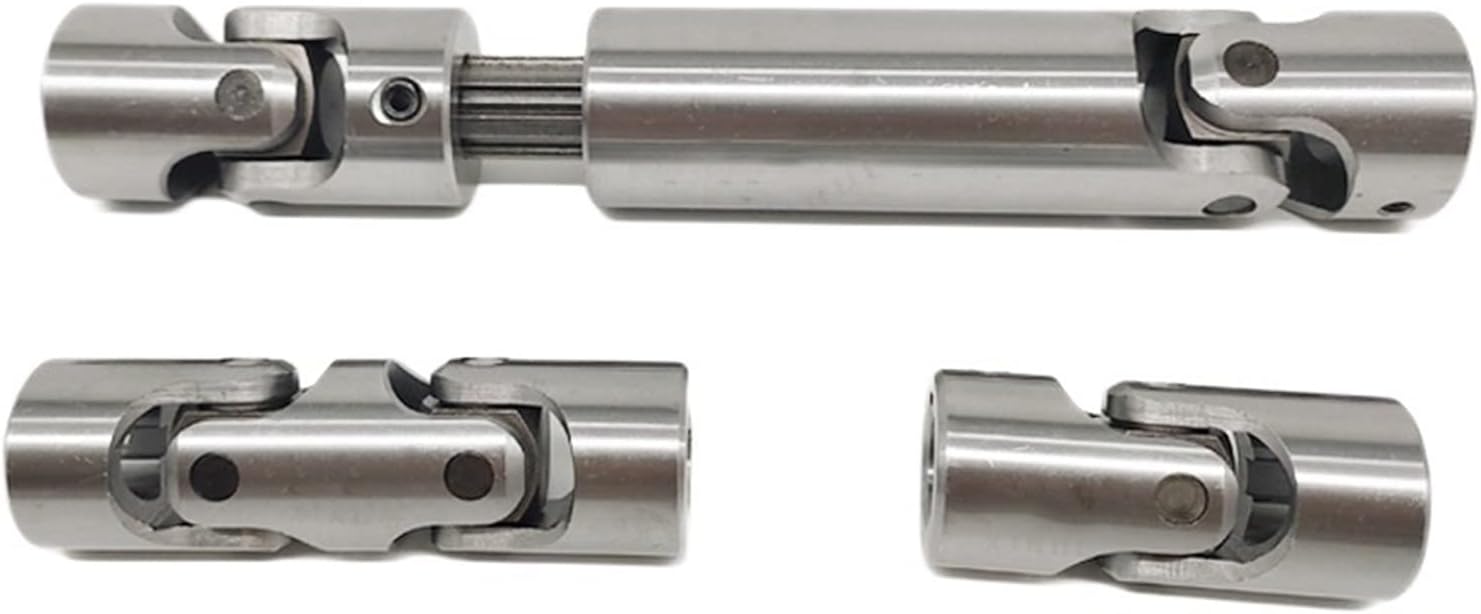

Introducing Cardan Coupling for Leather Processing Machines

Keyword Content:

- Cardan coupling

- Leather processing machines

- High quality

- Low price

- Customizable

- Reliable performance

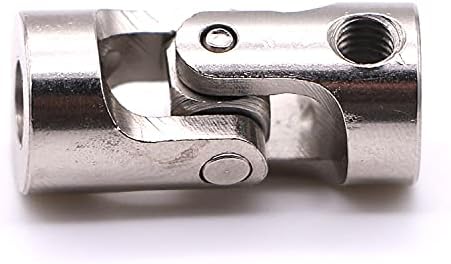

What is Cardan Shaft Coupling?

1. Mechanism:

A Cardan shaft coupling consists of a shaft with universal joints at each end to allow for misalignment between the driving and driven components.

2. Application:

It is commonly used in leather processing machines to transmit power efficiently and smoothly.

3. Benefits:

Cardan couplings are known for their high quality, durability, and reliable performance, making them ideal for industrial applications.

4. Customization:

These couplings can be customized to fit specific requirements of leather processing machines, ensuring a perfect fit.

5. Cost-Effective:

Despite their superior quality, Cardan shaft couplings are offered at a competitive price, making them a cost-effective solution for businesses.

What is the Purpose of a Cardan Shaft?

1. Power Transmission:

A Cardan shaft is designed to transmit power from the engine to the wheels or other driven components, allowing for smooth operation.

2. Misalignment Compensation:

It helps to compensate for misalignment between the driving and driven components, reducing wear and tear on the machinery.

3. Flexibility:

The flexibility of a Cardan shaft allows for smooth operation even in challenging working conditions, such as in leather processing machines.

4. Torque Transmission:

These shafts are capable of transmitting high torque loads, making them suitable for heavy-duty industrial applications.

5. Vibration Dampening:

Cardan shafts help to dampen vibrations, resulting in smoother operation and reduced stress on the machinery.

What is the Purpose of a Double Cardan Joint?

1. Increased Range of Motion:

Double Cardan joints allow for a greater range of motion compared to single universal joints, making them ideal for applications with significant misalignment.

2. Improved Efficiency:

These joints help to reduce power loss and increase efficiency in power transmission systems, ensuring optimal performance.

3. Enhanced Durability:

Double Cardan joints are known for their durability and reliability, making them suitable for heavy-duty applications in leather processing machines.

4. Reduced Maintenance:

Due to their design and construction, double Cardan joints require less maintenance and have a longer service life compared to other types of joints.

5. Smooth Operation:

These joints provide smooth and consistent operation, even under high loads and challenging working conditions, ensuring reliable performance.

How to Choose the Appropriate Cardan Coupling

1. Consider the Application:

Identify the specific requirements of the leather processing machine and choose a Cardan coupling that can meet those needs effectively.

2. Evaluate Load Capacity:

Determine the maximum torque and power transmission requirements of the machinery to select a coupling with the appropriate load capacity.

3. Check for Misalignment:

Assess the degree of misalignment between the driving and driven components to choose a coupling that can compensate for it efficiently.

4. Quality and Reliability:

Ensure that the Cardan coupling is of high quality, durable, and reliable to guarantee long-term performance and minimal downtime.

5. Customization Options:

Look for couplings that offer customization options to tailor the product to the specific needs of the leather processing machines, ensuring a perfect fit.

What is the Difference Between a Disc and a Cardan Coupling?

1. Mechanism:

Disc couplings use flexible discs to transmit torque, while Cardan couplings use universal joints for power transmission.

2. Misalignment Compensation:

Cardan couplings can accommodate greater misalignment compared to disc couplings, making them more suitable for applications with significant alignment issues.

3. Load Capacity:

Cardan couplings are capable of transmitting higher torque loads compared to disc couplings, making them ideal for heavy-duty industrial applications.

4. Maintenance:

Disc couplings require less maintenance compared to Cardan couplings, as they have fewer moving parts and are less prone to wear and tear.

5. Cost:

Cardan couplings are generally more cost-effective than disc couplings, offering a balance between performance and affordability for businesses.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in couplings for various industries, including leather processing machines. With 16 years of experience, we offer high-quality products, competitive prices, and customization options to meet the unique needs of our customers. Our commitment to customer satisfaction and product excellence has earned us a strong reputation in Europe and the United States. Choose HZPT for reliable performance, exceptional service, and superior quality couplings for your machinery needs.