Product Description

SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Description:

SWC-WD-type cross shaft universal coupling is 1 of the most common coupling. With its characteristic structure enables not on the same axis or the axis angle greater or axial movement of a larger two-axis continuous constant angular velocity rotation, and reliably transmit torque and motion. Can be widely used in metallurgy, lifting, engineering, transportation, mining, oil, shipbuilding, coal, rubber, paper machinery and other heavy machinery industry, mechanical shafting transmitting torque.

Advantages:

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Product parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Signs of Wear or Damage in a Cardan Coupling and Detection Methods

Over time, cardan couplings can experience wear or damage that may impact their performance. Some common signs of wear or damage include:

- Vibration: Excessive vibration during operation can indicate misalignment or worn components in the cardan coupling.

- Noise: Unusual noises such as clunking, knocking, or rattling can indicate worn bearings or other components.

- Increased Play: If there is noticeable play or backlash in the coupling, it may suggest worn or loose components.

- Reduced Performance: A decrease in torque transmission or power transfer efficiency can indicate wear in the coupling.

- Leakage: In the case of lubricated cardan couplings, leakage of lubricant may occur due to worn seals or damaged components.

To detect these signs of wear or damage, various methods can be employed:

- Visual Inspection: Regularly inspect the coupling for any visible signs of wear, corrosion, or damage.

- Vibration Analysis: Use vibration analysis tools to monitor vibration levels and detect any irregularities.

- Noise Analysis: Listen for unusual noises during operation, which may indicate worn or misaligned components.

- Torque Measurement: Monitor the torque transmitted through the coupling and compare it with expected values.

- Play Measurement: Check for any play or backlash in the coupling by manually moving the shafts.

- Lubricant Analysis: Analyze the condition of the lubricant for any contamination or signs of wear.

Regular maintenance and inspections are crucial for detecting and addressing wear or damage in cardan couplings before they lead to more severe issues or failures.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-04-17

China Hot selling SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Product Description

SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Description:

SWC-WD-type cross shaft universal coupling is 1 of the most common coupling. With its characteristic structure enables not on the same axis or the axis angle greater or axial movement of a larger two-axis continuous constant angular velocity rotation, and reliably transmit torque and motion. Can be widely used in metallurgy, lifting, engineering, transportation, mining, oil, shipbuilding, coal, rubber, paper machinery and other heavy machinery industry, mechanical shafting transmitting torque.

Advantages:

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Product parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-04-15

China manufacturer & factory supplier for wenzhou in West Yorkshire United Kingdom coaxial transmission speed reducer motor engine spiral transmission lifting equipment steering gear box lifting jack With high quality best price & service

ISO 9001:2015 certified producer and distributor of roller chains. Kinds of roller chains contain ASME/ANSI standard chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, totally free-movement chains, specialty chains and British common chains. ASME/ANSI standard chains are obtainable in massive and tiny pitch, double pitch and leaf styles. Roller chains are utilised in meals packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and electricity transfer applications.We have exported our goods to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states of america, Canada, and many others.

Overview

Quick Particulars

- Applicable Industries:

-

Manufacturing Plant, Machinery Fix Stores, Foods & Beverage Factory, Farms

- Area of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Velocity:

-

1400rpm

- Output Speed:

-

fourteen-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Place:

-

Foot Mounted

- Bearing:

-

LYC,SKF

Source Potential

- Supply Capacity:

- five hundred Unit/Models for every Month

Packaging & Shipping and delivery

- Packaging Particulars

- Wood containers , Cantons packed in 1 pallet

Our goods is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, more than sixty countries and regions.

