Introducing Cardan Coupling for Laboratory Instruments

When it comes to laboratory instruments, having reliable and efficient components is crucial for accurate results. One such essential component is the Cardan coupling, designed to provide smooth and flexible power transmission. Let’s delve into the details of what makes the Cardan coupling ideal for laboratory instruments:

1. High-Quality Materials

The Cardan coupling for laboratory instruments is crafted from premium materials, ensuring durability and longevity even in demanding laboratory settings. The use of high-quality materials guarantees smooth operation and minimal maintenance requirements.

2. Precision Engineering

Each Cardan coupling is meticulously engineered to deliver precise and reliable power transmission. The precision design of the coupling ensures minimal energy loss and maximum efficiency, making it perfect for laboratory instruments that require accuracy.

3. Flexibility and Versatility

Cardan couplings for laboratory instruments are known for their flexibility and versatility. They can accommodate misalignments and angular deflections, allowing for seamless operation even in confined laboratory spaces.

4. Easy Installation and Maintenance

Installing and maintaining a Cardan coupling for laboratory instruments is a breeze. With simple assembly procedures and minimal maintenance requirements, these couplings are designed for hassle-free operation, saving time and effort in the laboratory.

5. Enhanced Performance

The Cardan coupling enhances the performance of laboratory instruments by providing smooth and reliable power transmission. Its efficient design minimizes vibrations and noise, ensuring precise results in laboratory experiments and tests.

6. Cost-Effective Solution

Investing in a Cardan coupling for laboratory instruments is a cost-effective solution in the long run. Its durable construction and efficient performance translate to lower maintenance costs and extended service life, making it a valuable addition to any laboratory.

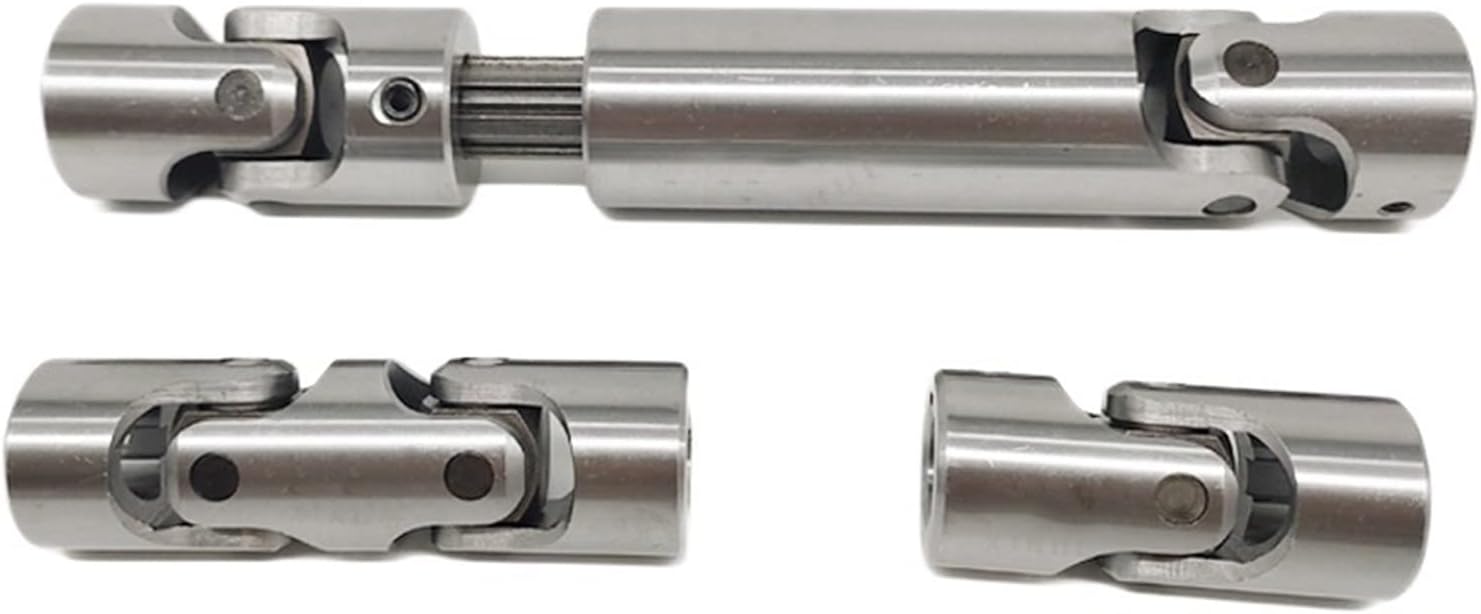

What is Cardan Shaft Coupling?

A Cardan shaft coupling, also known as a universal joint, is a mechanical component used to transmit power between shafts that are not in a straight line. It consists of two yokes connected by a cross-shaped intermediate component, allowing for angular misalignment and smooth power transmission. The key aspects of Cardan shaft couplings include:

1. Flexibility

Cardan shaft couplings offer flexibility by accommodating angular misalignments between shafts, ensuring smooth power transmission even in non-linear configurations.

