Introducing Cardan Coupling for Forestry Equipment

When it comes to forestry equipment, a reliable and durable Cardan coupling is essential for smooth operation. Let’s delve into the details of what makes Cardan couplings ideal for forestry equipment:

1. High Strength and Durability

Cardan couplings are known for their high strength and durability, making them perfect for the rugged conditions encountered in forestry operations. They can withstand heavy loads and constant movement without compromising performance.

2. Flexibility and Precision

These couplings offer flexibility and precision in transmitting power between shafts at different angles. This flexibility is crucial in forestry equipment where various components need to work together seamlessly.

3. Smooth and Efficient Power Transmission

Cardan couplings ensure smooth and efficient power transmission, reducing energy loss and maximizing the performance of forestry equipment. This leads to increased productivity and cost-effectiveness.

4. Easy Maintenance and Installation

With their simple design and easy installation process, Cardan couplings require minimal maintenance, saving time and effort for forestry equipment operators. This ensures minimal downtime and maximum productivity.

5. Versatility and Adaptability

Cardan couplings are versatile and adaptable to different forestry equipment applications, making them a versatile choice for various machinery requirements. They can be customized to fit specific needs and ensure optimal performance.

6. Cost-Effective Solution

Overall, Cardan couplings offer a cost-effective solution for forestry equipment, providing long-lasting performance and reliability without breaking the budget. Their efficiency and durability make them a wise investment for any forestry operation.

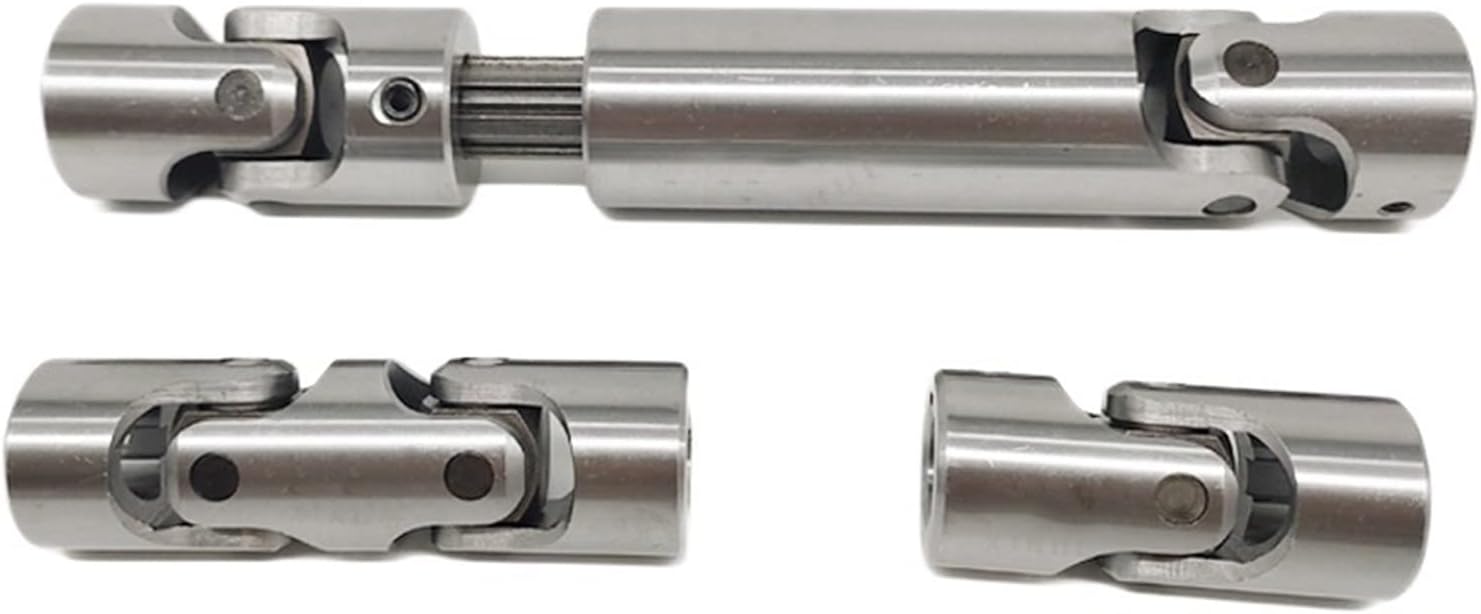

What is Cardan Shaft Coupling?

