Introduction to Cardan Coupling for Pulp Mills

Keyword Content:

1. Cardan coupling

2. Pulp mills

3. Shaft coupling

4. Coupling for industrial use

5. Flexible coupling

6. High torque transmission

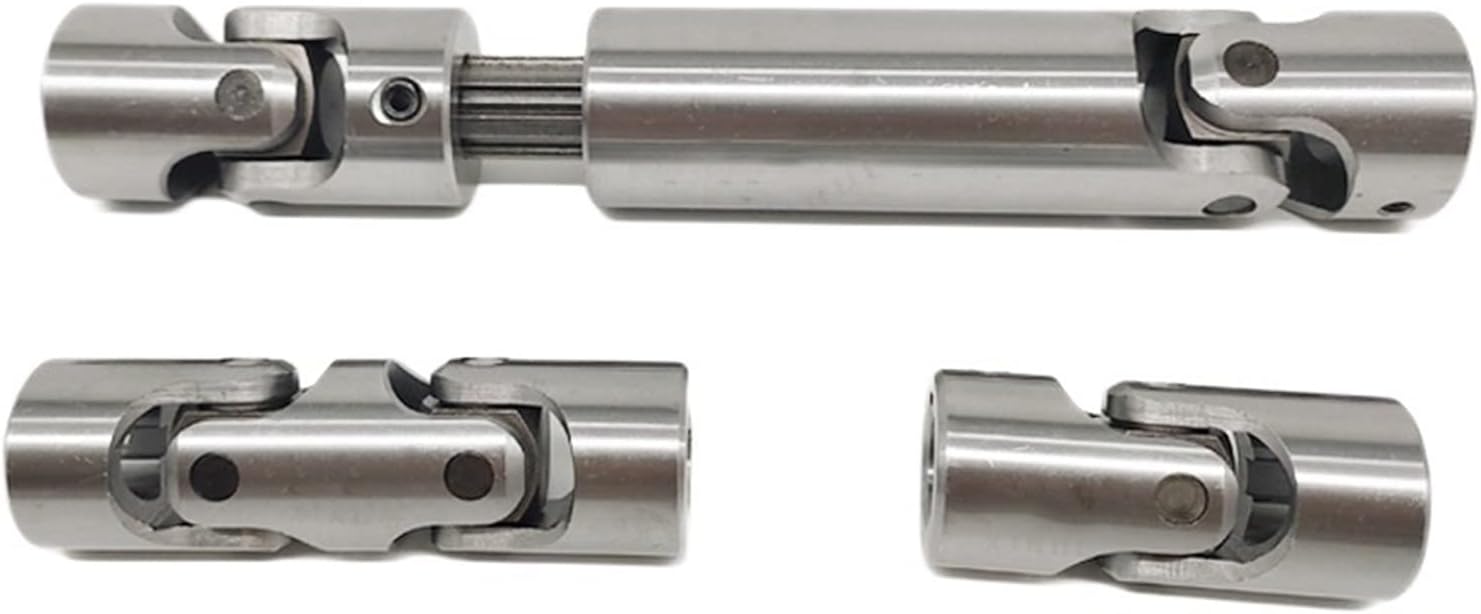

What is Cardan shaft coupling?

A Cardan shaft coupling, also known as a universal joint coupling, is a mechanical device used to connect two shafts at an angle in order to transmit torque. It provides flexibility in terms of misalignment and compensates for axial, radial, and angular shaft movements. Cardan shaft couplings are commonly used in various industrial applications due to their versatility and efficiency.

What is the purpose of a Cardan shaft?

The purpose of a Cardan shaft is to transmit torque from one shaft to another at a variable angle. It allows for the transfer of power between two shafts that are not in alignment, thereby enabling the smooth operation of machinery and equipment. Cardan shafts are essential components in the drive systems of vehicles, industrial machinery, and other mechanical systems.

What is the purpose of a double cardan joint?

A double cardan joint, also known as a constant-velocity joint, is used to provide constant rotational speed and torque transmission even at varying angles. It consists of two Cardan joints assembled together with a centering yoke to eliminate velocity fluctuations and reduce vibration in the drivetrain. Double cardan joints are commonly employed in vehicles, especially in the propeller shafts of four-wheel-drive systems.

How to choose the appropriate Cardan coupling?

1. Consider the torque requirements of the application and select a Cardan coupling with the appropriate torque rating.

2. Evaluate the operating conditions such as speed, misalignment, and environmental factors to determine the type of coupling needed.

3. Choose a coupling material that can withstand the specific demands of the application, such as corrosion resistance or high temperature tolerance.

4. Select a coupling design that allows for easy installation and maintenance to ensure long-term reliability.

5. Consult with a coupling specialist or manufacturer to get expert advice on the best coupling solution for your specific requirements.

What is the difference between a disc and a Cardan coupling?

1. Design: A disc coupling uses disc-shaped elements to transmit torque, while a Cardan coupling utilizes universal joints for torque transmission.

2. Flexibility: Cardan couplings offer greater angular misalignment capacity compared to disc couplings.

3. Maintenance: Disc couplings require periodic inspection and replacement of disc elements, whereas Cardan couplings have fewer components and may require less maintenance.

4. Cost: Cardan couplings are generally more cost-effective than disc couplings due to their simpler design and construction.

5. Application: Disc couplings are commonly used in high-speed, high-torque applications, while Cardan couplings are suitable for a wide range of industrial applications requiring flexibility and torque transmission.

About HZPT

Basic information

Our company, HZPT, established in 2006, is a leading manufacturer and exporter specializing in the design, development, and production of couplings. With a dedicated design and R&D team for over 16 years, we offer customized solutions to meet the diverse needs of our global customers. Our comprehensive quality inspection system ensures that all our products meet high standards and are certified with CE and TUV certificates.

Advantages

1. 20 years of ODM and OEM experience

2. 100% testing before shipment

3. 24-hour service support

4. Use of premium materials for product durability

5. Competitive factory direct sales pricing

6. Customized packaging and branding options available

Our philosophy

We believe in surviving through quality and developing through reputation. Our commitment to providing high-quality products at competitive prices has earned us a solid reputation among customers in Europe and the United States. We strive for customer satisfaction and aim to build successful business relationships with clients worldwide.