Product Description

Telescopic Short Cardan Shaft Coupling(SWP-B)

SWP-B split bearing support cardan shaft is short type with length compensation.

SWP partition profile bearing the cross shaft universal coupling products: replacement of bearings for, SWP type cardan design bearing split shaft bolt, suitable for hoisting and conveying machinery and other heavy machinery, connecting 2 different axis transmission shaft, axis angle of A~F type not more than 10 degrees, the G type is not greater than 5 degrees.

|

Model |

D mm |

Tn KN·m |

Tf KN·m |

β |

S mm |

mm |

||||||||

|

D1 |

D2 |

D3 |

E |

E1 |

b×h |

h1 |

L1 |

n-d |

||||||

|

SWP160B |

160 |

16 |

8 |

≤10 |

50 |

140 |

95 |

114 |

15 |

4 |

20×12 |

6 |

85 |

6-13 |

|

SWP180B |

180 |

20 |

10 |

≤10 |

60 |

155 |

105 |

121 |

15 |

4 |

24×14 |

7 |

95 |

6-15 |

|

SWP200B |

200 |

31.5 |

16 |

≤10 |

70 |

175 |

125 |

127 |

17 |

5 |

28×16 |

8 |

110 |

8-15 |

|

SWP225B |

225 |

40 |

20 |

≤10 |

76 |

196 |

135 |

152 |

20 |

5 |

32×18 |

9 |

130 |

8-17 |

|

SWP250B |

250 |

63 |

31.5 |

≤10 |

80 |

218 |

150 |

168 |

25 |

5 |

40×25 |

12.5 |

135 |

8-19 |

|

SWP285B |

285 |

90 |

45 |

≤10 |

100 |

245 |

170 |

194 |

27 |

7 |

40×30 |

15 |

150 |

8-12 |

|

SWP315B |

315 |

140 |

63 |

≤10 |

110 |

280 |

185 |

219 |

32 |

7 |

40×30 |

15 |

170 |

10-23 |

|

SWP350B |

350 |

180 |

90 |

≤10 |

120 |

310 |

210 |

245 |

35 |

8 |

50×32 |

16 |

185 |

10-23 |

|

SWP390B |

390 |

250 |

112 |

≤10 |

120 |

345 |

235 |

273 |

40 |

8 |

70×36 |

18 |

205 |

10-25 |

|

SWP435B |

435 |

355 |

160 |

≤10 |

150 |

385 |

255 |

299 |

42 |

10 |

80×40 |

20 |

235 |

16-28 |

|

SWP480B |

480 |

450 |

224 |

≤10 |

170 |

425 |

275 |

351 |

47 |

12 |

90×45 |

22.5 |

265 |

16-31 |

|

SWP550B |

550 |

710 |

315 |

≤10 |

190 |

492 |

320 |

402 |

50 |

12 |

100×45 |

22.5 |

290 |

16-31 |

|

SWP660B |

600 |

1000 |

500 |

≤10 |

210 |

544 |

380 |

450 |

55 |

15 |

90×55 |

27.5 |

360 |

22-34 |

|

SWP640B |

640 |

1250 |

630 |

≤10 |

230 |

575 |

385 |

480 |

60 |

15 |

100×60 |

30 |

385 |

18-38 |

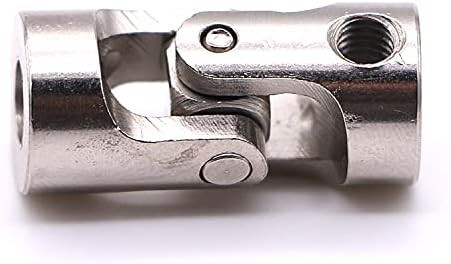

Product picture

Packaging & Shipping

Company Profile

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and TS16949.

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all customers with customized PDF or AI format artwork.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have an excellent price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Suitability of Cardan Couplings for High-Speed and Heavy-Duty Applications

Cardan couplings are well-suited for a wide range of applications, including high-speed and heavy-duty ones. Here’s why:

- High Torque Capacity: Cardan couplings can handle substantial torque loads, making them suitable for heavy-duty machinery and equipment.