Cardan shaft coupling, also known as universal joint coupling, is a mechanical device used to transmit torque and rotation between shafts that are not in a straight line. It consists of two yokes connected by a cross-shaped intermediate member called the spider. The versatility and efficiency of Cardan shaft couplings make them ideal for various industries and applications.

1. Flexibility and Angular Misalignment

Cardan shaft couplings can accommodate angular misalignment between shafts, allowing for smooth power transmission even when the shafts are not perfectly aligned. This flexibility reduces stress on machinery components and ensures efficient operation.

2. Torque Transmission

These couplings are designed to transmit torque from one shaft to another, ensuring the smooth and efficient transfer of power. This is crucial in applications where precise torque transmission is required for optimal performance.

3. Vibration Dampening

Cardan shaft couplings can help dampen vibrations generated during operation, reducing noise and minimizing wear on machinery components. This results in smoother operation and extended equipment lifespan.

4. Maintenance and Longevity

With proper maintenance, Cardan shaft couplings can last a long time, providing reliable performance and durability. Regular inspection and lubrication can help prevent wear and tear, ensuring the longevity of the coupling and the machinery it serves.

5. Wide Range of Applications

Cardan shaft couplings are versatile and can be used in various industries, including automotive, aerospace, and manufacturing. Their ability to transmit power efficiently and accommodate misalignment makes them a popular choice for diverse applications.

What is the Purpose of a Cardan Shaft?

Cardan shafts, also known as propeller shafts or drive shafts, serve a crucial role in transmitting power from the engine to the wheels or other components in vehicles and machinery. Let’s explore the key purposes of a Cardan shaft:

1. Power Transmission

One of the primary purposes of a Cardan shaft is to transmit power from the engine to the wheels or other driven components in vehicles and machinery. This ensures that the vehicle or equipment can move and operate effectively.

2. Flexibility and Misalignment Compensation

Cardan shafts can accommodate angular misalignment between the engine and the driven components, allowing for smooth power transmission even when the shafts are not perfectly aligned. This flexibility reduces stress on the drivetrain and improves overall performance.

3. Vibration Reduction

By dampening vibrations generated during operation, Cardan shafts help reduce noise and minimize wear on vehicle components. This results in a smoother and more comfortable driving or operating experience for the user.

4. Torque Transmission

Cardan shafts are designed to transmit torque from the engine to the wheels or other driven components, ensuring that the vehicle or machinery can move efficiently and effectively. This torque transmission is essential for optimal performance.

5. Maintenance and Longevity

With proper maintenance and care, Cardan shafts can last a long time and provide reliable performance. Regular inspection, lubrication, and replacement of worn components can help extend the lifespan of the shaft and the equipment it serves.

What is the Purpose of a Double Cardan Joint?

A double Cardan joint, also known as a constant velocity joint, serves a specific purpose in providing a smooth and constant power transfer between two shafts at an angle. Let’s explore the key purposes of a double Cardan joint:

1. Constant Velocity

The primary purpose of a double Cardan joint is to maintain a constant velocity between two shafts that are not in a straight line. This ensures smooth and efficient power transfer without fluctuations in speed or performance.

2. Angular Misalignment Compensation

Double Cardan joints can accommodate angular misalignment between shafts, allowing for flexible power transmission even when the shafts are not perfectly aligned. This flexibility reduces stress on machinery components and improves overall performance.

