Introduction to Cardan Coupling for Asphalt Pavers

Keyword Content:

- Cardan shaft coupling

- What is Cardan shaft coupling?

- What is the purpose of a Cardan shaft?

- What is the purpose of a double cardan joint?

- How to choose the appropriate cardan coupling

- What is the difference between a disc and a cardan coupling?

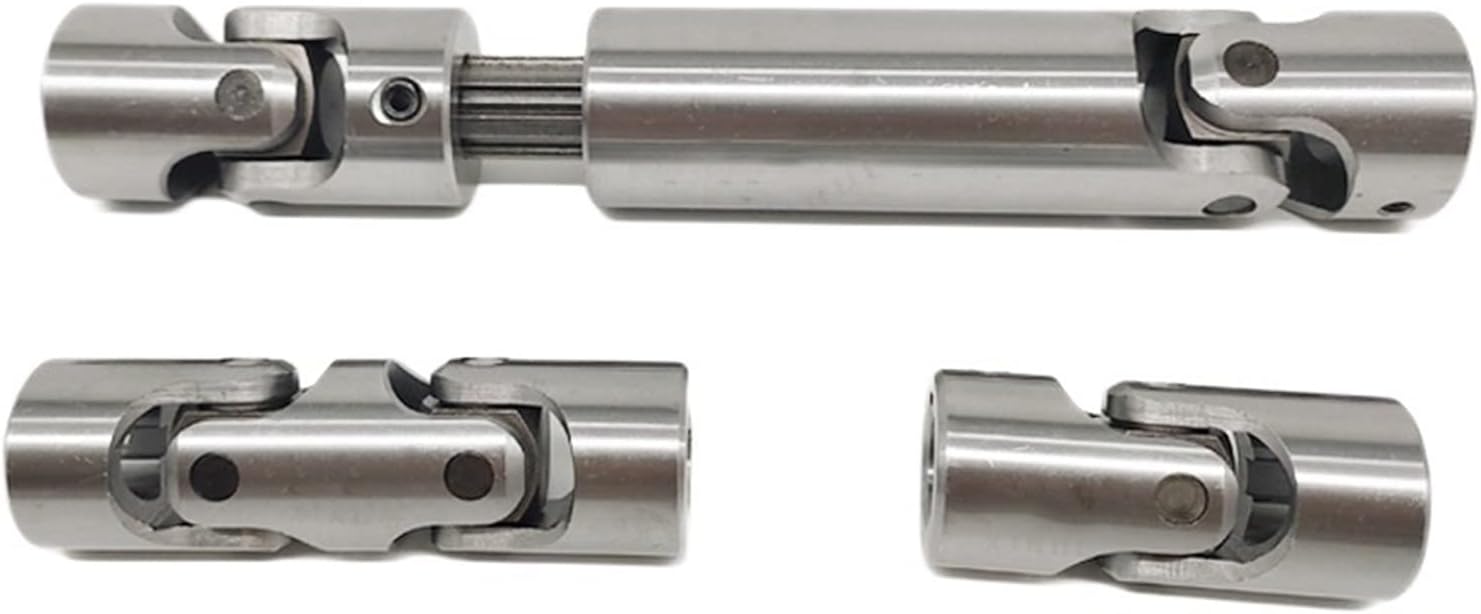

What is Cardan shaft coupling?

A Cardan shaft coupling, also known as a universal joint, is a mechanical device used to transmit torque between two shafts that are not in a straight line. It consists of two yokes connected by a cross-shaped intermediate component, allowing for flexibility and angular misalignment.

Aspects:

- Flexibility in shaft alignment

- Transmitting torque efficiently

- Reducing vibrations and noise

- Long-lasting and durable

- Used in various industrial applications

What is the purpose of a Cardan shaft?

A Cardan shaft, or propeller shaft, is used to transmit power from the engine to the wheels of a vehicle, allowing for torque to be transferred at an angle. It is essential for the smooth operation of the vehicle and ensuring power is distributed effectively.

Aspects:

- Connecting the engine to the wheels

- Transmitting power at an angle

- Allowing for suspension movement

- Compensating for misalignment

- Enhancing vehicle performance

What is the purpose of a double cardan joint?

A double cardan joint, also known as a constant-velocity joint, is used to maintain a constant speed and smooth power transmission in vehicles with non-linear powertrain configurations. It helps to reduce vibrations and improve efficiency.

Aspects:

- Minimizing vibrations

- Ensuring constant speed

- Enhancing power transmission

- Improving efficiency

- Used in front-wheel drive vehicles

How to choose the appropriate cardan coupling

When selecting a cardan coupling for asphalt pavers, there are several key factors to consider:

Key Points:

- Load capacity and torque requirements

- Shaft misalignment and angle compensation

- Environmental conditions and material compatibility

- Installation space and mounting options

- Cost-effectiveness and maintenance considerations

What is the difference between a disc and a cardan coupling?

The differences between a disc and a cardan coupling lie in their design, functionality, and application:

Aspects:

- Design structure and flexibility

- Transmitting torque and angular misalignment

- Performance in high-speed applications

- Installation and maintenance requirements

- Cost and efficiency in specific industrial uses

About HZPT

Our company, HZPT, specializes in the design, development, and production of high-quality couplings for various industrial applications. With over 16 years of experience, we offer customized solutions to meet the unique requirements of our global customers. Our products are CE and TUV certified, ensuring reliability and performance.

At HZPT, we prioritize customer satisfaction and provide 24-hour service to address any inquiries or concerns. Our commitment to quality, innovation, and competitive pricing has earned us a strong reputation among customers in Europe and the United States. Choose HZPT for superior coupling solutions and exceptional service.