- Port

- Ningbo Port, Shanghai Port

On-line Customization

Item Description

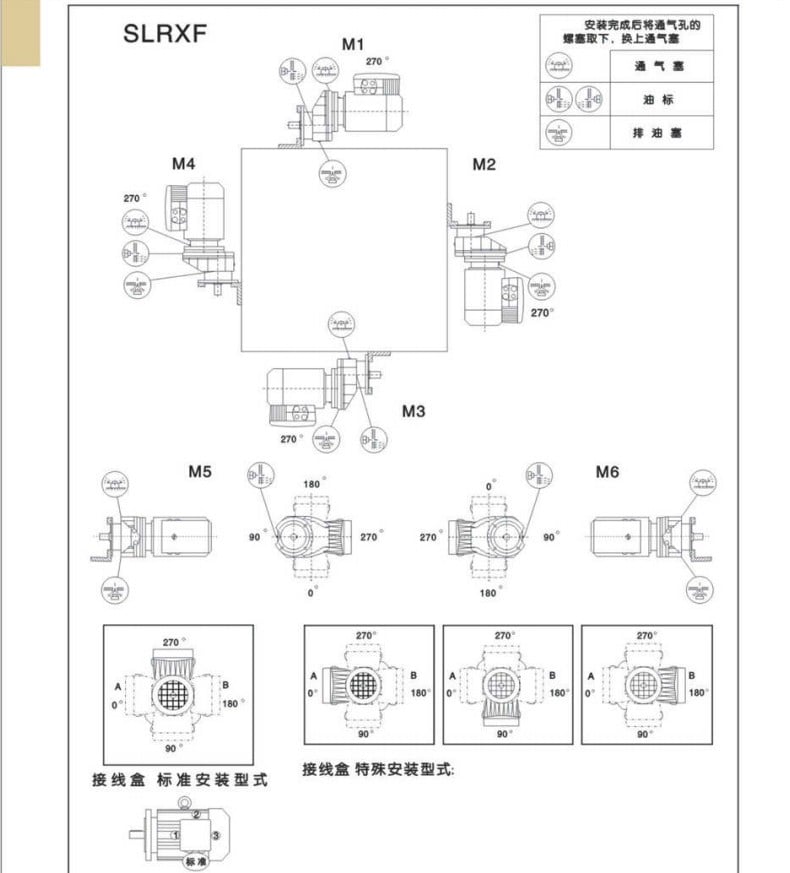

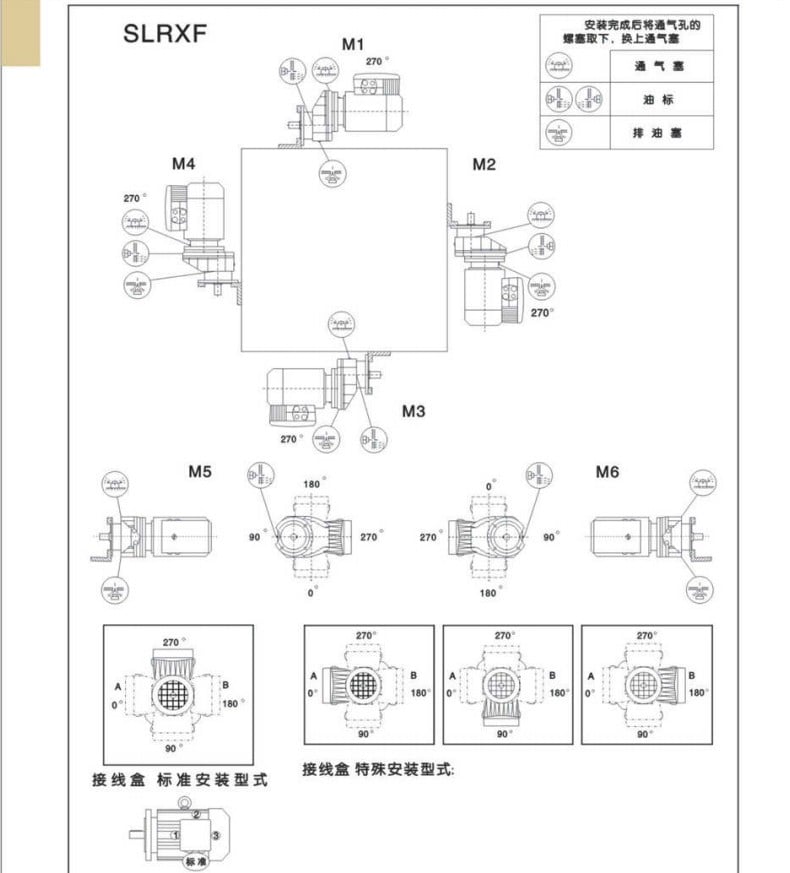

SLR helical reducer has the features of large versatility,very good blend and weighty loading functionality, alongside with other merits this kind of as straightforward to achieve a variety of transmission ratios, high performance, reduced vibrationand large permissible axis radial load. This series can not only be combined with a variety of kinds of reducers and variators and meet the requirements, but also beadvantage of localization of relevant transmission tools.

