Introducing Cardan Coupling for Dyeing Machines

Keyword Content:

- What is Cardan shaft coupling?

- What is the purpose of a Cardan shaft?

- What is the purpose of a double cardan joint?

- How to choose the appropriate cardan coupling?

- What is the difference between a disc and a cardan coupling?

- About HZPT

What is Cardan Shaft Coupling?

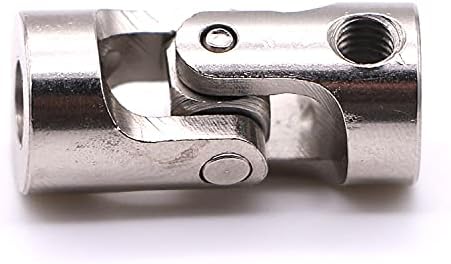

- Cardan shaft coupling, also known as universal joint shaft, is a mechanical component used to transmit torque between two shafts that are not in line with each other.

- It consists of a cross-shaped piece with needle bearings at each end connected to shafts, allowing for flexibility and torque transmission at various angles.

- Cardan shaft couplings are commonly used in machinery, especially in dyeing machines, for their ability to transmit power efficiently even when shafts are misaligned.

- These couplings are essential for maintaining smooth operation and preventing damage to machinery components.

- Cardan shaft couplings are durable, reliable, and easy to install, making them a popular choice for industrial applications.

What is the Purpose of a Cardan Shaft?

- Transmitting power between two shafts at angles.

- Allowing for flexibility and misalignment compensation.

- Providing smooth torque transmission even under harsh conditions.

- Preventing damage to machinery components by absorbing shock and vibration.

- Enhancing overall efficiency and performance of machinery systems.

What is the Purpose of a Double Cardan Joint?

- Increased angular flexibility and reduced vibration.

- Improved torque transmission and power efficiency.

- Enhanced durability and reliability in heavy-duty applications.

- Reduced maintenance and downtime due to superior performance.

- Optimized operation and longevity of machinery systems.

How to Choose the Appropriate Cardan Coupling?

- Consider the torque and power requirements of the machinery.

- Evaluate the angle and misalignment between shafts.

- Choose the right size and material for optimal performance.

- Ensure compatibility with existing machinery components.

- Consult with experts to determine the best fit for your specific application.

What is the Difference Between a Disc and a Cardan Coupling?

- Cardan couplings offer greater angular flexibility compared to disc couplings.

- Disc couplings provide higher torsional stiffness for precision applications.

- Cardan couplings are more cost-effective and easier to install than disc couplings.

- Disc couplings offer better misalignment compensation and vibration damping.

- Each type of coupling has its advantages and is suitable for different applications based on specific requirements.

About HZPT

Our company, HZPT, established in 2006, specializes in designing, developing, and producing high-quality couplings for various industries, including dyeing machines. With 16 years of expertise, we offer customization, rigorous quality control, and excellent customer service to ensure satisfaction. Our commitment to quality, reputation, and competitive pricing makes us the preferred choice for customers in Europe and the United States. Partner with HZPT for reliable products and exceptional service.