Introduction to Cardan Coupling for Motion Control Systems

Keyword Content:

- What is Cardan shaft coupling?

- What is the purpose of a Cardan shaft?

- What is the purpose of a double cardan joint?

- How to choose the appropriate cardan coupling?

- What is the difference between a disc and a cardan coupling?

What is Cardan shaft coupling?

- Structure of Cardan shaft coupling:

- Function of Cardan shaft coupling:

- Advantages of Cardan shaft coupling:

- Applications of Cardan shaft coupling:

- Maintenance of Cardan shaft coupling:

- Types of Cardan shaft coupling:

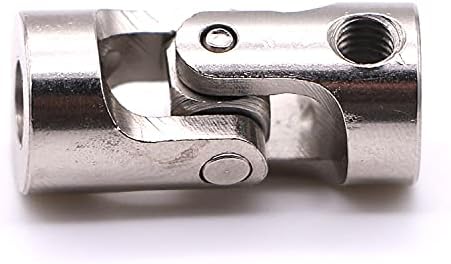

The Cardan shaft coupling consists of two universal joints connected by a shaft. It is designed to transmit torque between two shafts that are not in a straight line.

The main function of the Cardan shaft coupling is to allow for the transmission of power between shafts that are at angles to each other.

Cardan shaft couplings are known for their flexibility, high torque transmission capacity, and ability to compensate for misalignment between shafts.

Cardan shaft couplings are commonly used in automotive, industrial, and agricultural machinery for power transmission.

Regular lubrication and inspection are essential for the proper functioning and longevity of Cardan shaft couplings.

There are various types of Cardan shaft couplings available, including single Cardan shaft, double Cardan shaft, and Cardan shaft with intermediate support.

What is the purpose of a Cardan shaft?

- Transmission of power:

- Compensation for misalignment:

- Reduction of vibration:

- Enhancement of efficiency:

- Flexibility in design:

The primary purpose of a Cardan shaft is to transmit power between two non-aligned shafts.

Cardan shafts can compensate for angular misalignment between the driving and driven shafts.

By absorbing vibration and shock loads, Cardan shafts help to reduce wear and tear on machinery.

Cardan shafts improve the efficiency of power transmission by allowing for smoother operation of machinery.

Cardan shafts offer flexibility in the design of motion control systems, allowing for greater versatility in application.

What is the purpose of a double cardan joint?

- Elimination of velocity fluctuations:

- Reduction of noise and vibration:

- Increased torque transmission:

- Improved driveline angles:

- Enhanced durability:

A double cardan joint helps to eliminate velocity fluctuations in the driveline, resulting in smoother operation.

By providing better alignment between shafts, a double cardan joint helps to reduce noise and vibration in the system.

Double cardan joints are capable of transmitting higher torque compared to single joints, making them suitable for heavy-duty applications.

Double cardan joints allow for greater flexibility in driveline angles, enabling better performance in challenging operating conditions.

By distributing torque evenly and reducing stress on components, double cardan joints contribute to the overall durability of the system.

How to choose the appropriate cardan coupling?

- Consider the application:

- Evaluate shaft sizes:

- Check material compatibility:

- Review maintenance requirements:

- Consider budget and quality:

Understand the specific requirements of the application, including torque, speed, misalignment, and environmental conditions.

Ensure that the Cardan coupling is compatible with the shaft sizes of the equipment to be connected.

Choose materials that are suitable for the operating environment, such as stainless steel for corrosive conditions.

Select a Cardan coupling that aligns with the maintenance schedule and procedures of the machinery.

Weigh the cost of the Cardan coupling against its quality, durability, and performance to make an informed decision.

What is the difference between a disc and a cardan coupling?

- Structural design:

- Flexibility:

- Applications:

- Installation complexity:

- Maintenance requirements:

A disc coupling consists of two discs with a spacer in between, while a Cardan coupling includes universal joints connected by a shaft.

Cardan couplings offer greater angular misalignment capability compared to disc couplings.

Disc couplings are commonly used in high-speed and precision applications, while Cardan couplings are preferred for heavy-duty and industrial applications.

Cardan couplings may require more space and alignment adjustments during installation compared to disc couplings.

Disc couplings are generally maintenance-free, while Cardan couplings may require periodic lubrication and inspection.

About HZPT

Our company, HZPT, established in 2006, is a leading manufacturer and exporter specializing in couplings for motion control systems. With 20 years of ODM and OEM experience, we offer high-quality products, 100% testing before shipment, and 24-hour customer service. Our commitment to customer satisfaction, competitive pricing, and superior product quality has earned us a strong reputation in Europe and the United States. We look forward to providing you with the best solutions for your coupling needs.