Introduction to Cardan Coupling for Mattress Manufacturing Equipment

When it comes to ensuring smooth and efficient operation of mattress manufacturing equipment, the use of a reliable Cardan coupling is essential. This crucial component plays a key role in connecting various parts of the machinery, allowing for seamless power transmission and rotational movement. Let’s delve into the specifics of Cardan couplings and their significance in the mattress manufacturing industry.

What is Cardan Shaft Coupling?

1. Definition

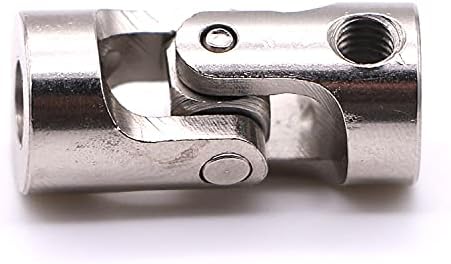

A Cardan shaft coupling, also known as a universal joint coupling, is a mechanical device used to transmit torque between two shafts that are not in line with each other. This flexible coupling allows for angular misalignment while maintaining continuous power transmission.

2. Structure

The Cardan coupling consists of a cross-shaped center piece with four arms connected to two shafts. It is designed to accommodate varying angles and distances between the shafts, providing flexibility and smooth operation.

3. Function

The primary function of a Cardan shaft coupling is to transfer rotational movement and torque from one shaft to another, even when they are misaligned. This helps prevent damage to the machinery and ensures efficient performance.

4. Applications

Cardan couplings are commonly used in various industries, including automotive, aerospace, and manufacturing. In the mattress manufacturing industry, these couplings are essential for connecting different components of the equipment, such as conveyor belts and cutting tools.

5. Benefits

Some of the key benefits of using Cardan shaft couplings in mattress manufacturing equipment include improved flexibility, reduced vibration, and enhanced durability. These couplings help optimize the performance of the machinery and minimize downtime.

What is the Purpose of a Cardan Shaft?

1. Torque Transmission

A Cardan shaft is designed to transmit torque between two shafts that are not collinear. This allows for the power to be transferred efficiently, even in cases of misalignment.

2. Flexibility

By accommodating angular misalignment, Cardan shafts provide flexibility in the operation of machinery, reducing stress on the components and enhancing overall performance.

3. Smooth Operation

With the ability to transfer rotational movement seamlessly, Cardan shafts contribute to the smooth operation of mattress manufacturing equipment, ensuring consistent output quality.

4. Misalignment Compensation

Cardan shafts are capable of compensating for misalignments between shafts, preventing potential damage and prolonging the lifespan of the machinery.

5. Versatility

Due to their versatile nature, Cardan shafts are suitable for a wide range of applications in the mattress manufacturing industry, offering reliability and efficiency in power transmission.

What is the Purpose of a Double Cardan Joint?

Double Cardan joints, also known as constant velocity joints, serve a specific purpose in transmitting torque and rotational movement in a more uniform manner compared to single Cardan joints. These components are commonly used in applications where smooth and constant power transmission is required, such as in high-speed machinery and vehicles.

How to Choose the Appropriate Cardan Coupling

When selecting a Cardan coupling for mattress manufacturing equipment, it is essential to consider several key factors to ensure optimal performance and longevity. Here are some important points to keep in mind:

1. Load Capacity

Ensure that the Cardan coupling can handle the specific load requirements of the mattress manufacturing equipment, taking into account factors such as torque and rotational speed.

2. Size and Compatibility

Choose a Cardan coupling that is compatible with the shaft sizes and dimensions of the equipment, ensuring a proper fit and secure connection.

3. Material Quality

Opt for a Cardan coupling made from high-quality materials that can withstand the rigors of continuous operation and provide long-lasting performance.

4. Maintenance Requirements

Consider the maintenance needs of the Cardan coupling, selecting a model that is easy to maintain and repair to minimize downtime and ensure smooth operation.

5. Cost-Effectiveness

Weigh the cost of the Cardan coupling against its quality and features, choosing a product that offers the best value for your investment in terms of performance and durability.

What is the Difference Between a Disc and a Cardan Coupling?

When comparing disc couplings and Cardan couplings, there are several key differences to consider in terms of design, function, and applications. Let’s explore the distinctions between these two types of couplings:

1. Design

Disc couplings consist of flexible discs that connect the shafts, while Cardan couplings feature a cross-shaped center piece with multiple arms for torque transmission.

2. Flexibility

Disc couplings offer higher torsional stiffness and precision alignment, whereas Cardan couplings provide greater angular misalignment capacity and flexibility.

3. Torque Transmission

Cardan couplings are more suitable for transmitting high torque loads and compensating for misalignments, while disc couplings excel in applications requiring high-speed and low torque transmission.

4. Maintenance

Disc couplings are generally easier to maintain and require less frequent lubrication compared to Cardan couplings, making them a preferred choice for some industries.

5. Applications

Disc couplings are commonly used in precision machinery and high-speed applications, while Cardan couplings are preferred for heavy-duty industrial equipment and machinery with angular misalignment requirements.

About HZPT

As a leading manufacturer and exporter of couplings, HZPT has been providing high-quality products and exceptional service to customers in Europe and the United States for over 16 years. Our commitment to customer satisfaction and product excellence sets us apart in the industry. With a focus on quality, innovation, and customization, we strive to meet the unique needs of our clients and exceed their expectations. Choose HZPT for reliable couplings and superior performance in your machinery applications.