- Angular Misalignment: They can accommodate significant angular misalignment, which is common in applications with varying shaft angles.

- Smooth Transmission: Cardan couplings provide smooth and continuous power transmission, essential for precision and stability in high-speed applications.

- Robust Construction: They are often built with durable materials and designed to withstand the stresses of heavy loads and high speeds.

- Shock Absorption: The flexibility of cardan couplings allows them to absorb shocks and vibrations, minimizing the impact on machinery components.

- Versatility: Cardan couplings can connect shafts of different sizes and types, allowing for versatility in various applications.

- Reliable Performance: When properly maintained and installed, cardan couplings offer reliable and consistent performance even in demanding conditions.

However, while cardan couplings are suitable for many high-speed and heavy-duty applications, it’s essential to consider factors such as alignment, lubrication, and maintenance to ensure optimal performance and longevity.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

How do you properly install and maintain a cardan coupling in machinery?

Proper installation and maintenance of a cardan coupling are crucial to ensure its reliable performance and longevity:

- Installation:

- Align the shafts properly before connecting the coupling to minimize initial misalignment.

- Ensure that the universal joints are in phase, meaning their yokes are in the same orientation to prevent uneven torque transmission.

- Follow the manufacturer’s instructions for torque specifications while tightening bolts and fasteners to prevent overloading or loosening during operation.

- Make sure the coupling is properly centered and balanced to avoid vibrations.

- Check for any obstructions or interference that might affect the movement of the coupling.

- Maintenance:

- Regularly inspect the coupling for signs of wear, such as cracks, corrosion, or damaged components.

- Monitor the alignment of the shafts to detect any misalignment that might occur over time.

- Lubricate the universal joints and bearings as recommended by the manufacturer to reduce friction and wear.

- Replace worn or damaged components promptly to prevent further deterioration and potential coupling failure.

- Perform vibration analysis and balancing to ensure the coupling operates smoothly and doesn’t contribute to excessive vibrations in the machinery.

- Regularly check for any signs of overheating, which might indicate inadequate lubrication or other issues.

- Keep the coupling area clean from debris, dirt, and contaminants that could affect its performance.

By following proper installation procedures and conducting regular maintenance checks, you can maximize the efficiency and reliability of a cardan coupling in machinery.

editor by CX 2024-04-26

China Standard Swp-B Cardan Shaft Coupling for Light Industry Machinery

Product Description

Telescopic Short Cardan Shaft Coupling(SWP-B)

SWP-B split bearing support cardan shaft is short type with length compensation.

SWP partition profile bearing the cross shaft universal coupling products: replacement of bearings for, SWP type cardan design bearing split shaft bolt, suitable for hoisting and conveying machinery and other heavy machinery, connecting 2 different axis transmission shaft, axis angle of A~F type not more than 10 degrees, the G type is not greater than 5 degrees.

