Introduction to Coupling Cardan

When it comes to connecting shafts and transmitting power, the coupling cardan plays a crucial role. Here are six key points to understand about this essential component:

- Flexible Power Transmission: The coupling cardan allows for the transfer of power between shafts that are not aligned perfectly.

- Angular Misalignment: It can accommodate angular misalignment between the input and output shafts.

- Smooth Operation: By reducing vibration and shock, the coupling cardan ensures a smoother operation of machinery.

- High Torque Capacity: It has the ability to transmit high levels of torque, making it suitable for heavy-duty applications.

- Longevity: With proper maintenance, the coupling cardan can have a long service life, contributing to the overall efficiency of the machinery.

- Versatility: It can be used in various industrial sectors, including automotive, aerospace, and manufacturing.

What is Cardan Shaft Coupling?

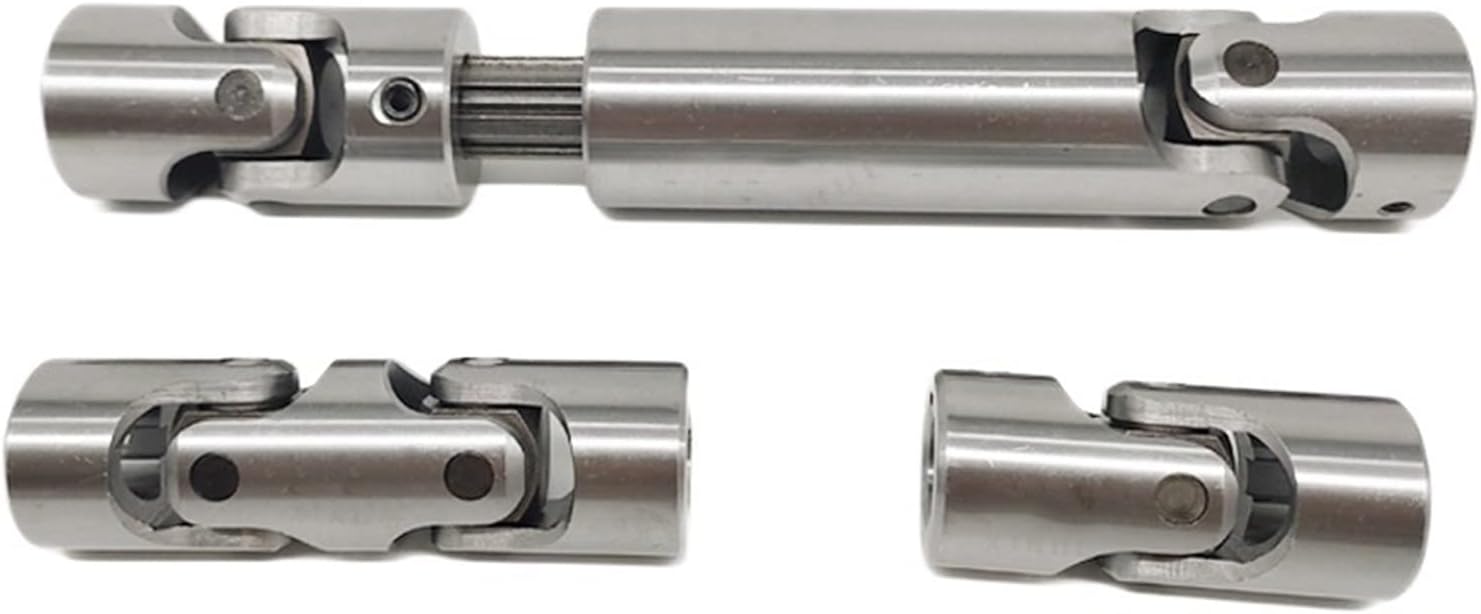

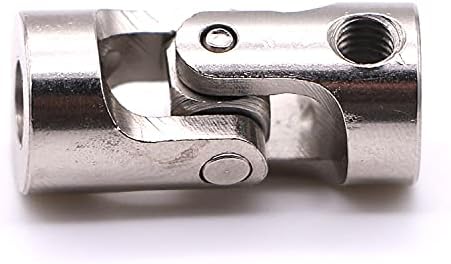

1. Structural Composition:

The cardan shaft coupling consists of two yokes connected by a cross-shaped intermediate member, allowing for the transmission of power at various angles.

2. Functionality:

It is designed to transfer torque between shafts that are not perfectly aligned, accommodating misalignment and reducing stress on the machinery.

