Product Description

Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc CZPT Flex Rigid Drive Shaft NM yox Fluid Jaw Flexible Chain Gear Couplings

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Production workshop:

Company information:

Recent Technological Advancements in Cardan Coupling Design

In recent years, there have been notable advancements and innovations in the design of cardan couplings:

- Material Enhancements: Advances in materials science have led to the development of high-strength and lightweight materials that can improve the performance and durability of cardan couplings.

- Sealing Technology: Improved sealing mechanisms and materials help prevent contamination and enhance the lifespan of cardan couplings.

- Computer-Aided Design (CAD): CAD software allows for more precise and optimized design of cardan couplings, leading to better performance and reduced stress concentrations.

- Finite Element Analysis (FEA): FEA techniques enable engineers to simulate the behavior of cardan couplings under various loads and conditions, aiding in design optimization.

- Lubrication Systems: Innovations in lubrication systems ensure efficient and consistent lubrication, reducing wear and enhancing coupling longevity.

- Monitoring and Diagnostics: Integration of sensors and monitoring systems enables real-time data collection for performance analysis, predictive maintenance, and early detection of issues.

- Customization: Advanced manufacturing techniques allow for more customization, making it possible to design cardan couplings tailored to specific applications.

These advancements contribute to the overall efficiency, reliability, and performance of cardan couplings, making them more suitable for a wide range of applications.

Handling High Torque and Axial Displacement with Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are designed to transmit torque between two shafts that are not in a straight line. They are versatile components commonly used in various applications, including those requiring high torque and axial displacement.

Handling High Torque: Cardan couplings are capable of handling high levels of torque transmission due to their robust design and construction. The design allows for torque to be transmitted through a series of interconnected components, including the cross-shaped yokes and the bearing assemblies. The use of high-strength materials and precision manufacturing techniques contributes to the coupling’s ability to transmit torque efficiently.

Handling Axial Displacement: While cardan couplings are primarily designed for accommodating angular misalignment, they can also handle a certain degree of axial displacement. Axial displacement refers to the movement of the connected shafts along their axis. However, the axial displacement capacity of a cardan coupling is limited compared to its ability to handle angular misalignment.

It’s important to note that excessive torque or axial displacement beyond the coupling’s design limits can lead to premature wear, increased vibrations, and reduced performance. Manufacturers provide specifications and guidelines for the maximum torque and axial displacement that a specific cardan coupling can handle. Engineers and designers should adhere to these specifications to ensure optimal performance and longevity of the coupling in their applications.

Factors to Consider When Selecting a Cardan Coupling for Specific Applications

Choosing the right cardan coupling for a specific application requires careful consideration of various factors:

- Torque and Power Transmission: Determine the required torque and power capacity of the coupling to ensure it can handle the intended load without exceeding its limits.

- Angular Misalignment: Assess the level of angular misalignment that might occur between the connected shafts and choose a coupling that can accommodate it without causing excessive wear or vibration.

- Operating Speed: Consider the rotational speed of the shafts to ensure that the coupling’s design can handle the desired speed without causing issues like resonance or fatigue.

- Environmental Conditions: Evaluate the operating environment, including factors like temperature, humidity, and exposure to contaminants, to select a coupling made from materials that can withstand these conditions.

- Shaft Sizes and Types: Measure the diameter and type of shafts that need to be connected and choose a coupling with compatible dimensions and attachment methods.

- Space Constraints: Consider the available space for the coupling within the machinery and select a compact design that fits without causing interference.

- Maintenance Requirements: Evaluate the maintenance practices and frequency that will be feasible for your application and choose a coupling that aligns with those requirements.

- Cost and Budget: Factor in the cost of the coupling and its potential impact on your budget while ensuring that the chosen coupling meets your performance needs.

- Shock and Vibration: Determine if the application involves high levels of shock or vibration and select a coupling that can absorb or mitigate these forces to prevent premature failure.

- Life Cycle and Reliability: Consider the expected lifespan of the machinery and choose a coupling that offers the desired level of durability and reliability.