|

Model |

D mm |

Tn KN·m |

Tf KN·m |

β |

S mm |

mm |

||||||||

|

D1 |

D2 |

D3 |

E |

E1 |

b×h |

h1 |

L1 |

n-d |

||||||

|

SWP160B |

160 |

16 |

8 |

≤10 |

50 |

140 |

95 |

114 |

15 |

4 |

20×12 |

6 |

85 |

6-13 |

|

SWP180B |

180 |

20 |

10 |

≤10 |

60 |

155 |

105 |

121 |

15 |

4 |

24×14 |

7 |

95 |

6-15 |

|

SWP200B |

200 |

31.5 |

16 |

≤10 |

70 |

175 |

125 |

127 |

17 |

5 |

28×16 |

8 |

110 |

8-15 |

|

SWP225B |

225 |

40 |

20 |

≤10 |

76 |

196 |

135 |

152 |

20 |

5 |

32×18 |

9 |

130 |

8-17 |

|

SWP250B |

250 |

63 |

31.5 |

≤10 |

80 |

218 |

150 |

168 |

25 |

5 |

40×25 |

12.5 |

135 |

8-19 |

|

SWP285B |

285 |

90 |

45 |

≤10 |

100 |

245 |

170 |

194 |

27 |

7 |

40×30 |

15 |

150 |

8-12 |

|

SWP315B |

315 |

140 |

63 |

≤10 |

110 |

280 |

185 |

219 |

32 |

7 |

40×30 |

15 |

170 |

10-23 |

|

SWP350B |

350 |

180 |

90 |

≤10 |

120 |

310 |

210 |

245 |

35 |

8 |

50×32 |

16 |

185 |

10-23 |

|

SWP390B |

390 |

250 |

112 |

≤10 |

120 |

345 |

235 |

273 |

40 |

8 |

70×36 |

18 |

205 |

10-25 |

|

SWP435B |

435 |

355 |

160 |

≤10 |

150 |

385 |

255 |

299 |

42 |

10 |

80×40 |

20 |

235 |

16-28 |

|

SWP480B |

480 |

450 |

224 |

≤10 |

170 |

425 |

275 |

351 |

47 |

12 |

90×45 |

22.5 |

265 |

16-31 |

|

SWP550B |

550 |

710 |

315 |

≤10 |

190 |

492 |

320 |

402 |

50 |

12 |

100×45 |

22.5 |

290 |

16-31 |

|

SWP660B |

600 |

1000 |

500 |

≤10 |

210 |

544 |

380 |

450 |

55 |

15 |

90×55 |

27.5 |

360 |

22-34 |

|

SWP640B |

640 |

1250 |

630 |

≤10 |

230 |

575 |

385 |

480 |

60 |

15 |

100×60 |

30 |

385 |

18-38 |

Product picture

Packaging & Shipping

Company Profile

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and TS16949.

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all customers with customized PDF or AI format artwork.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have an excellent price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Recent Technological Advancements in Cardan Coupling Design

In recent years, there have been notable advancements and innovations in the design of cardan couplings:

- Material Enhancements: Advances in materials science have led to the development of high-strength and lightweight materials that can improve the performance and durability of cardan couplings.

- Sealing Technology: Improved sealing mechanisms and materials help prevent contamination and enhance the lifespan of cardan couplings.

- Computer-Aided Design (CAD): CAD software allows for more precise and optimized design of cardan couplings, leading to better performance and reduced stress concentrations.

- Finite Element Analysis (FEA): FEA techniques enable engineers to simulate the behavior of cardan couplings under various loads and conditions, aiding in design optimization.

- Lubrication Systems: Innovations in lubrication systems ensure efficient and consistent lubrication, reducing wear and enhancing coupling longevity.

- Monitoring and Diagnostics: Integration of sensors and monitoring systems enables real-time data collection for performance analysis, predictive maintenance, and early detection of issues.

- Customization: Advanced manufacturing techniques allow for more customization, making it possible to design cardan couplings tailored to specific applications.

These advancements contribute to the overall efficiency, reliability, and performance of cardan couplings, making them more suitable for a wide range of applications.

Comparison of Cardan Couplings with Other Flexible Couplings

Cardan couplings, universal joints, and gear couplings are all types of flexible couplings used to transmit torque while accommodating misalignment. Here’s how a cardan coupling compares to other flexible coupling types:

1. Cardan Couplings:

– Also known as shaft couplings or u-joints.

– Typically consist of two yokes connected by a cross-shaped component called a spider.

– Accommodate angular misalignment.

– Limited to relatively lower speeds and torques.

– Provide moderate torsional flexibility.

2. Universal Joints:

– Consist of two yokes connected by cross-shaped pins and bearings.

– Accommodate angular misalignment similar to cardan couplings.

– Can transmit higher torques than cardan couplings.

– Limited in their ability to handle axial and parallel misalignment.

– Used in various applications, including automotive and industrial equipment.

3. Gear Couplings:

– Feature toothed gears that mesh to transmit torque.