3. Applications:

Commonly used in vehicles, industrial machinery, and agricultural equipment, the cardan shaft coupling provides reliable power transmission.

4. Benefits:

Offers flexibility, high torque capacity, and durability, contributing to the efficient operation of the machinery.

5. Maintenance:

Regular maintenance and lubrication are essential to ensure the longevity and performance of the cardan shaft coupling.

What is the Purpose of a Cardan Shaft?

1. Power Transmission:

The primary purpose of a cardan shaft is to transmit power between the input and output shafts, allowing for the efficient operation of machinery.

2. Misalignment Compensation:

It compensates for angular misalignment between shafts, reducing wear and tear on the components.

3. Vibration Reduction:

By absorbing vibration and shock, the cardan shaft contributes to a smoother and quieter operation of the machinery.

4. Versatility:

It can be used in various applications, including vehicles, industrial equipment, and agricultural machinery, due to its adaptability to different angles.

5. Durability:

The cardan shaft is designed to withstand high levels of torque and stress, ensuring a long service life with proper maintenance.

What is the Purpose of a Double Cardan Joint?

Double cardan joints are designed to provide additional flexibility and stability in power transmission applications. Here are five key aspects of their purpose:

1. Enhanced Angular Misalignment:

Double cardan joints can accommodate higher levels of angular misalignment compared to single cardan joints, making them suitable for more demanding applications.

2. Improved Vibration Dampening:

By incorporating two universal joints, double cardan joints offer better vibration dampening properties, contributing to smoother operation.

3. Increased Torque Capacity:

With the ability to transmit higher levels of torque, double cardan joints are ideal for heavy-duty machinery that requires robust power transmission.

4. Reducing Driveline Angles:

Double cardan joints help to minimize the operating angles of the driveline, reducing wear and tear on the components and extending the service life of the equipment.

5. Versatility:

They can be used in a wide range of applications, including off-road vehicles, industrial machinery, and construction equipment, due to their versatility and durability.

How to Choose the Appropriate Cardan Coupling

Choosing the right cardan coupling is essential for the efficient operation of machinery. Here are five key points to consider:

1. Application Requirements:

Understand the specific power transmission needs of your machinery, including torque capacity, misalignment compensation, and operating conditions.

2. Shaft Sizes:

Ensure that the cardan coupling is compatible with the shaft sizes of the input and output components, as well as the overall design of the machinery.

3. Material Selection:

Choose a cardan coupling made from high-quality materials that can withstand the operating conditions and provide long-term durability.

4. Maintenance Needs:

Consider the maintenance requirements of the cardan coupling, including lubrication intervals, inspection schedules, and replacement parts availability.

5. Budget Constraints:

Balance the cost of the cardan coupling with the quality and performance requirements of your machinery, ensuring a cost-effective solution that meets your needs.

What is the Difference Between a Disc and a Cardan Coupling?

1. Structural Design:

A disc coupling consists of two metal discs connected by a spacer, while a cardan coupling has two yokes connected by a cross-shaped intermediate member.

2. Flexibility:

Disc couplings offer higher torsional stiffness and accuracy, while cardan couplings provide more flexibility in accommodating misalignment.

3. Torque Transmission:

Disc couplings are suitable for high-speed and high-torque applications, while cardan couplings are better for moderate torque levels with angular misalignment.

4. Maintenance Requirements:

Disc couplings often require precision alignment during installation and periodic maintenance, while cardan couplings are more forgiving of misalignment and easier to maintain.

5. Application Suitability:

Disc couplings are commonly used in pumps, compressors, and turbines, while cardan couplings are preferred in automotive, industrial, and agricultural machinery due to their flexibility.

About HZPT

Our company, HZPT, established in 2006, is a leading manufacturer and exporter specializing in the design, development, and production of couplings. With 16 years of experience, we have a dedicated design and R&D team that can tailor products to meet the needs of global customers. We have a rigorous quality inspection system in place, ensuring that all our products meet the highest standards and are backed by CE and TUV certificates.

At HZPT, customer satisfaction is our top priority. We offer 24-hour service, ODM and OEM packaging options, and competitive pricing to meet the needs of our customers in Europe and the United States. Our product range includes radial elastic couplings, tire couplings, drum gear couplings, and more, designed to provide reliable and efficient power transmission solutions for various industries.

Choose HZPT for the best quality, service, and value in couplings. We look forward to building successful partnerships with new customers worldwide.