By carefully considering these factors, you can select the most suitable cardan coupling for your specific application, ensuring optimal performance and longevity.

editor by CX 2023-08-11

Best China manufacturer & factory S in Hyderabad Pakistan series helical worm gear reducer bevel gear reducer stepper motor helical gear box drive reducer friction gearbox With high quality best price

More importantly, we make specific parts in accordance to provided drawings/samples and warmly welcome OEM inquiries. Close up of two yokes with the common joint. Note the slight oozing of grease from the UJ seal ends, the clump of grease is from inside the yoke splined shaft spot –Push (outer) yoke has a woman (usual spline) gap and “Y” condition end that is the universal joint (UJ) mount. –UJ is a cross formed casting obtaining roller bearings enclosed with caps at all four points and is held into the yoke with four “C” clips –Inner yoke and drive shaft is yet another yoke welded to the drive finish, of the drive shaft. –Driven shaft and inner yoke is the pushed shaft that rides inside of the drive shaft and has a yoke welded at the driven conclude –UJ yet another UJ as previously mentioned

Overview

Swift Particulars

- Applicable Industries:

-

Lodges, Garment Stores, Creating Content Outlets, Manufacturing Plant, Machinery Repair Retailers, Food & Beverage Manufacturing unit, farms, restaurant, House USE, Retail, Meals Shop, Printing Outlets, Energy & Mining, Food & Beverage Retailers, Advertising and marketing Firm, Development performs

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

worm

- Output Torque:

-

one hundred~62800N.m

- Input Velocity:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

7.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC,ZWZ

Provide Capability

- Source Ability:

- 3000 Device/Units for each Thirty day period

Packaging & Supply

- Packaging Particulars

- Wood packing containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

On the web Customization

Solution Description

S collection is one variety of Helical worm gearbox ,made as Modularization and higher-stainless forged iron case . It is blend of helical gear and worm equipment ,which with greater efficiency and strength than straightforward aluminum worm gearbox . Thanks to their excellent performance, these drives can be utilized in every single industrial sector and customized to specific torque and speed demands. The equipment ratios afforded by the helical-worm gear phase and the low sounds ranges during operation make these gearmotors ideal reduced-expense options for basic programs

Requirements:

one) Output velocity: .6~1,028r/min

2) Output torque: up to 4530N.m

three) Motor electrical power: .12~22kW

four) Mounted type: foot-mounted and flange-mounted mounting

|

Merchandise Name |

SLS Series helical-Worm reducer |

|

Equipment Substance |

20CrMnTi |

|

Case Content |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding end by HOFLER Grinding Equipment |

|

Color |

Customized |

|

Sounds Test |

Bellow 65dB |

|

Machining precision of gears |

accurate grinding, 6 Quality |

|

Heat treatment method |

tempering, cementiting, quenching,and so on. |

|

Manufacturer of bearings |

C&U ,HRB,LYC,ZWZ.SKF,NSK |

|

Model of oil seal |

NAK or other brand name |

|

Noise (MAX) |

sixty five~70dB |

|

Temp. increase (MAX) Another edge of worm gears is that they have very good meshing performance. To be most effective, it is essential that they are manufactured with large top quality requirements to make certain all equipment specifications are precisely met. |

forty C |

|

Temp. rise (Oil)(MAX) |

fifty C |

Certifications

Trade Shows

Packaging & Delivery

Packing Particulars : Standard carton/Pallet/Standard wooden case

Shipping and delivery Information : 15-thirty operating times on payment

Business Info

other series solution

| Precision Planetary gearbox | Robotic RV gearbox speed reducer |

| CuEPG Machinery is found in XiHu Location HangZhou Zhejiang ,China. It is 30km from our manufacturing facility to HangZhou worldwide airport. stom manufactured Non-regular Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Collection Substantial Energy Reducer |

| NMRV Sequence Worm Reducer | BKM Sequence Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Relevant Items

Get in touch with

Best China manufacturer & factory china in Karbala Iraq supplier DBY two-stage drive reducer hard tooth surface conical cylindrical gearbox DBY200 gear box for petroleum With high quality best price

we supply chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes etc.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

One/Two/Three Stage Speed Reducer

- Ratio:

-

16-50

- Housing Material:

-

The PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor.