– Accommodate angular, axial, and parallel misalignment.

– Suitable for high-speed and high-torque applications.

– Provide high torsional rigidity and accurate torque transmission.

– Require proper lubrication and maintenance.

When comparing these coupling types:

– Cardan couplings are simple and cost-effective solutions for moderate torque and speed applications with angular misalignment.

– Universal joints are versatile but may have limitations in handling higher torques and other misalignment types.

– Gear couplings offer superior torque and misalignment handling but are more complex and may require more maintenance.

The choice of coupling type depends on the specific application’s torque, speed, misalignment, and precision requirements.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2024-02-26

China Good quality SWC-BH Universal Joint Coupling Shaft Cardan Shaft Coupling for Transportation Machinery

Product Description

SWC-BH Universal Joint Coupling Shaft Cardan Shaft Coupling for Transportation Machinery

Description:

The SWC universal joint coupling is a structure without bolts. The bearing is fixed without bolts. It avoids the weak links damaged by bolt shearing, prolongs the service life and is convenient for maintenance. It is suitable for rolling machinery, lifting and transportation machinery and other heavy machinery. It connects 2 transmission shafts with different axes, the rotation diameter is 100 to 620mm, the nominal torque is 1.25 to 1000kN m, and the axis angle is 15 to 25 degrees.

Advantages:

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Packing & shipping

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Suitability of Cardan Couplings for High-Speed and Heavy-Duty Applications

Cardan couplings are well-suited for a wide range of applications, including high-speed and heavy-duty ones. Here’s why:

- High Torque Capacity: Cardan couplings can handle substantial torque loads, making them suitable for heavy-duty machinery and equipment.

- Angular Misalignment: They can accommodate significant angular misalignment, which is common in applications with varying shaft angles.

- Smooth Transmission: Cardan couplings provide smooth and continuous power transmission, essential for precision and stability in high-speed applications.

- Robust Construction: They are often built with durable materials and designed to withstand the stresses of heavy loads and high speeds.

- Shock Absorption: The flexibility of cardan couplings allows them to absorb shocks and vibrations, minimizing the impact on machinery components.

- Versatility: Cardan couplings can connect shafts of different sizes and types, allowing for versatility in various applications.

- Reliable Performance: When properly maintained and installed, cardan couplings offer reliable and consistent performance even in demanding conditions.

However, while cardan couplings are suitable for many high-speed and heavy-duty applications, it’s essential to consider factors such as alignment, lubrication, and maintenance to ensure optimal performance and longevity.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

What is a cardan coupling and how is it used in mechanical systems?

A cardan coupling, also known as a universal joint or U-joint coupling, is a mechanical component used to transmit torque between two shafts that are not in alignment but intersect at an angle. It consists of a cross-shaped yoke with two perpendicular shafts connected at its ends, allowing the transmission of rotational motion even when the shafts are at different angles to each other. Cardan couplings are widely used in mechanical systems to transmit torque and motion where angular misalignment is present.

Here’s how a cardan coupling works and how it is used in mechanical systems:

- Angular Misalignment: Cardan couplings are designed to accommodate angular misalignment between shafts. They can transmit torque between shafts that are at an angle to each other, typically up to 45 degrees. This ability to handle misalignment makes them suitable for various applications.

- Components: A cardan coupling consists of a cross-shaped yoke with four arms, two of which are connected to the input and output shafts. The two remaining arms are connected to each other through a bearing, which allows for the rotational motion.

- Transmitting Torque: As one shaft rotates, it imparts angular motion to the yoke. This angular motion is transferred to the other shaft through the bearing, allowing torque to be transmitted even when the shafts are not collinear.

- Application: Cardan couplings are used in various applications, including automotive drivetrains, industrial machinery, agricultural equipment, and even in some aerospace systems. They are often found in places where it’s necessary to transmit torque between non-parallel shafts while allowing for some degree of flexibility.