2. Torque Transmission

These couplings are designed to transmit torque between shafts efficiently, minimizing energy loss and maximizing power delivery in various industrial applications.

3. Vibration Dampening

Cardan shaft couplings help dampen vibrations and reduce noise levels during operation, contributing to a quieter and more stable working environment.

4. Maintenance-Free Operation

With minimal moving parts and sturdy construction, Cardan shaft couplings require little to no maintenance, ensuring reliable performance over an extended period.

5. Versatile Applications

From automotive to industrial machinery, Cardan shaft couplings find applications in a wide range of industries, thanks to their versatility and compatibility with different shaft configurations.

What is the Purpose of a Cardan Shaft?

A Cardan shaft, also known as a propeller shaft or drive shaft, serves several essential purposes in various mechanical systems:

1. Power Transmission

The primary purpose of a Cardan shaft is to transmit power from the engine to the wheels or other driven components in vehicles, machinery, and industrial equipment.

2. Angular Misalignment Compensation

Cardan shafts accommodate angular misalignments between driving and driven shafts, ensuring smooth power transmission even when the shafts are not in a straight line.

3. Vibration Reduction

By transmitting torque smoothly and efficiently, Cardan shafts help reduce vibrations and noise levels, improving the overall comfort and performance of the system.

4. Length Adjustment

Cardan shafts can adjust in length to accommodate changes in the distance between driving and driven components, providing flexibility in various mechanical setups.

5. Versatile Applications

From automotive drivetrains to industrial machinery, Cardan shafts play a crucial role in power transmission and system functionality across different industries and applications.

What is the Purpose of a Double Cardan Joint?

A Double Cardan joint, also known as a constant-velocity joint, serves several key purposes in driveshaft systems:

1. Smooth Power Transmission

Double Cardan joints provide constant velocity and smooth power transmission between driving and driven shafts, reducing vibrations and energy loss in the system.

2. Angular Misalignment Compensation

These joints accommodate angular misalignments in multiple directions, ensuring efficient power transfer even in complex drivetrain configurations.

3. Vibration Dampening

By maintaining constant velocity and minimizing variations in rotational speed, Double Cardan joints help dampen vibrations and improve system stability during operation.

4. Enhanced Durability

Double Cardan joints are designed for high durability and reliable performance, making them ideal for demanding applications in automotive, industrial, and off-road settings.

5. Versatile Applications

From off-road vehicles to heavy machinery, Double Cardan joints find applications in various drivetrain systems that require constant velocity and smooth power transmission across different angles and configurations.

How to Choose the Appropriate Cardan Coupling

Choosing the right Cardan coupling for your specific application requires careful consideration of several key factors:

1. Load Capacity

Consider the maximum torque and load requirements of your application to ensure the Cardan coupling can handle the intended workload without compromising performance.

2. Operating Speed

Take into account the rotational speed of the shafts to select a Cardan coupling that can operate efficiently at the required speeds without causing vibrations or energy loss.

3. Misalignment Tolerance

Determine the degree of angular misalignment between shafts in your system and choose a Cardan coupling that can accommodate the specified misalignment without affecting power transmission.

4. Environmental Conditions

Evaluate the operating environment, including temperature, humidity, and exposure to chemicals or contaminants, to select a Cardan coupling with the appropriate corrosion resistance and durability.

5. Installation and Maintenance

Consider the ease of installation and maintenance requirements of the Cardan coupling to ensure smooth operation and minimal downtime in your application.

What is the Difference Between a Disc and a Cardan Coupling?

Disc and Cardan couplings are two common types of flexible couplings used in various applications. Here are the key differences between the two:

1. Design

Disc couplings consist of flexible discs that accommodate misalignments, while Cardan couplings use universal joints to transmit power between shafts at angles.

2. Misalignment Compensation

Disc couplings are limited in their angular misalignment capacity compared to Cardan couplings, which can accommodate more significant misalignments in multiple directions.

3. Torque Transmission

Cardan couplings are more efficient in transmitting torque between shafts, making them suitable for high-torque applications compared to disc couplings.

4. Applications

Disc couplings are commonly used in light to moderate-duty applications, while Cardan couplings are preferred for heavy-duty industrial and automotive applications that require robust power transmission.

5. Maintenance Requirements

Cardan couplings generally have lower maintenance requirements compared to disc couplings, thanks to their sturdy construction and efficient power transmission design.

About HZPT

At HZPT, we specialize in designing, developing, and producing high-quality couplings for various industries, including laboratory instruments. With over 16 years of experience, our company prides itself on providing customized solutions to meet the unique needs of our global customers.

Our commitment to quality and customer satisfaction drives us to deliver reliable products with CE and TUV certifications. We offer 24/7 customer service, ensuring that any issues or inquiries are promptly addressed. With competitive pricing and OEM/OEM capabilities, HZPT is your trusted partner for premium couplings.

Choose HZPT for unparalleled quality, exceptional service, and innovative coupling solutions that meet the highest industry standards. Join our growing list of satisfied customers in Europe and the United States and experience the difference that HZPT couplings can make in your applications.