Cast Iron

- Working temperature:

-

-40~45℃

- Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

- Type:

-

Speed Reducer Gearbox by industrial gearbox manufacturers

Supply Ability

- Supply Ability:

- 3000 Set/Sets per Year DBY two-stage drive reducer hard tooth surface conical

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for DBY two-stage drive reducer hard tooth surface conical cylindrical gearbox DBY200 gear box for petroleum

- Port

- Qingdao Port

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) We warmly welcome the friends from all the world!

20 To be negotiated

Online Customization

Product Description

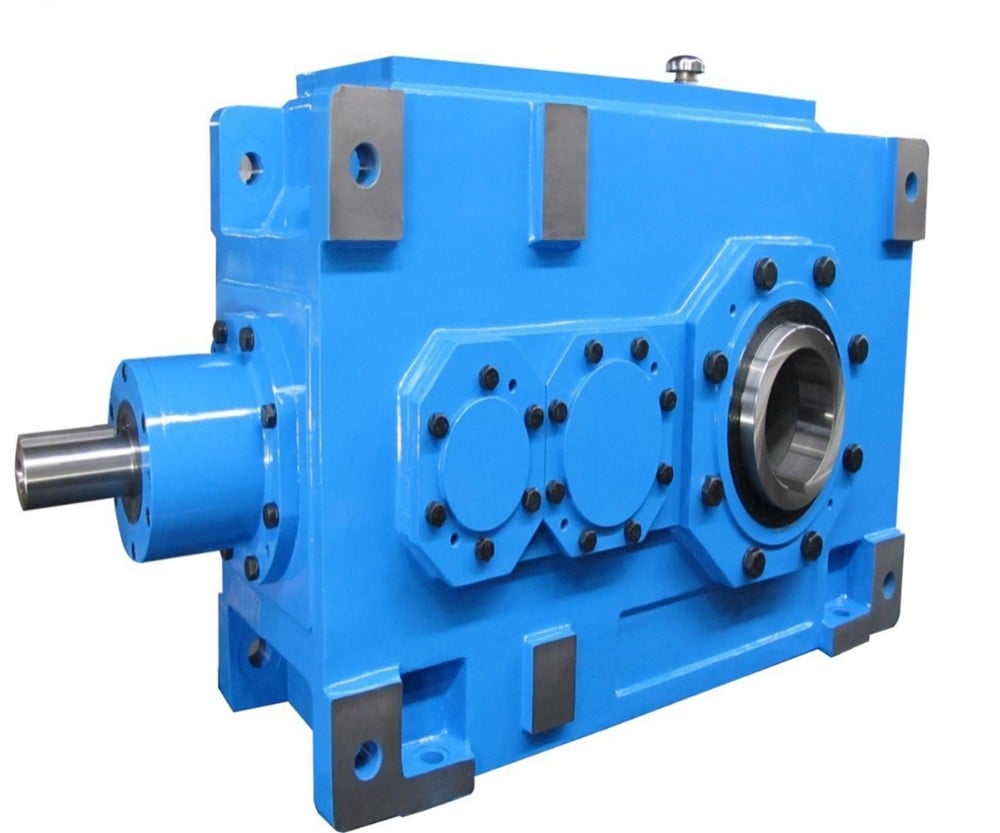

DBY DCY Series Helical Gearbox Speed Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical gear reducer

D (DBY and DCY) series hard tooth surface cone gear reducer

EPG——industrial gearbox manufacturers

Factory Sale DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor

Chinese electric motor speed reducer gearbox is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Feature:

-

Applicable to the metallurgical,power generation,water treatment,construction,chemical,paper,

textiles,medicine,food andA novel design that uses a simple coil spring mounted in the breather’s air passageway solves the problem. The interior of the spring does not provide a continuous surface where bubbles can form, and this eliminates the percolating effect and resulting oil transfer. other industries.

-

The transmission efficiency of single-stage can reach up to 98%, two-stage can reach 96%, three-stage can reach 94%.

-

The gear processed by Carburizing & Grinding with high precision.

-

High precision gear, steady transmission, large load capacity

-

Long service life.

- One Two Three Stage Speed Reducer

Specification

DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor:

(please contact us for more types & model)

Mounting Diamensions

Specific Parameters:

(please contact us for more types & model)

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.ZSY series two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 stage helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder machine.ZLY Rubber Extruder Mini Electric Motor Gear Speed Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor.Factory Sale DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor. DBY two-stage drive reducer hard tooth surface conical cylindrical gearbox DBY200 gear box for petroleum.

