Introducing Cardan Coupling for Stone Cutting Machines

Keyword Content:

- What is Cardan shaft coupling?

- What is the purpose of a Cardan shaft?

- What is the purpose of a double cardan joint?

- How to choose the appropriate cardan coupling?

- What is the difference between a disc and a cardan coupling?

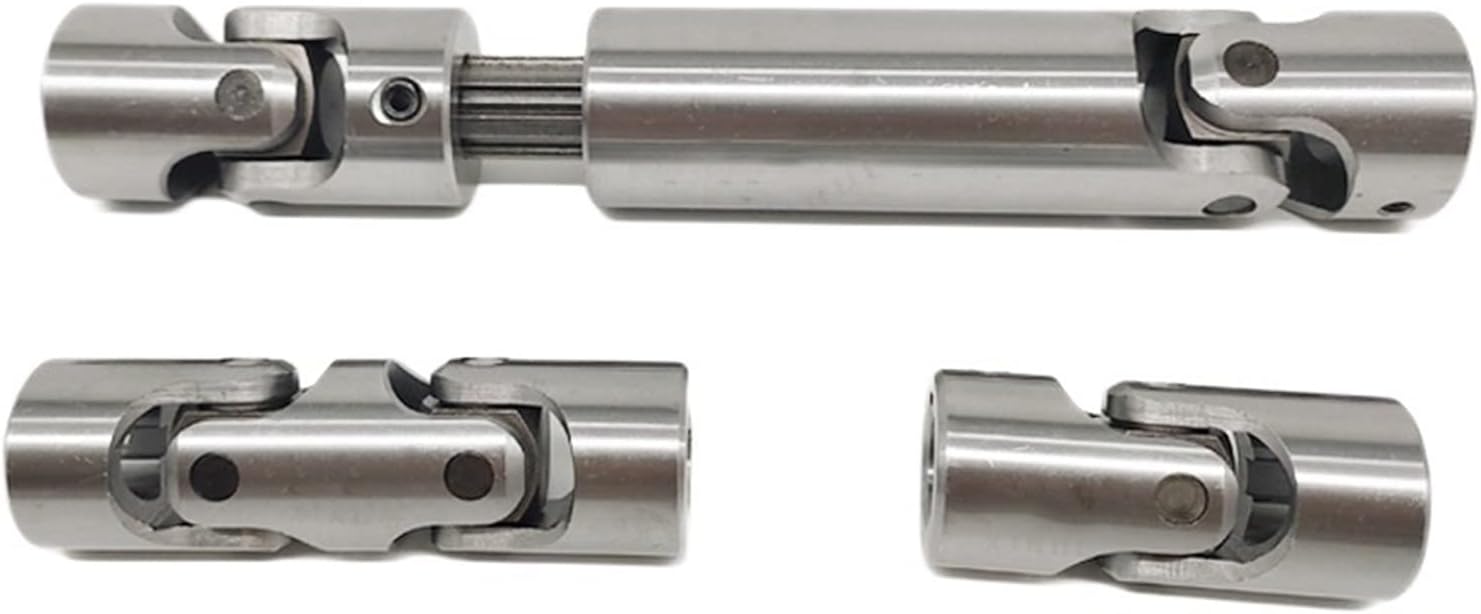

What is Cardan Shaft Coupling?

- Cardan shaft coupling, also known as universal joint coupling, is a mechanical device used to connect shafts at angles that are not in line with each other.

- It consists of a cross-shaped joint with four arms connected by bearings that allow for smooth rotation and transmission of power.

- Cardan shaft couplings are commonly used in stone cutting machines to transfer power efficiently and effectively.

- These couplings are designed to withstand high torque and provide flexibility in various working conditions.

- They are essential components in stone cutting machines to ensure precise cutting and smooth operation.

What is the Purpose of a Cardan Shaft?

- A Cardan shaft, also known as a drive shaft, is used to transmit power from the engine to the wheels or cutting blades of the stone cutting machine.

- It allows for the transfer of power at different angles and distances, providing flexibility in the machine’s operation.

- The Cardan shaft helps maintain a consistent speed and torque output, ensuring efficient cutting performance.

- It also helps in reducing vibrations and noise during operation, resulting in smoother cutting and increased precision.

- Overall, the Cardan shaft plays a crucial role in the proper functioning of stone cutting machines.

What is the Purpose of a Double Cardan Joint?

- A double cardan joint, also known as a constant velocity joint, is used to provide continuous power transmission at varying angles.

- It helps in maintaining a constant velocity during operation, reducing vibrations and ensuring smooth cutting performance.

- The double cardan joint is ideal for stone cutting machines that require precise and consistent power delivery for accurate cutting results.

- It helps in minimizing wear and tear on the machine components, prolonging the machine’s lifespan.

- Overall, the double cardan joint enhances the efficiency and reliability of stone cutting machines.

How to Choose the Appropriate Cardan Coupling?

- Consider the power and torque requirements of the stone cutting machine to select a cardan coupling that can handle the workload effectively.

- Choose a cardan coupling with high-quality materials and robust construction to ensure durability and long-lasting performance.

- Ensure that the cardan coupling is compatible with the machine’s specifications and requirements for seamless integration.

- Opt for a cardan coupling with proper lubrication and maintenance features to prolong its lifespan and reduce the risk of breakdowns.

- Consult with experts or manufacturers to get customized recommendations for the most suitable cardan coupling for your stone cutting machine.

What is the Difference Between a Disc and a Cardan Coupling?

- Disc couplings are rigid and provide high torque transmission, while cardan couplings offer flexibility and smooth power transfer.

- Disc couplings are more compact and lightweight compared to cardan couplings, making them suitable for limited space applications.

- Cardan couplings can accommodate misalignments and angular variations better than disc couplings, ensuring smooth operation in stone cutting machines.

- Disc couplings are ideal for high-speed applications, while cardan couplings are preferred for applications that require flexibility and damping of vibrations.

- Overall, the choice between a disc and a cardan coupling depends on the specific requirements and operating conditions of the stone cutting machine.

About HZPT

Our company, HZPT, established in 2006, specializes in the design, development, and production of couplings, including cardan couplings for stone cutting machines. With 16 years of experience, we offer customized products, quality inspection, and excellent customer service. Our products have CE and TUV certificates, ensuring high quality and reliability. We take pride in our reputation in Europe and the United States, providing competitive prices and the best service to our valued customers. Choose HZPT for top-notch couplings and a trusted partner for your machinery needs.