Introducing Cardan Coupling for Dairy Equipment

Keyword Content:

- Cardan coupling

- Dairy equipment

- High quality

- Low price

- Customizable

- CE and TUV certificates

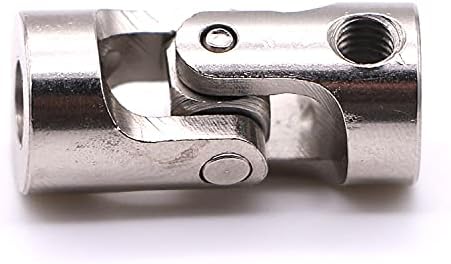

What is Cardan shaft coupling?

Definition:

A Cardan shaft coupling, also known as a universal joint, is a mechanical component that allows for the transmission of torque between two shafts that are not in a straight line.

Function:

It is used to transmit power smoothly even when the shafts are at different angles to each other.

Components:

Consists of a cross-shaped piece with needle bearings and bearing caps that allow for the rotational movement required for the shafts.

Applications:

Commonly used in vehicles, industrial machinery, and agricultural equipment to accommodate misalignment between shafts.

Advantages:

Provides flexibility, smooth power transmission, and durability under various operating conditions.

What is the purpose of a Cardan shaft?

Power Transmission:

Transfers torque from the engine to the wheels in vehicles.

Compensation for Misalignment:

Allows for variations in shaft angles and distances.

Reducing Vibrations:

Absorbs shocks and vibrations during operation.

Enhancing Efficiency:

Ensures consistent power transmission without loss.

Improving Safety:

Prevents damage to connected machinery due to misalignment.

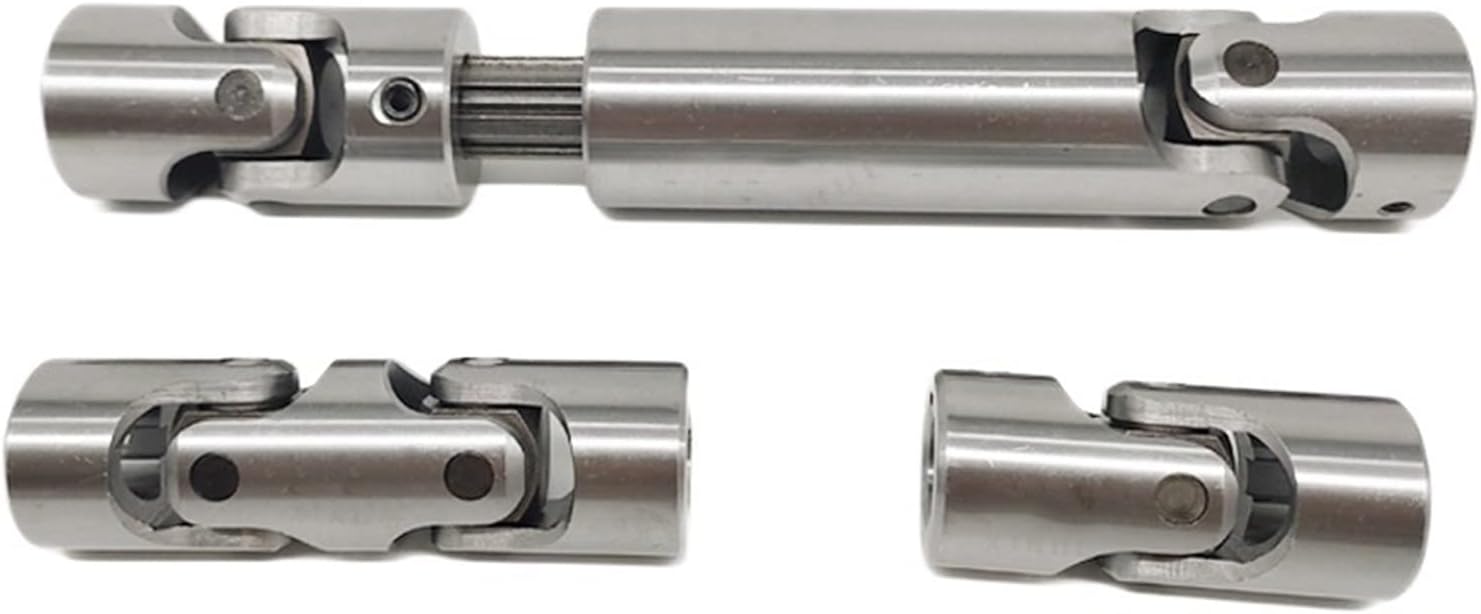

What is the purpose of a double cardan joint?

Increased Flexibility:

Allows for greater angles and misalignments compared to a single universal joint.

Reduced Noise:

Offers smoother operation and reduced vibrations for quieter performance.

Enhanced Durability:

Withstands higher loads and operating conditions due to its design.

Improved Efficiency:

Provides more consistent power transmission with less energy loss.

Suitable for Complex Systems:

Ideal for applications with multiple shaft connections and varying angles.

How to Choose the Appropriate Cardan Coupling

Consider Operating Conditions:

Evaluate factors such as temperature, speed, and torque requirements.

Shaft Misalignment Capability:

Choose a coupling that can accommodate the expected misalignment angles.

Material Selection:

Opt for materials that offer high strength, corrosion resistance, and durability.

Installation and Maintenance:

Select a coupling that is easy to install and maintain for long-term reliability.

Customization Options:

Look for suppliers that offer customization to meet specific application needs.

What is the difference between a disc and a cardan coupling?

Design:

Disc couplings have a compact design with higher torque density, while Cardan couplings allow for more misalignment.

Flexibility:

Disc couplings offer high torsional stiffness, while Cardan couplings provide flexibility in shaft alignment.

Application:

Disc couplings are suitable for high-speed, high-precision machinery, while Cardan couplings are ideal for applications with misalignment.

Cost:

Disc couplings are generally more expensive due to their precision manufacturing, while Cardan couplings are cost-effective for standard applications.

Maintenance:

Disc couplings require regular alignment checks and maintenance, while Cardan couplings are more forgiving of misalignment issues.

About HZPT

Our company, HZPT, established in 2006, specializes in the design, development, and production of couplings for various industries, including dairy equipment. With 16 years of experience, we offer high-quality, customizable products with CE and TUV certificates. Our commitment to customer satisfaction, competitive pricing, and superior service has earned us a strong reputation among customers in Europe and the United States. Choose HZPT for reliable couplings that meet your specific needs.