Introduction to Cardan Coupling for Spinning Machines

Keyword Content:

- Cardan shaft coupling

- What is Cardan shaft coupling?

- What is the purpose of a Cardan shaft?

- What is the purpose of a double cardan joint?

- How to choose the appropriate cardan coupling

- What is the difference between a disc and a cardan coupling?

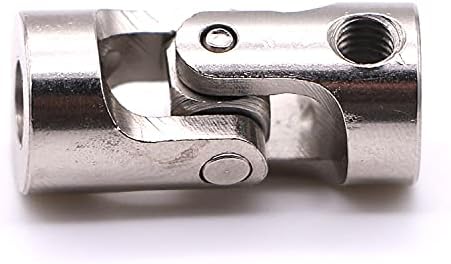

What is Cardan shaft coupling?

Cardan shaft coupling, also known as universal joint coupling, is a mechanical device used to connect two shafts at an angle to transmit torque. It consists of a cross-shaped piece with needle bearings that allow for flexibility and rotation in multiple directions.

Aspects of Cardan Shaft Coupling:

- Flexibility in Transmission

- Angular Misalignment Compensation

- High Torque Transmission

- Smooth Operation

- Applications in Spinning Machines

What is the purpose of a Cardan shaft?

A Cardan shaft, also known as a drive shaft, is used to transmit mechanical power between two shafts that are not in line with each other. It is commonly found in vehicles, industrial equipment, and machinery to transfer torque from the engine to the wheels or other driven components.

Aspects of Cardan Shaft Purpose:

- Power Transmission

- Angular Misalignment Compensation

- Vibration Dampening

- Reduced Maintenance

- Efficient Energy Transfer

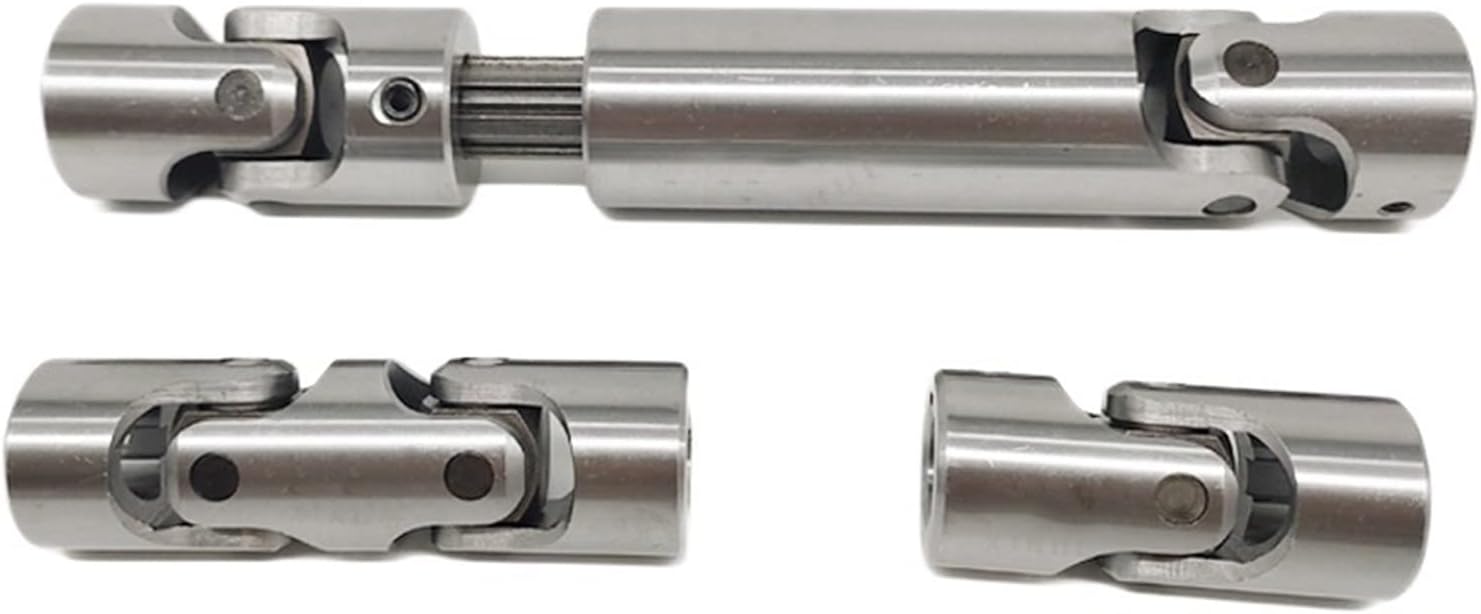

What is the purpose of a double cardan joint?

A double cardan joint, also known as a constant-velocity joint, is designed to provide constant velocity and smooth power transmission in applications where angular misalignment is present. It is commonly used in automotive drive shafts and off-road vehicles to reduce vibration and improve performance.

Aspects of Double Cardan Joint Purpose:

- Constant Velocity Transmission

- Angular Misalignment Compensation

- Reduced Vibration

- Improved Performance

- Enhanced Durability

How to choose the appropriate cardan coupling

Choosing the right cardan coupling for spinning machines is crucial to ensure optimal performance and longevity. Here are key points to consider:

- Operating Speed and Torque Requirements

- Shaft Misalignment Compensation

- Environmental Conditions

- Installation Space Constraints

- Maintenance and Serviceability

What is the difference between a disc and a cardan coupling?

Disc couplings and cardan couplings are both used to transmit torque between shafts, but they have distinct differences in design and performance. Here are the key aspects differentiating the two:

- Flexibility and Misalignment Compensation

- Size and Weight

- Cost and Maintenance

- Load Capacity and Torque Transmission

- Applications and Industries

About HZPT

Our company, HZPT, established in 2006, specializes in designing, developing, and producing various couplings, including Cardan couplings for spinning machines. With 20 years of ODM and OEM experience, we ensure high-quality products at competitive prices. Our commitment to customer satisfaction and product excellence has earned us a strong reputation in Europe and the United States. Contact us for customized orders and experience our top-notch service and quality products.