- Advantages: Cardan couplings are simple in design, relatively compact, and provide a cost-effective solution for transmitting torque in cases of angular misalignment. They are also capable of transmitting high torques while compensating for misalignment.

- Limitations: Cardan couplings have limitations in terms of the angle they can handle, and at extreme angles, they may produce uneven torque output due to their design. They can also introduce some degree of vibration and require periodic maintenance.

In mechanical systems, cardan couplings are used in various applications where the alignment between shafts cannot be maintained, such as in vehicles with independent suspension systems, industrial machinery with non-parallel shafts, and applications where flexibility and torque transmission are required despite angular misalignment.

editor by CX 2024-01-12

China Standard Cardan Joint Drive Shaft Coupling Used for Pipe Mill Machinery SWC390e

Product Description

Cardan joint drive shaft coupling used for pipe mill machinery SWC390E

Brief Introduction

Processing flow

Why choose us!

Quality Control

Product Description

| Structure | Type E | Flexible or Rigid | Rigid | Standard or Nonstandard | Standard |

| Material | Alloy steel | Brand name | HangZhou XIHU (WEST LAKE) DIS. | Place of origin | HangZhou |

| Model | SWC390E-2100 | Raw materials | Casting and forging | Length | 2100mm |

| Flange DIA | 390mm | Nominal torque | 320KN.m | Coating | Heavy duty industrial paint |

| Paint clour | Customization | Application | Tube Mill | OEM/ODM | Available |

| Certification | ISO,TUV,SGS | Price | calculate according to model | Custom service | Available |

Packaging & Delivery

Packaging details:Standard plywood case

Delivery detail: 15 -20 working days,depend on the actual produce condition

FAQ

Q: Are you trading company or manufacturer ?

A: We are a professional manufacturer specializing in manufacturing cardan shafts. We supply cardan shafts for the wholesalers , dealers and end-users from different countries.

Q: Can you do OEM? And what is your min order ?

A: Yes, absolutely. Generally, min order is1 set. Most of our products are Customized. Each order from our factory, we always produce cardan shaft after customer confirmed the drawing. So we didn’t have stock.

Q: How does your factory do regarding quality control?

A:Quality is priority! We always attach great importance to quality controlling from the very beginning to the end:

1) Firstly, we have QC department to control the quality

2) Secondly, we have all detailed records for nonconformity products, then we will make summary according to these records, avoid it happen again.

3) Thirdly,All complaints from customers about quality are reported directly to the general manager.

4)Fourthly,Have first-class production equipment, including CNC Machines and machining center.

Recent Technological Advancements in Cardan Coupling Design

In recent years, there have been notable advancements and innovations in the design of cardan couplings:

- Material Enhancements: Advances in materials science have led to the development of high-strength and lightweight materials that can improve the performance and durability of cardan couplings.

- Sealing Technology: Improved sealing mechanisms and materials help prevent contamination and enhance the lifespan of cardan couplings.

- Computer-Aided Design (CAD): CAD software allows for more precise and optimized design of cardan couplings, leading to better performance and reduced stress concentrations.

- Finite Element Analysis (FEA): FEA techniques enable engineers to simulate the behavior of cardan couplings under various loads and conditions, aiding in design optimization.

- Lubrication Systems: Innovations in lubrication systems ensure efficient and consistent lubrication, reducing wear and enhancing coupling longevity.

- Monitoring and Diagnostics: Integration of sensors and monitoring systems enables real-time data collection for performance analysis, predictive maintenance, and early detection of issues.

- Customization: Advanced manufacturing techniques allow for more customization, making it possible to design cardan couplings tailored to specific applications.

These advancements contribute to the overall efficiency, reliability, and performance of cardan couplings, making them more suitable for a wide range of applications.

Common Industries and Applications of Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used in various industries and applications that require torque transmission and flexibility in shaft connections. Some common examples include:

- Automotive Industry: Cardan couplings are used in driveshafts to transmit power from the engine to the wheels while allowing for variable angles and misalignment caused by suspension movement.

