Introducing Cardan Coupling for Cardboard Box Manufacturing Equipment

Keyword Content:

- Cardan coupling

- Cardboard box manufacturing

- Equipment

What is Cardan shaft coupling?

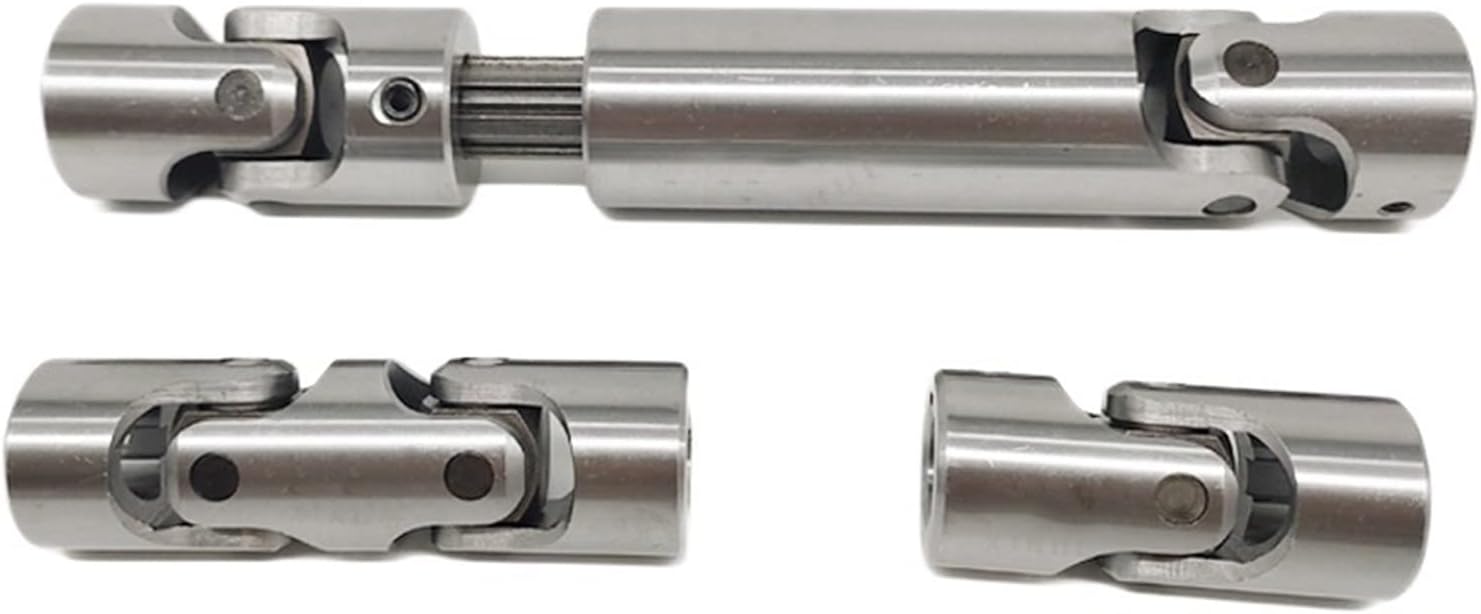

A Cardan shaft coupling, also known as a universal joint, is a mechanical device used to connect shafts at an angle in order to transmit torque. It consists of two forked yokes connected by a cross-shaped intermediate component called the spider.

What is the purpose of a Cardan shaft?

A Cardan shaft is designed to transmit torque between shafts that are not in a straight line. It allows for flexibility and can accommodate misalignment between the shafts.

What is the purpose of a double cardan joint?

A double Cardan joint, also known as a CV joint, is used to reduce vibration and allow for smoother power transmission in applications where significant misalignment occurs.

How to choose the appropriate cardan coupling?

1. Consider the torque requirements of your application and choose a coupling that can handle the necessary load.

2. Take into account the speed at which the equipment will operate and choose a coupling with an appropriate maximum speed rating.

3. Evaluate the misalignment present in your system and select a coupling that can accommodate the required angular and axial misalignment.

4. Consider the environmental conditions in which the coupling will operate and choose a material that can withstand harsh environments.

5. Ensure compatibility with existing equipment by selecting a coupling with the appropriate shaft sizes and connection methods.

What is the difference between a disc and a cardan coupling?

1. Design: A disc coupling uses flexible discs to transmit torque, while a Cardan coupling uses universal joints.

2. Misalignment Capacity: Disc couplings can accommodate higher levels of misalignment compared to Cardan couplings.

3. Maintenance: Disc couplings require less maintenance due to their simple design, while Cardan couplings may require more frequent inspection and lubrication.

4. Cost: Cardan couplings are generally more cost-effective than disc couplings.

5. Application: Disc couplings are often used in high-speed and high-torque applications, while Cardan couplings are suitable for applications with moderate misalignment requirements.

About HZPT

Our company, HZPT, established in 2006, specializes in the design, development, and production of couplings. With 16 years of experience, we offer customized products and have a comprehensive quality inspection system. Our commitment to customer satisfaction drives us to provide the best service and highest product quality. Choose HZPT for reliable couplings at competitive prices.