3. Vibration Reduction

By dampening vibrations generated during operation, double Cardan joints help reduce noise and minimize wear on machinery components. This results in smoother operation and extended equipment lifespan.

4. Torque Transmission

Double Cardan joints are designed to transmit torque between shafts, ensuring the smooth and efficient transfer of power. This is essential for applications where precise torque transmission is required for optimal performance.

5. Maintenance and Longevity

With proper maintenance and care, double Cardan joints can provide reliable performance and durability. Regular inspection and lubrication can help prevent wear and tear, ensuring the longevity of the joint and the machinery it serves.

How to Choose the Appropriate Cardan Coupling

Choosing the right Cardan coupling for your specific application is crucial for optimal performance and efficiency. Here are key points to consider when selecting the appropriate Cardan coupling:

1. Load Capacity

Consider the maximum load capacity that the Cardan coupling needs to handle in your application. Choose a coupling that can withstand the required load without compromising performance or safety.

2. Speed and Torque Requirements

Determine the speed and torque requirements of your application to select a Cardan coupling that can transmit power efficiently at the desired levels. Ensure that the coupling can handle the necessary speed and torque without overheating or failing.

3. Misalignment Tolerance

Assess the degree of misalignment between shafts in your application and choose a Cardan coupling that can accommodate this misalignment without causing excessive stress or wear on machinery components. Opt for a coupling with high misalignment tolerance for smooth operation.

4. Maintenance and Serviceability

Consider the maintenance requirements of the Cardan coupling and choose a design that is easy to inspect, lubricate, and service. Select a coupling that allows for quick and convenient maintenance to minimize downtime and maximize productivity.

5. Application Specific Features

Look for Cardan couplings with features that are tailored to your specific application requirements, such as corrosion resistance, vibration damping, or special material compatibility. Choose a coupling that meets all the unique needs of your application for optimal performance.

What is the Difference Between a Disc and a Cardan Coupling?

Disc couplings and Cardan couplings are two common types of couplings used in various industries for power transmission. Let’s explore the key differences between these two couplings:

1. Flexibility and Misalignment Compensation

One of the main differences between disc and Cardan couplings is their ability to accommodate angular misalignment between shafts. Cardan couplings can handle higher degrees of misalignment compared to disc couplings, making them more versatile in challenging applications.

2. Torque Transmission Efficiency

While both disc and Cardan couplings are designed to transmit torque between shafts, Cardan couplings offer higher torque transmission efficiency due to their design and construction. This makes them ideal for applications with high torque requirements.

3. Vibration Dampening Capability

Cardan couplings excel in dampening vibrations generated during operation, reducing noise and minimizing wear on machinery components. Disc couplings may provide some level of vibration dampening but are not as effective as Cardan couplings in this regard.

4. Installation and Maintenance

Disc couplings are typically easier to install and maintain compared to Cardan couplings, as they have a simpler design and fewer moving parts. This can lead to lower maintenance costs and reduced downtime for machinery equipped with disc couplings.

5. Application Suitability

Choose between disc and Cardan couplings based on the specific requirements of your application. Disc couplings are suitable for applications with moderate torque and misalignment, while Cardan couplings are preferred for high torque, high misalignment, and vibration-sensitive applications.

About HZPT

As a leading manufacturer and exporter of couplings, HZPT has been providing high-quality products and exceptional service to customers worldwide since 2006. Our commitment to customer satisfaction and product excellence has earned us a strong reputation in the European and American markets.

At HZPT, we prioritize quality, reliability, and innovation in every product we offer. With our experienced design and R&D team, we can customize couplings to meet the unique requirements of our global customers. All our products undergo rigorous quality inspection and hold CE and TUV certifications for added assurance.

When you choose HZPT, you can expect 20 years of ODM and OEM experience, 100% testing before shipment, 24/7 customer service, and competitive pricing. Our dedication to excellence and customer satisfaction sets us apart in the industry, making us the preferred choice for high-quality couplings.