Introduction to Cardan Coupling for Blenders

Keyword Content:

- Cardan coupling

- Blenders

- Product design

- Functionality

- Customization

- Quality assurance

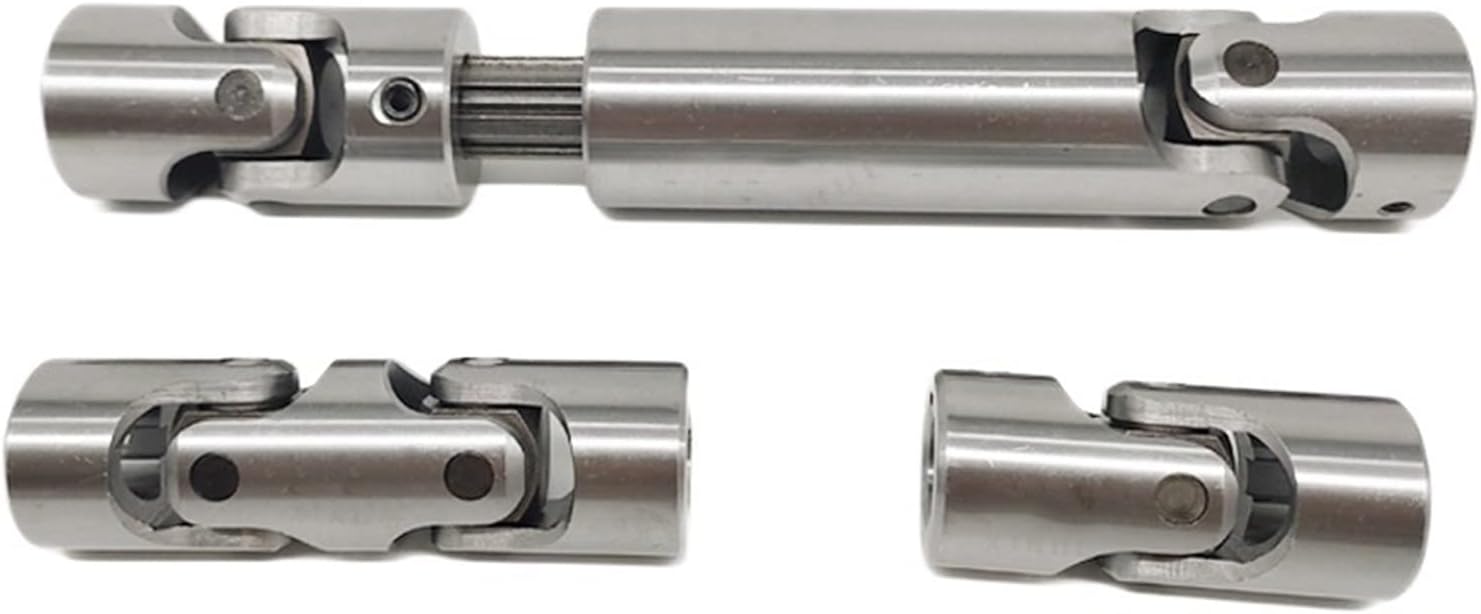

What is Cardan Shaft Coupling?

- Definition: A Cardan shaft coupling is a mechanical device used to transmit torque between two shafts that are not collinear. It consists of a cross-shaped joint and two shafts connected by it.

- Construction: The coupling is typically made of high-quality steel or alloy materials to ensure durability and strength.

- Benefits: It allows for the transmission of power at various angles and can accommodate misalignments between the shafts.

- Applications: Cardan shaft couplings are commonly used in industrial machinery, automotive applications, and other equipment that require torque transmission.

- Maintenance: Regular inspection and lubrication are essential to ensure the smooth operation and longevity of the coupling.

What is the Purpose of a Cardan Shaft?

- Power Transmission: The primary function of a Cardan shaft is to transmit rotational power between shafts that are not aligned.

- Flexibility: It allows for variable angles between the shafts, accommodating misalignments and vibrations.

- Reduced Wear: By absorbing shocks and vibrations, the Cardan shaft helps reduce wear and tear on connected components.

- Smooth Operation: It ensures a smooth and continuous power transfer, enhancing the overall efficiency of the machinery.

- Versatility: Cardan shafts are versatile and can be used in a wide range of applications across different industries.

What is the Purpose of a Double Cardan Joint?

- Enhanced Angular Movement: The double Cardan joint allows for increased angular movement compared to a single joint, making it suitable for applications with greater flexibility requirements.

- Reduced Vibration: It helps minimize vibrations and noise during operation, contributing to a smoother and quieter performance.

- Improved Durability: The double Cardan joint is designed to withstand higher loads and torque, providing enhanced durability in demanding applications.

- Precision: It offers precise power transmission, ensuring accurate alignment and consistent performance under varying conditions.

- Compatibility: The double Cardan joint can be used in conjunction with other shaft components to create complex power transmission systems.

How to Choose the Appropriate Cardan Coupling

- Consider the Application: Determine the specific requirements of your blending equipment and select a Cardan coupling that can meet the torque and alignment needs.

- Material Selection: Choose a coupling made of high-quality materials such as stainless steel or alloy to ensure durability and longevity.

- Size and Design: Select a coupling size and design that is compatible with your blender shafts and can accommodate any required misalignments.

- Customization Options: Look for manufacturers that offer customization options to tailor the coupling to your specific blending machine requirements.

- Quality Assurance: Ensure that the Cardan coupling undergoes rigorous testing and quality checks to guarantee reliable performance and safety in your blending operations.

What is the Difference Between a Disc and a Cardan Coupling?

- Construction: A disc coupling consists of a series of thin metal discs stacked together, while a Cardan coupling features a cross-shaped joint connecting two shafts.

- Flexibility: Disc couplings offer limited angular movement compared to Cardan couplings, which can accommodate greater misalignments.

- Applications: Disc couplings are commonly used in high-speed applications, while Cardan couplings are suitable for variable angle transmission requirements.

- Damping Characteristics: Disc couplings provide better damping of vibrations, whereas Cardan couplings are more versatile in handling misalignments.

- Installation: Disc couplings require precise alignment during installation, whereas Cardan couplings offer more flexibility in alignment requirements.

About HZPT

Our company, HZPT, established in 2006, specializes in designing, developing, and producing high-quality couplings for various industrial applications. With 16 years of experience, we offer customization options, rigorous quality checks, and excellent customer service. Our products, including radial elastic couplings, drum gear couplings, and more, are trusted by customers in Europe and the United States for their reliability and performance. Choose HZPT for the best in coupling technology and service excellence.