- Industrial Machinery: They are used in heavy machinery such as mining equipment, cranes, and manufacturing machinery to transmit torque between non-aligned shafts.

- Agricultural Machinery: Tractors and other agricultural equipment utilize cardan couplings in drivelines to accommodate varying angles and lengths.

- Marine Applications: Cardan couplings are used in marine propulsion systems to transmit torque between the engine and the propeller shaft, even when the shafts are at different angles.

- Aerospace Industry: They are employed in aerospace applications such as aircraft control systems and helicopter rotor drives to accommodate movements and misalignments.

- Railway Systems: Cardan couplings are used in railway drivelines to transmit torque between cars and locomotives while allowing for movement and misalignment.

- Energy Sector: They find applications in power generation systems, including wind turbines, where they accommodate misalignments caused by dynamic loads.

- Pumps and Compressors: Cardan couplings are used in pumps and compressors to transmit power while compensating for misalignment and vibration.

These examples demonstrate the versatility of cardan couplings in various industries where torque transmission, flexibility, and angular misalignment compensation are essential.

Are there different types of cardan couplings for various applications?

Yes, there are different types of cardan couplings designed to suit various applications and requirements:

- Single Universal Joint: This is the most common type of cardan coupling, consisting of two yokes connected by a cross-shaped center piece. It is suitable for applications where angular misalignment compensation is needed, but the shafts are not too far apart.

- Double Cardan Joint: Also known as a double U-joint or CV joint, this type consists of two universal joints connected by an intermediate shaft. It is used when higher angles of misalignment need to be accommodated or when a constant velocity transmission is required.

- Disc Type Coupling: This type uses flexible discs or plates to transmit torque and compensate for misalignment. It is often used in applications with limited space and moderate torque requirements.

- Block Type Coupling: Block type cardan couplings use solid blocks or spheres to transmit torque. They are suitable for heavy-duty applications and can handle higher torque loads.

- Floating Shaft Coupling: This design involves two shafts connected by a third floating shaft, which allows for even higher angles of misalignment and smoother torque transmission.

- Needle Bearing Universal Joint: In this type, needle bearings are used to reduce friction and improve efficiency. It is often used in precision applications where low friction and high efficiency are crucial.

The choice of cardan coupling type depends on factors such as the amount of misalignment, torque requirements, available space, and the need for constant velocity transmission. Selecting the right type ensures optimal performance and longevity in various mechanical systems.

editor by CX 2023-08-18

China best quality low sales price for china manufacturer agriculture machinery parts Picker poly doffer White Urethane for JD cotton picker machine,AN272152 Factory Manufacturer and Supplier -from Pto-shaft.com

“EPG” model rotocultivator ploughshares in T.S. whole strains created in our manufacturing unit have been analyzed and appraised by the Ministry of Agriculture and have acquired the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic of China.

Overview

Quick Details

- Guarantee:

-

1.five a long time

- Applicable Industries:

-

farms

- Soon after Guarantee Service:

-

Online video technical assistance

- Neighborhood Support Place:

-

canada. turkey. None

- Showroom Area:

-

Egypt

- Online video outgoing-inspection:

-

Offered

- EPT Te EPT Report:

-

Presented

- Advertising and marketing Type:

-

EPT Item 2020

- Guarantee of core elements:

-

1.5 years

- Main Elements:

-

Gearbox. Gear

- Key Marketing Details:

-

lengthy support lifestyle

- Product Name:

-

Doffer

- Software:

-

agricultural harvester Machine

- MOQ:

-

10 Pcs

- Shipping and delivery time:

-

15DAYS

- Material:

-

polyurethane

- Color:

-

white

- Model:

-

mianyou

- certifications:

-

ISO9001

EPT Capability

- EPT Capacity:

- 200000 Piece/Pieces per Month

Packaging & Shipping

- Packaging Information

- Large Density Picker Spindle Assembly Fits John Deere.Correct Hand is packaged in box.