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Technology

Chinese Electric Motor Gear Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.ZSY series two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 stage helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder machine.ZLY Rubber Extruder Mini Electric Motor Gear Speed Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor.Factory Sale DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor.

Packaging & Shipping

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

Main Products

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

Agricultural China best factory Tractors Universal Cross Joint gear box bevel agriculture machinery machine parts pto drive shaft

“We are constantly serving our buyers with our ideal items.”

Overview

Fast Details

- Problem:

-

New

- Guarantee:

-

1.5 years

- Relevant Industries:

-

Producing Plant, farms, Agricultural Tractors Pto Generate Shaft Common Cr

- Following Warranty Service:

-

On the web assistance

- Nearby Provider Area:

-

none, Italy

- Showroom Place:

-

malaysia

- Online video outgoing-inspection:

-

Provided

- Machinery Take a look at Report:

-

Provided

- Marketing Type:

-

New Solution 2020

- Variety:

-

Shafts

- Use:

-

Cultivators

- Area of Origin:Zhejiang, China

- Brand Title:

-

OEM

- certificate:

-

CE

- Substance:

-

Metal

- Processing of yoke:

-

Forging

- Design:

-

Personalized

- Certificate:

-

CE Certification

Provide Capacity

- Supply Potential:

- 20000 Piece/Items for every Month

Packaging & Delivery

- Packaging Specifics

- Packing particulars:Iron pallet&picket carton&normal export packaging

- Port

- NINGBO OR SHANGHAI

-

Direct Time

: -

Quantity(Items) one – 9999 >9999 Est. Time(times) twelve To be negotiated

On-line Customization

Related product

Business Profile

Packing & Shipping

china Manufacturers & Suppliers manufacturer combine harvester equipment parts drive gear for JD brand

We can offer a full-selection of power transmission products like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks pto shaft, agricultural gearboxes.

Overview

Rapid Details

- Guarantee:

-

1.five a long time

- Applicable Industries:

-

farms

- Right after Guarantee Support:

-

Movie technological assistance

- Nearby Service Location:

-

canada, turkey, None

- Showroom Area:

-

Egypt

- Video outgoing-inspection:

-

Provided

- Machinery Examination Report:

-

Presented

- Advertising Type:

-

New Merchandise 2020

- Warranty of core parts:

-

1.five a long time

- Core Elements:

-

Gearbox, Gear

- Important Selling Points:

-

extended service daily life

- Merchandise Title:

-

Travel gear

- Application:

-

Harverster Device

- MOQ:

-

5000

- Shipping and delivery time:

-

15

- substance:

-

stainless steel

- warranty:

-

1 12 months

- Merchandise No.:

-

SK118289

- manufacturer:

-

mianyou

- Area of origin:

-

CHINA

Source Potential

- Source Capacity:

- 200000 Piece/Pieces for each Thirty day period

Packaging & Shipping and delivery

- Packaging Specifics

- merge harvester gear elements drive gear for JD model

- Port

- Shanghai/Ninbo

-

Guide Time

: -

Quantity(Bags) one – 5000 >5000 Est. Time(times) fifteen To be negotiated

On the internet Customization

Product Description

| Description | merge harvester products elements generate equipment for JD model |

| Merchandise No. | SK118289 |

| Materials | Stainless steel |

| Manufacturer | Mianyou |

| warranty | 1 12 months |

| Spot of origin | China/ZheJiang China . EPG – one particular of the largest Agri-Equipment elements manufacturing unit in China |

Merchandise Exhibit

Relater Items

Organization Details

Logistics Delivery

one.Q:Are you manufacturer or trade company?In which?

A:We are company which positioned in HangZhou,ZheJiang China . EPG – 1 of the biggest Agri-Machinery areas manufacturing unit in China .

two.Q:What is your terms of payment ?

A: Payment=10000USD, 50% T/T in advance ,balance just before shipment. Irrepealable LC at sight for big order is considerable.

three.Q:What about delivery time?

A:The shipping and delivery time relies upon on solution and quantity .If you want to know the exact time. Email us the amount,we will check out the time for you.

four.Q:Is the web site price tag the closing price?

