Introducing Cardan Shaft Coupling

Keyword Content:

- Definition of Cardan Shaft Coupling

- Components of Cardan Shaft Coupling

- Benefits of Using Cardan Shaft Coupling

- Applications of Cardan Shaft Coupling

- Types of Cardan Shaft Coupling

- Features of Cardan Shaft Coupling

What is Cardan Shaft Coupling?

Definition:

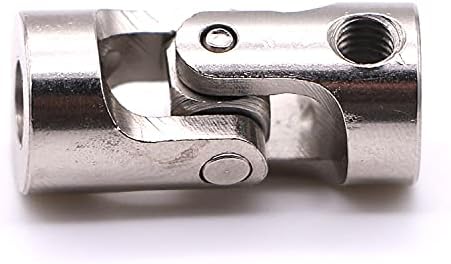

A Cardan shaft coupling, also known as a universal joint, is a mechanical component used to connect two shafts at an angle in order to transmit torque between them.

Components:

The main components of a Cardan shaft coupling include two yokes, a center block, and two bearing caps.

Benefits:

Cardan shaft couplings allow for the transmission of power between shafts that are not in a straight line, providing flexibility and reducing vibration.

Applications:

These couplings are commonly used in vehicles, industrial machinery, and agricultural equipment to transfer power efficiently.

Types:

There are various types of Cardan shaft couplings, including single joint, double joint, and telescopic joint, each suited for different applications.

Features:

Cardan shaft couplings are known for their durability, high torque capacity, and low maintenance requirements, making them a popular choice in various industries.

What is the Purpose of a Cardan Shaft?

1. Transmitting Power:

A cardan shaft is used to transmit power from the engine to the wheels or other components of a vehicle or machinery.

2. Flexibility:

It allows for flexibility in the drivetrain, accommodating misalignment and reducing stress on components.

3. Absorbing Vibration:

Cardan shafts help in absorbing and dampening vibrations generated during operation, leading to smoother performance.

4. Connection of Non-Parallel Shafts:

They enable the connection of shafts that are not in a straight line, providing a versatile solution for power transmission.

5. Maintenance of Constant Velocity:

Cardan shafts help in maintaining constant velocity even when the shafts are at an angle, ensuring efficient power transfer.

What is the Purpose of a Double Cardan Joint?

1. Improved Articulation:

A double cardan joint allows for improved articulation in the drivetrain, making it ideal for off-road vehicles and heavy-duty machinery.

2. Minimizing Vibrations:

It helps in minimizing vibrations and noise, providing a smoother and quieter operation.

3. Increased Torque Capacity:

Double cardan joints can handle higher torque loads compared to single joints, making them suitable for demanding applications.

4. Reducing Wear and Tear:

By distributing the torque more evenly, double cardan joints help in reducing wear and tear on the drivetrain components.

5. Enhancing Durability:

These joints are known for their durability and reliability, ensuring long-lasting performance in challenging conditions.

How to Choose the Appropriate Cardan Coupling

1. Consider the Application:

Identify the specific application requirements, such as torque capacity, speed, and alignment, to choose the right type of cardan coupling.

2. Evaluate Operating Conditions:

Take into account factors like temperature, environment, and maintenance needs to select a coupling that can withstand the operating conditions.

3. Determine Shaft Misalignment:

Understand the degree of misalignment between the shafts to choose a cardan coupling that can accommodate it without causing stress on the system.

4. Check Compatibility:

Ensure that the coupling is compatible with the shaft sizes, mounting requirements, and other components in the system for seamless integration.

5. Consider Maintenance Needs:

Choose a cardan coupling that is easy to maintain and service, minimizing downtime and ensuring continuous operation.

What is the Difference Between a Disc and a Cardan Coupling?

1. Design:

A disc coupling consists of thin metal discs, while a cardan coupling uses universal joints to connect shafts at an angle.

2. Flexibility:

Disc couplings offer less flexibility in terms of misalignment compared to cardan couplings, which can accommodate greater angles.

3. Torque Capacity:

Cardan couplings generally have higher torque capacity than disc couplings, making them suitable for heavy-duty applications.

4. Maintenance:

Disc couplings require more frequent maintenance due to wear on the discs, while cardan couplings are known for their durability and low maintenance needs.

5. Applications:

Disc couplings are often used in high-speed and precision applications, while cardan couplings are preferred for applications requiring flexibility and torque transmission.

About HZPT

HZPT is a leading manufacturer and exporter specializing in the design and production of high-quality couplings. Established in 2006, we have 16 years of experience in the industry and a dedicated team for product development. Our products are widely used in various machinery industries both domestically and internationally.

We prioritize customer satisfaction and offer customized solutions to meet specific requirements. With CE and TUV certifications, our products are guaranteed to meet the highest quality standards. Our competitive prices, 24/7 customer service, and commitment to innovation make us the preferred choice for customers in Europe and the United States.

Choose HZPT for reliable, durable, and efficient couplings that meet your needs and exceed your expectations.