- Port

- Shanghai/Ninbo

-

Guide Time

: -

Amount(Luggage) 1 – 2000 >2000 Est. Time(days) fifteen To be negotiated

Online Customization

Merchandise Description

| Item Title | cotton picker doffer |

| Materials | polyurethane |

| Software | Agricultural Mahinery |

| Certification | ISO9001 |

| Shade | White |

| JD CODE | AN272152 |

| MOQ | ten Pcs |

| Delivery time | Inside of fifteen Times |

| Deal | Common Bundle |

Product Screen

Relater Products

Organization Info

Logistics Supply

1.Q:Are you company or trade organization?Exactly where?

A:We are company which positioned in HangZhou.ZheJiang China . EPG – a single of the bigge EPT Agri- EPT parts manufacturing unit in China .

2.Q:What is your terms of payment ?

A: Payment=10000USD. fifty% T/T in ept .harmony just before cargo. Irrepealable LC at sight for massive buy is substantial.

three.Q:What about supply time?

A:The shipping and delivery time relies upon on item and quantity .If you want to know the actual time. E mail us the amount.we will check out the time for you.

four.Q:Is the site price the final value?

A:No. All the costs are negotiable depending on the amounts.

five.Q:How will you handle item top quality?

A:We strickly control each element of creation and each merchandise is inspected by our QC team just before shipping. In addition.our production is abided by ISO 9001.

six.Q:When can you get the reply?

A:Any inquiries will be replied inside 24 hrs.Our sales staff will try out our be EPT to assistance you.

EPG – As one particular of the most significant equipment transmission and agricultural part and equipment manufacturing unit in China, we will supply your substantial good quality products with cheapest price tag. We update new items monthly from pto-shaft.com

factory Lowest price manufacturer for agricultural industry machinery parts forged stainless steel pinion bevel spur gear wheel

We are aiming to meet the requires of the consumers about the planet.. a specialised supplier of a entire selection of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Neighborhood Support Location:

-

None

- Surface area remedy:

-

Blacking, Sprucing, Anodization, Chrome Plating, Zinc Plating

- Certification:

-

ISO/TS16949:2009

- Standard:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Module:

-

M1-M8

- Regular or Nonstandard:

-

Nonstandard

- Tolerance:

-

Outer Diameter Based on drawingLength Dimension

- Warmth treatment:

-

Quenching & Tempering, Carburizing & Quenching

- Pressure Angle:

-

20/40/50/sixty Personalized

Supply Potential

- Source Ability:

- 5000 Piece/Parts for every Thirty day period

Packaging & Delivery

- Packaging Information

- Neutral paper packaging, picket containers for outer box or in accordance to customer’s demand.

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Parts) 1 – one thousand >1000 Est. Time(times) fifteen To be negotiated

On the internet Customization

We At any time-Electricity Team with 4 branches in excess of 1200 staff is a single of the most significant transmission elements and machining items makers in China

Product Description

agricultural sector machinery components forged stainless steel pinion bevel spur gear wheel

(1). All types of gears, shaft, gear shaft, precision gear and CNC gear.

(two). Specialized in producing all varieties of auto transmission part based mostly on drawings

(3). Material: ductile forged iron, carbon metal, alloy steel , stainless metal, , bronze/brass

(4). Modules: M1 to M8

(5). Fulfills ISO, DIN and ASTM standards

(six). Specification : In accordance to the the drawing

|

Material |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Metal |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-one, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Manage |

Outer Diameter |

Based on drawing |

|

Duration Dimension |

Based on drawing |

|

|

Machining Procedure |

Gear Hobbing, Equipment Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Equipment Lapping |

|

|

Tooth Precision |

DIN Class four, ISO/GB Class four, AGMA Class 13, JIS Course |

|

|

Modules |

1., one.twenty five, one.5, one.75, 2., 2.twenty five, 2.five….eight. and so forth |

|

|

Warmth Treatment |

Quenching & Tempering, Carburizing & Quenching, Substantial-frequency Hardening, Carbonitriding |

|

|

Surface Treatment method |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Regular |

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Packaging & Shipping