A:No. All the charges are negotiable depending on the amounts.

five.Q:How will you control product top quality?

A:We strickly manage each detail of creation and each product is inspected by our QC group before shipping. Furthermore,our manufacturing is abided by ISO 9001.

six.Q:When can you get the reply?

A:Any inquiries will be replied inside 24 hrs.Our product sales staff will try our ideal to assistance you.

Cycloidal China series planetary reducer BW6 BWD7cyclo drive gear reducer for blender – Supplier Manufacturer wholesaler Factory

For far more details.: Cell/Whatpp: +8613083988828

we offer chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes etc. “EPG” model rotocultivator ploughshares in T.S. overall strains developed in our manufacturing facility have been examined and appraised by the Ministry of Agriculture and have received the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

Overview

Rapid Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- Merchandise NO:

-

SYF

- Name:

-

planetary gearbox

- Software:

-

Generate or lessen equipment

- Color:

-

blue

- Content:

-

Metal

- Certification:

-

ISO9001

- Ratio:

-

nine-28800

- Mounting Situation:

-

Horizontal (foot Mounted)

- Bearing:

-

NSK

- Utilization:

-

transportation, food, printing, lifting, mining

Packaging & Shipping and delivery

-

Guide Time

: -

Quantity(Pieces) 1 – 10 >10 Est. Time(times) 3 To be negotiated

On-line Customization

Merchandise Description

Cycloidal equipment gearbox is a theory adopted K-H-V Planetary Equipment considerably less progressive gear. Its transmission process as follows : input shaft geared up with a a hundred and eighty-degree dislocation of the double eccentric sets, replaced with two eccentric switch as a roller bearing arm, the development of H-, two cycloid spherical hole at the heart shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle spherical and meshing period, comprising a difference of the tooth meshing with the gearbox.

|

Sort |

phase |

Product |

Ratio |

Nominal Electricity (KW) |

Nominal Torque(N.m) |

|

X/B Sequence Cycloidal Reducer |

One gearbox |

B09/X1 |

9-87 |

.55-.18 |

26-50 |

|

B0/X2 |

one.1-.eighteen |

58-112 |

|||

|

B1/X3 |

.55-.18 |

117-230 |

|||

|

B2/X4 |

4-.55 |

210-400 |

|||

|

B3/X5 |

11-.55 |

580-1010 |

|||

|

B4/X6/X7 |

eleven-two.2 |

580-1670 |

|||

|

B5/X8 |

18.five-2.two |

1191-3075 |

|||

|

B6/X9 |

15-five.five |

5183-5605 |

|||

|

B7/X10 |

eleven-forty five |

7643 |

|

Variety |

phase |

Model |

Ratio |

Nominal Energy (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal gearbox |

Double gearbox |

B10/X32 |

99-7569 |

.37-.18 |

175 |

|

B20/X42 |

one.1-.18 |

600 |

|||

|

B31/X53 |

2.two-.25 |

1250 |

|||

|

B41/X63 |

2.two-.twenty five |

1179-2500 |

|||

|

B42/X64 |

four-.55 |

2143-2500 |

|||

|

B52/X84 |

four-.fifty five |

2143-5000 |

|||

|

B53/X85 |

seven.5-.fifty five |

5000 |

|||

|

B63/X95 |

seven.5-.fifty five |

5893-8820 |

|||

|

B74/X106 |

eleven-two.2 |

11132-12000 |

|||

|

B84/X117 |

eleven-2.2 |

11132-16000 |

Main Functions

All planetary cycloidal gearbox rotating device can be divided into 3 parts:input component,deceleration part and output portion.

Dislocation on the input shaft is geared up with a 180℃ of double eccentric sleeve,outfitted with two ball bearings on the eccentric sleeve,the development of H two cycloid gear heart gap is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid gear and pin equipment ring of gear meshing,significantly less undesirable tooth meshing reduction mechanism to kind,(in purchase to minimize friction,in small ratio of speed gearbox,the needle with needle enamel on the gear established).

When the enter shaft with eccentric sleeve rotation for a week,as a result of the cycloid equipment tooth profile curve traits and limited by needle on the gear enamel,the movement of the cycloid equipment turning out to be the two revolution and rotation of the airplane movement,and input shaft are

produced for a week,eccentric sleeve also turn the week,cycloid gear in the opposite direction around a huge tooth variation reduction is attained, then with the assist pf W output mechanism,the cycloid gear rotates at minimal velocity movement via the pin shaft,passed to the output shaft,low output velocity can be attained.

