Introduction to Cardan Coupling for Sawmills

When it comes to optimizing the performance of sawmills, a key component that plays a crucial role is the Cardan coupling. This specialized coupling is designed to provide smooth and efficient power transmission in sawmill machinery. Let’s explore the features and benefits of Cardan coupling for sawmills:

What is Cardan Shaft Coupling?

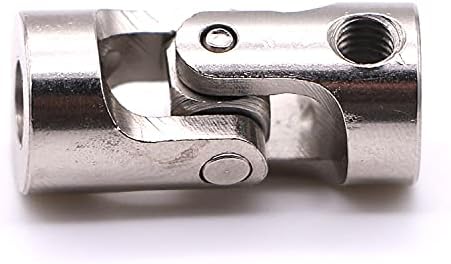

A Cardan shaft coupling, also known as a universal joint coupling, is a mechanical device used to transmit torque between two shafts that are not in a straight line. It consists of a cross-shaped component with needle bearings that allow for rotational movement in multiple directions. The primary function of a Cardan shaft coupling is to compensate for misalignment and provide smooth power transmission.

What is the Purpose of a Cardan Shaft?

1. Flexibility: A Cardan shaft allows for flexibility in transmitting torque between non-aligned shafts, making it ideal for sawmill machinery that requires smooth and efficient power transmission.

2. Misalignment Compensation: The Cardan shaft coupling can compensate for angular and parallel misalignments between shafts, ensuring optimal performance and reducing wear and tear on the machinery.

3. Vibration Damping: By absorbing shocks and vibrations during operation, the Cardan shaft helps to reduce noise and improve overall stability in sawmill machinery.

4. Torque Transmission: The Cardan shaft coupling efficiently transmits torque between shafts, ensuring consistent power delivery and enhancing the productivity of sawmill operations.

5. Maintenance: With its durable construction and reliable performance, the Cardan shaft requires minimal maintenance, resulting in cost savings and increased operational efficiency for sawmills.

What is the Purpose of a Double Cardan Joint?

1. Increased Angular Range: The double Cardan joint allows for a greater angular range of movement compared to a single Cardan joint, making it suitable for applications that require enhanced flexibility.

2. Reduced Noise and Vibration: By incorporating two Cardan joints, the double Cardan joint can effectively dampen vibrations and reduce noise levels during operation, contributing to a quieter and more stable working environment in sawmills.

3. Improved Durability: The double Cardan joint’s design distributes torque evenly across both joints, resulting in reduced wear and tear on the components and extending the lifespan of the coupling in high-demand sawmill applications.

4. Enhanced Power Transmission: With its dual joint configuration, the double Cardan joint ensures consistent and efficient power transmission between shafts, enabling sawmills to achieve optimal performance and productivity.

5. Versatile Applications: The double Cardan joint is versatile and can be used in various sawmill machinery configurations to accommodate different operational requirements, providing flexibility and adaptability in demanding working conditions.

How to Choose the Appropriate Cardan Coupling

1. Shaft Size and Speed: Consider the shaft size and operating speed of your sawmill machinery to ensure that the Cardan coupling can handle the required torque and rotational speed.

2. Misalignment Tolerance: Evaluate the degree of misalignment between shafts in your sawmill equipment and choose a Cardan coupling with the appropriate angular compensation capabilities to maintain smooth power transmission.

3. Load Capacity: Determine the maximum load capacity that the Cardan coupling needs to support in your sawmill operations to prevent overload and ensure reliable performance under heavy-duty conditions.

4. Environmental Conditions: Take into account the operating environment of your sawmill, including temperature, humidity, and exposure to contaminants, and select a Cardan coupling that is resistant to corrosion and wear for long-lasting durability.

5. Maintenance Requirements: Choose a Cardan coupling that is easy to maintain and service to minimize downtime and reduce operational costs in your sawmill facility.

What is the Difference Between a Disc and a Cardan Coupling?

1. Flexibility: The Cardan coupling offers greater flexibility in compensating for misalignment between shafts compared to a disc coupling, making it suitable for applications with varying alignment requirements.

2. Torque Transmission: While both couplings are designed to transmit torque between shafts, the Cardan coupling provides smoother and more efficient power transmission due to its universal joint configuration.

3. Vibration Damping: The Cardan coupling is more effective in absorbing shocks and vibrations during operation, resulting in reduced noise levels and improved stability in sawmill machinery compared to a disc coupling.

4. Durability: The Cardan coupling’s robust construction and reliable performance make it a durable choice for high-demand sawmill applications, offering enhanced longevity and minimal maintenance requirements.

5. Versatility: With its ability to accommodate angular misalignments and provide consistent torque transmission, the Cardan coupling is versatile and adaptable to a wide range of sawmill machinery configurations, making it a preferred choice for various operational needs.

About HZPT

Our company, HZPT, has been a trusted manufacturer and exporter of high-quality couplings since 2006. With 16 years of experience in design and production, we specialize in providing custom solutions for global customers and ensuring superior quality with CE and TUV certifications. At HZPT, we are committed to customer satisfaction and offer 24/7 service, competitive pricing, and innovative product designs tailored to market demand. Choose HZPT for reliable performance, exceptional service, and the best value for your sawmill coupling needs.