Product Description

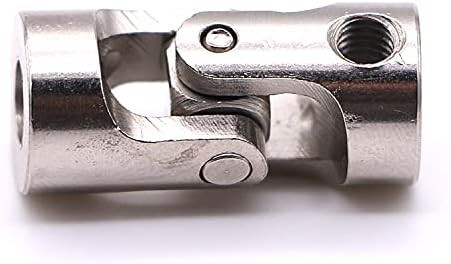

high quality Hardy Spicer Cardan Constant-velocity propshaft steering shaft removing pto coupling double front rear best universal joint

Application of universal joint

Universal joints, also known as U-joints, are mechanical joints that allow 2 shafts to rotate at different angles. They are commonly used in driveshafts to transmit power from the engine to the wheels of a vehicle. U-joints are also used in other applications, such as:

- Wind turbines: U-joints are used in wind turbines to transmit power from the blades to the generator.

- Robotics: U-joints are used in robotics to move the robot’s arms and joints.

- Aircraft: U-joints are used in aircraft to transmit power from the engine to the propeller.

- Machine tools: U-joints are used in machine tools to transmit power from the motor to the cutting tool.

- Conveyors: U-joints are used in conveyors to transmit power from the motor to the conveyor belt.

U-joints are a versatile and reliable component that can be used in a wide variety of applications. They are characterized by their ability to transmit power through a wide range of angles, and their ability to withstand high torque and vibration.

Here are some of the advantages of using universal joints:

- Ability to transmit power through a wide range of angles: U-joints can transmit power through a wide range of angles, which makes them ideal for applications where the shafts are not aligned.

- Ability to withstand high torque and vibration: U-joints are designed to withstand high torque and vibration, which makes them ideal for applications where these forces are present.

- Versatility: U-joints can be used in a wide variety of applications, which makes them a versatile component.

- Reliability: U-joints are designed to be reliable and to last for a long time.

Overall, universal joints are a versatile and reliable component that can be used in a wide variety of applications. They are characterized by their ability to transmit power through a wide range of angles, their ability to withstand high torque and vibration, their versatility, and their reliability.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Handling High Torque and Axial Displacement with Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are designed to transmit torque between two shafts that are not in a straight line. They are versatile components commonly used in various applications, including those requiring high torque and axial displacement.

Handling High Torque: Cardan couplings are capable of handling high levels of torque transmission due to their robust design and construction. The design allows for torque to be transmitted through a series of interconnected components, including the cross-shaped yokes and the bearing assemblies. The use of high-strength materials and precision manufacturing techniques contributes to the coupling’s ability to transmit torque efficiently.

Handling Axial Displacement: While cardan couplings are primarily designed for accommodating angular misalignment, they can also handle a certain degree of axial displacement. Axial displacement refers to the movement of the connected shafts along their axis. However, the axial displacement capacity of a cardan coupling is limited compared to its ability to handle angular misalignment.

It’s important to note that excessive torque or axial displacement beyond the coupling’s design limits can lead to premature wear, increased vibrations, and reduced performance. Manufacturers provide specifications and guidelines for the maximum torque and axial displacement that a specific cardan coupling can handle. Engineers and designers should adhere to these specifications to ensure optimal performance and longevity of the coupling in their applications.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2024-04-03