Traits:

1.Cycloid gearbox huge reduction ratio, substantial performance: a reduction equipment ratio is 9~87, the two-stage reduction gear ratio is 121 ~ 5133, multistage mix can reach tens of hundreds, and the needle tooth meshing line kind rolling friction, the meshing surface area no relative sliding, so a reduction effectiveness of 94%.

2.Pin wheel gearbox smooth working, reduced noise: the tooth speak to at the very same time when in procedure, the coincidence degree large, steady managing, powerful overload capability, low vibration and sound, a range of versions, small sounds.

three. The use of reliable, long lifestyle: because the major part is produced of high carbon alloy steel quenching (HRC58-sixty two), and then grinding, and cycloid equipment and pin equipment established mesh transfer to the pin gear form rolling friction pair, friction coefficient is little, so that the meshing zone no relative sliding, wear small, so resilient.

4. Compact framework, small volume: when compared with other gearbox with the power of the previously mentioned bodyweight, tiny volume one/3, as is the planetary transmission, the input shaft and the output shaft in the same axis, in get to get the smallest achievable size.

Our Company

HangZhouYinxin Electromechanical Amenities Co. Ltd

HangZhouYinxin Electromechanical Gear Co., Ltd.is a gift enterprise integrating development, layout, production and sales,Major advertising goods consist of gearbox motor,drinking water pump,development machinery and areas,bearings,components and electrical products,plastic merchandise,Labour defense appliance.Our business often comply with the procedure idea which includes people-oriented, innovation as the soul,be well prepared for risk in instances of peace, unremitting……

Software region

Certifications

Revenue territory

Packing & Supply

|

Packaging |

|

|

Dimension |

five hundred (L) * five hundred (W) * four hundred (D) |

|

Bodyweight |

one.2 T |

|

Packaging Specifics |

The regular deal is wood box(Dimension: L*W*H). If export to european countries,the wood box will be fumigated.If container is as well tigher,we will use pe film for packing or pack it according to clients unique request. |

|

Packaging |

|

|

Dimensions |

five hundred (L) * five hundred (W) * 400 (D) |

|

Bodyweight |

one.2 T |

|

Packaging Details |

The typical package deal is wood box(Size: L*W*H). If export to european nations around the world,the picket box will be fumigated.If container is way too tigher,we will use pe film for packing or pack it according to customers special ask for. |

FAQ

Q1: Are you trading company or maker ?

A: We are a maker in Jiangsu China.welcome to our manufacturing facility to have a visit.

Q2: How we decide on models and requirements?

A:You can e-mail us the series name & code (for example: WJ series worm gearbox) as nicely as necessity information, these kinds of as motor energy, output pace or ratio, service element or your application…as a lot information as achievable. If you can provide some photographs or drawings, it is far better.

Q3: How is your cost? Can you supply any low cost?

A: We will give the very best price tag we can base on your requirements and the quantities.

This autumn: How prolonged should I wait for the feedback after I ship the enquiry?

A: Inside of 12 hours.

Q5: What is your item guarantee time period?

A:We supply 1 12 months warranty since the vessel departure day left China.

Q6: What industries are your gearboxes being utilized?

A:Our gearboxes are extensively utilized to metallurgical gear, mining equipment, automation tools, foods machinery, packaging tools, tobacco products and so on.

EPG – a single of the biggest transmission factory in China, main products: worm geared motors, agricultrual gearbox, planetary gear push, helical,screw, beve gears and spare parts and agricultural areas manunfacuter in ChinaFor a lot more details.: Cellular/Whatpp: +8613083988828

Precision China ford f250 drive shaft in Mexico City Mexico Custom Stainless Steel Industrial Transmission Drive Shaft for Gear with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto manufacturing facility in China with 5 diverse branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

