Product Description

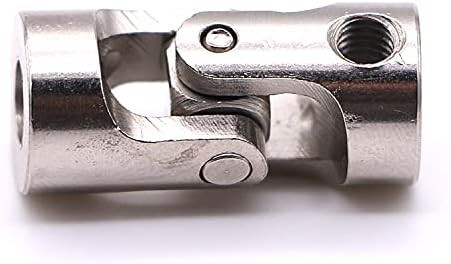

SWC-WD type coupling Nontelescopic Shorten Cardan Shaft Coupling

Product Description

SWC-WD-type cross shaft universal coupling is 1 of the most common coupling. With its characteristic structure enables not on the same axis or the axis angle greater or axial movement of a larger two-axis continuous constant angular velocity rotation, and reliably transmit torque and motion. Can be widely used in metallurgy, lifting, engineering, transportation, mining, oil, shipbuilding, coal, rubber, paper machinery and other heavy machinery industry, mechanical shafting transmitting torque.

Product Parameters

Advantages

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Packaging & Shipping

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2023-12-26