keyway on the outer floor of the shaft, and the rotating member sleeved on the shaft also has a corresponding keyway, which can keep rotating synchronously with the shaft. Although rotating, some can also slide longitudinally on the shaft, this kind of as gearbox shifting gears.

We can make customers’ satisfactory merchandise in accordance to the samples or drawings supplied by customers. For the completion of a product, we also need to have to know his materials, heat treatment needs and surface area treatment requirements. We are a manufacturing unit with forty years of manufacturing experience, welcome to consult.

The gain of our shaft

one Higher carrying ability

two Excellent orientation

three Small stress focus

four Practical processing, substantial precision with grinding method

5 High strength and long existence

HangZhou Xihu (We EPT Lake) Dis.g EPT EPT Co., Ltd. is a specialised provider of a complete variety of motor shafts, gears, Flanges(Couplings), equipment racks, sprockets, pulley, machined parts and so on.

Due to our sincerity in offering be EPT provider to our clients, comprehension of your needs and overriding perception of obligation towards filling buying needs, we have acquired the tru EPT of consumers throughout the world. Getting accrued precious expertise in cooperating with overseas customers, our products are promoting properly in the American, European, South American and Asian markets.Our products are manufactured by contemporary computerized equipment and equipment. In the meantime, our goods are made according to substantial high quality specifications, and complying with the worldwide superior common standards.

With a lot of years’ encounter in this line, we will be reliable by our benefits in aggressive cost, one-time delivery, prompt reaction, on-hand engineering assist and great right after-product sales services.

Furthermore, we also can design and make non-regular products to fulfill customers’ unique needs. Quality and credit are the bases that make a company alive. We will provide be EPT services and large good quality items with all sincerity. If you need to have any details or samples, please speak to us and you will have our shortly reply.

FAQ

one)Are you investing company or producer?

We are factory.

two)How can I personalize my merchandise?

Attach your drawing with information(area remedy,materials,amount and special needs and many others.)

three)How lengthy can I get the quotation?

We will give you the quotation within forty eight several hours(thinking about the time difference)

4)How extended will you generate the elements?

Typically it is 5-ten days if the merchandise are in stock. Or it is fifteen-25 days if the products are not in stock, it really is in accordance to quantity.

5)Do you offer samples? Is it free of charge or further?

Yes, we could supply the sample, the samples and shipping fees require to be borne by the customer.

six)What is your phrases of payment?

Payment≤1000 USD, one hundred% in advance. Payment≥1000 USD, thirty% T/T in progress, stability ahead of shipment. If you have any queries, please do not be reluctant to speak to us.

7)What if the merchandise we gained are not great?

Get in touch with us with no hesitation, our particular soon after-sales support will take the responsibility.

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For much more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original gear manufacturer’s (OEM) element quantities or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating solution use and compatibility. Our company and the detailed alternative areas contained herein are not sponsored, authorized, or produced by the OEM.

Helical near me made in China – replacement parts – in Mosul Iraq Gear Single Phase Right Angle AC Brake Gear Motor for Transmission Brushless with top quality

We – EPG Group the biggest gearbox & motors , couplings and gears manufacturing unit in China with 5 different branches. For much more information: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

RODUCT FATUERS:

The business is a specialised factory that creates miniature equipment reduction motors on a fastened-position basis. It has a generation history of a lot more than ten years. The organization has a complete established of business management and technical administration programs, and its goods are made in strict accordance with GB / T19001-2000 expectations.

The “Weiqiang” gear reducer made by our business sells nicely in provinces, municipalities and autonomous areas of the region. It is extensively utilised in metallurgy, mining, lifting, transportation, petroleum, chemical, textile, pharmaceutical, foods, gentle sector, grain, oil, feed and other industries, and is deeply reliable by clients.

Welcome new and aged buyers to visit and guide.

Packaging & Shipping:

1, Waterproof plastic bag packed in foam box and carton as outer packing.

two, Export wooden box packaging for products.

The use of original products manufacturer’s (OEM) component numbers or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating product use and compatibility. Our organization and the listed substitution elements contained herein are not sponsored, authorized, or created by the OEM.

S 3hp electric motor single phase Custom made in China – replacement parts – in Izhevsk Russian Federation Series Helical Gear Worm Reducer with top quality

We – EPG Team the most significant worm gearbox, couplings and gears factory in China with 5 different branches. For far more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

S Collection Helical-Worm Reduction Gearbox

1. Product Qualities:

S sequence helical worm gearbox adopts the helical worm gears to make its framework much more realistic. S series not only has larger transmission efficency and loading functionality than people single-phase worm wheel transmission, but also smaller quantity and visual appeal. Furthermore, S collection worm gearbox has increased transmission ratio, and can be blended with different gearboxes and speed variators to satisfy the distinct requirements.

2. Structure:

S series gearbox are offered in the adhering to types:

(1) SY Foot mounted helical worm gearbox with sound shaft

(2) SAY Helical worm gearbox with hollow shaft

(3) SAZY Small flange mounted helical worm gearbox with hollow shaft

(4) SA (S,SF,SAF,SAZ)Y Assemble users’ motor or particular motor, flange is essential

(5) SFY Flange mounted helical worm gearbox with strong shaft

(6) SAFY Flange mounted helical worm gearbox with hollow shaft

(7) SATY Torque arm mounted helical worm gearbox with hollow shaft

(8) S (SF,SA,SAF,SAZ) S Shaft enter helical worm gearbox

(9) SA (S,SF,SAF,SAZ)RY Combined helical worm gearbox

(ten) SA (S,SF,SAF,SAZ)SR Shaft input combined helical worm gearbox

three. Thorough parameters:

| Size |

38 | forty eight | 58 | 68 | 78 | 88 | ninety eight |

| Construction |

S SA SF SAF SAT SAZ | ||||||

| Input Electrical power(KW) | .eighteen-.75 | .eighteen-1.five | .eighteen-three | .twenty five-5.five | .fifty five-7.five | .seventy five-15 | one.5-22 |

| Ratio | ten.27-152 | 11.forty six-244.seventy four | ten.seventy eight-196.21 | 11.55-227.20 | nine.96-241.09 | 11.83-222 | twelve.75-230.48 |

| Maximum torque(N.m) | 90 | 170 | 295 | 520 | 1270 | 2280 | 4000 |

four.Applications:

The merchandise are commonly applied in electrical energy, coal, cement, metallurgy, harbor, agriculture, delivery, lifting, setting protection, stage, logistic, weaving, paper making, light market, plastics and other areas.

five. Complex Info:

Rated Energy:.18~22KW

Output Pace: 0.16~147r/min

Output Torque:ninety~4000N.m

Mounted Type:Foot-mounted, flange mounted, shaft-mounted, torque arm mounted

6.Solution image:

Deals:

Company Info:

Speak to Information:

/ The use of authentic tools manufacturer’s (OEM) component quantities or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our organization and the shown substitute components contained herein are not sponsored, authorized, or made by the OEM. /