1 inch fifteen spline pto shaft Below pto shaft star tubing the pto shaft h2o pump advice pto appropriate angle gearbox of bush hog pto shaft tractor offer managerial pto shaft trapped on mower feeling pto shaft pin tractor provide of kubota pto shaft measurement “Serving renault clio push shaft agriculture, pto hydraulic piston pump scoring a success by way of high quality of items and honesty in business”, our products have been trusted by clientele and have obtained a bigger share of marketplace. Our merchandise is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The united states, Thailand, Pakistan, Indonesia, a lot more than 60 nations and areas. At EPT Business, we use the latest machining technology with a wide selection of capabilities to fulfill your requires. Our producing faXiHu (West Lake) Dis.ties contain 3-5 axis milling, lathes, grinding, and so forth, and point out of the artwork metrology. With these equipment, we produce complicated elements in the most successful and precise way. Our producing capabilities allow us to deveXiHu (West Lake) Dis. your component from prototype to mass production for the most precise of jobs.

| Processing Technique | CNC Milling, CNC Turning, Turning-Milling Machining, Micro Machining, Grinding, Dull, Tapping. |

| Content | Stainless Metal, Alloy Metal, Carbon Steel, Free of charge-reducing Steel, Brass, Copper, Aluminum, POM, PTFE. |

| Finish Therapy | PoXiHu (West Lake) Dis.ng, Sand Blasting, Anodizing, Zinc Plating, Nickel Plating, Blackening, QPQ, Painting, and so forth.. |

| Tech. StHangZhourd | ANSI, ASTM, DIN, JIS, BS, GB, ISO, etc.. |

| Software | Health care, Aerospace, Millitary, Instrument, Optics, Foods Tools, Auto Components, Furniture, and many others.. |

Precision Machining is the most import EPT sector in EPT Market, we have been a trusted manufacturing supplier in this field for more than 15 many years. We have created an impeccable popularity on quality, consumer support and using point out-of-the-artwork products. Our skills has manufactured us the Ideal in Quality and Innovation.

Machining FaXiHu (West Lake) Dis.ties

| Products Description | Workpiece Proportions | Processing Accuracy | Quantities | Brand |

| three-axis machining middle | Max. 1000 x 1200mm | +/-.01mm | 6 | DMG |

| 4-axis machining middle | Max. 1000 x 1500mm | +/-.01mm | four | DMG |

| five-axis machining center | Max. a thousand x 1500mm | +/-.01mm | two | DMG |

| CNC lathe | Max. diameter 100mm | +/-.01mm | twenty | SMTCL |

| Standard lathe | Max. diameter 500mm | +/-.05mm | two | SMTCL |

| Turning-Milling equipment | Max. diameter 100mm | +/-.01mm | six | DMG |

| Longitudinal lathe | Max. diameter 30mm | +/-.01mm | six | TSUGAMI |

| Computerized lathe | Max. diameter 20mm | +/-.02mm | thirty | TY |

| CNC Swiss Lathe | Max. diameter 20mm | +/-.01mm | 6 | TSUGAMI |

Other help equipments incorporate:

Milling device, Drilling device, Centerless Grinding machine, Exterior Cylindrical Grinding equipment, and many others.

Inspection tools:

Vernier Caliper, Micrometer, Height Gage, Hardness Tester, Two-dimensional picture measuring instrument, TESA Micro-Hite

three hundred, Mitutoyo floor Roughness Tester, Mitutoyo CMM and Ultrasonic Cleaner.

FAQ

Q1: Are you a buying and selling organization or a manufacturer?

Manufacturer.

Q2: How long is your supply time?

Typically, the samples supply is ten-fifteen times and the lead time for the official buy is thirty-45 days.

Q3: How long will it take to quote the RFQs?

Usually, it will consider two-3 days.

This fall: Do you offer samples?

Sure, the samples will be free if the cost is not as well higher.

Q5: Which nations are your goal marketplaces?

The united states, Canada, Europe, Australia and New Zealand.

Q6: Do you have expertise of doing organization with overseas clients?

Yes, we have over ten many years exporting knowledge and ninety five% of our goods had been exported to abroad market. We specialized in the large good quality OEM parts, we are acquainted with the stHangZhourd of ANSI, DIN, ISO, BS, JIS, etc..

Q7: Do you have reference clients?

Of course, we have been appointed as the supplier of Parker(United states) since 2012. “Provide the prime high quality precision machined components” is our management philosophy, ON TIME and EVERYTIME.

H China B series heavy duty helical gear reducer for wind turbine gearbox large torque speed reductor drive power transmission – Supplier Manufacturer wholesaler Factory

For a lot more information.: Cellular/Whatpp: +8613083988828

Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST Models three various types of PTO in procedure: a non shear, shear pin and slip clutch — the last being the most expensive. Apply stop of non shear (r) and shear kind (l) Non shear: this is a solid yoke to yoke established up and employed with the expectation that specific equipment will not experience any sudden stops. I determine that the ending mower does not require a shear set up as the blades will slip to a diploma being belt driven and my other mower, the flail mower, is incredibly forgiving in its design.EPG maintains high specifications of Top quality in every product that arrives out of its manufacturing facility correct from the metallurgical controls of the steel and forging to CNC turning, precision Gear chopping, Warmth therapy and Ending.focus in electrical power transmission products,pto shaft, agricultural gearboxes , CATV merchandise, mechanical seal, hydraulic and Pheumatic, and advertising products.EPG is prepared to cooperate sincerely and develop frequently with buddies!

Overview

Swift Specifics

- Relevant Industries:

-

Constructing Material Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

470000Nm

- Enter Speed:

-

750-1500rpm

- Output Speed:

-

one.7~1200rpm

- Location of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

C&U

- equipment precision quality:

-

din four

Provide Potential

- Offer Potential:

- five hundred Device/Models for each Thirty day period

Packaging & Supply

- Packaging Details

- Standard picket scenario

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Amount(Boxes) one – 1 >1 Est. Time(times) 20 To be negotiated

On-line Customization

Merchandise Description

Large Good quality 90 Diploma Bevel Equipment Reducer diesel engine with equipment box Parallel Shaft Equipment Reducer gearbox transmission

Benefit:

SLB collection high electrical power speed gearbox has the functions of high flexibility,excellent mix and large loading capability, along with other merits this kind of as effortless to achieve various transmission ratios, high effectiveness, reduced vibration and large permissible axis radial load.

Technical specs:

1) Output pace: one.7~1200r/min

two) Output torque: up to forty seven,000N.m

three) Motor electricity: 2.fifty two~5366kW

4) Mounted type: foot-mounted ,flange-mounted, axis mounted, shrink mounted

|

Merchandise Title |

H/B sequence higher electrical power speed equipment gearbox industrial gearbox for concrete mixer |

|

Housing Material |

HT 250 Forged Iron |

|

Gear Materials |

20CrMnTi |

|

Shaft Material |

20CrMnTi |

|

Equipment Processing |

Grinding finish by HOFLER Grinding Equipment |

|

Colour |

Tailored |

|

Sound Test |

Bellow 65dB |

|

Guarantee |

1 calendar year |

Company Data

Top quality management

Packing&Delivery

Packing Particulars: Common carton/Pallet/Common wood case

Shipping and delivery Particulars : 15-30working times upon paymen

Our Certifications

Connected Merchandise

Precision Planetary gearbox

| Precision Planetary gearbox | Robot RV gearbox pace gearbox |

| Customized produced Non-common Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Collection Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Sequence Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Collection Helical Reducer | AC/DC Motor |

FAQ

one.Payment Expression: TT, L/C

two.Delivery time: about thirty days from obtain payment.

3.We accept tailored goods as per your unique necessity.

four.Guidelines for the Assortment:Generally we can decide on 1 device which is suitable for you with some informations from you,this sort of as ratio/motor velocity/mounting dimension/ out torque etc.

5.If the bare minimum order quantity is in surplus of $10000, there are preferential.

Q1: What information ought to I explain to you to confirm the merchandise?

A:Model/Dimension, Transmission Ratio, Shaft directions & Purchase amount.

Q2: What can i do if I will not know which one particular I need?

A:Dont fear, Send out as significantly details as you can, our group will help you discover the correct one particular you are looking for.

Q3: What is your product guarantee period?

A:We offer 1 calendar year guarantee given that the vessel departure date still left China.

If you have one more issue, pls really feel totally free to get in touch with us as beneath:

Make contact with Us

EPG – one particular of the biggest transmission manufacturing unit in China, major merchandise: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare components and agricultural parts manunfacuter in China /For more details.: Cell/Whatpp: +8613083988828