Requirements:

1) Output pace: .6~1,028r/min

2) Output torque: up to eighteen,000N.m

three) Motor energy: .eighteen~160kW

4) Mounted kind: foot-mounted and flange-mounted mounting

|

Product Identify |

SLR Collection Rigid Tooth helical reducer |

|

Equipment Material |

20CrMnTi |

|

Situation Substance |

HT250 |

|

Shaft MaterialA power just take-off or power takeoff (PTO) is any of several strategies for having power from a power supply, such as a operating motor, and transmitting it to an application this kind of as an attached apply or separate device. |

20CrMnTi |

|

Equipment Processing |

Grinding end by HOFLER Grinding Equipment |

|

Color |

Custom-made |

|

Sounds Check |

Bellow 65dB |

Certifications

Trade Exhibits

Packaging & Transport

Packing Details : Standard carton/Pallet/Standard wooden case

Shipping Specifics : 15-thirty woOur stepper and BLDC motors, linear actuators and linear positioning drives, in dimensions commencing at 10 mm, collectively with a variety of gearboxes and encoders, blend into a modular system with above 4000 attainable combinations. In addition, you can pick from a selection of shaft, flange and connector varieties that quickly and reliably link to current unit architecture. The efficiency and resonance actions of EPG motors is optimized by smart motor controllers that meet the latest technological innovation expectations.rking times on payment

Firm Info

other collection item

| Precision Planetary gearbox | Robotic RV gearbox pace reducer |

| Personalized created Non-normal Gearbox | UDL Collection Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series High Electricity Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Related Products

Speak to

China manufacturer & factory supplier for SMR in Larkana Pakistan TXT shaft mounted gearbox speed reducer drive adjustable gearbox tractor gearbox parts power transmission With high quality best price & service

Roller Chain Elements Every chain is related at the finishes to form a comprehensive circle or chain loop by a master connecting url. Cotter plates or spring clips maintain the connecting link’s pins from operating free.If you are intrigued in any of our products or would like to go over a prospective order, make sure you feel cost-free to contact us.

Overview

Rapid Particulars

- Applicable Industries:

-

Constructing Content Stores

- Gearing Arrangement:

-

Helical

- Output Torque:

-

256-7449N.m

-

In get to uncover a ideal gearbox for your application from the general phase, our on the web SIZING ASSISTANT design and style tool is excellent: primarily based on your application data or the sought after motor, a appropriate gearbox can be picked from our portfolio and geometry adjustment executed in a number of seconds. Upon need, we can also send out you a ask for for quotation directly on the web.

- Input Velocity:

-

1400rpm

- Output Speed:

-

one hundred~400RPM

- Area of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

-

Coloration:

Adhering to “Survival by Top quality, Development by Technologies & Credit score”, The company will constantly increase product efficiency to satisfy the growing client needs in the demanding fashion of operate. -

Blue / Gray / Client requirement

Offer Ability

- Supply Ability:

- 2000 Established/Sets per Month

Packaging & Shipping

- Packaging Particulars

- Picket scenario for every pc + numerous pcs in massive wooden case

- Port

- Shanghai/Ningbo port

-

Direct Time

: -

Quantity(Bins) 1 – one >1 Est. Time(days) 20 To be negotiated

Online Customization

Specification

SMR / TXT shaft mounted gearbox pace reducer push adjustable gearbox tractor gearbox elements electrical power transmission

Conveyor & Material Managing

Mining & Quarry

Characteristic

1) All gears are warmth handled and mounted to accomplish lower noise and high output

2) Mounting dimensions are interchangeable with Fenner

|

SMR Design No. |

Output Shaft Bore [mm] |

Ratio(i) |

|

|

Standard |

Different |

||

|

B |

Φ30 |

Φ40 |

five:1 13:one twenty:1 |

|

C |

Φ40 |

Φ50 |

|

|

D |

Φ50 |

Φ55 |

|

|

E |

Φ55 |

Φ65 |

|

|

F |

Φ65 |

Φ75 |

|

|

G |

Φ75 |

Φ85 |

|

|

H |

Φ85 |

Φ100 |

|

|

J |

Φ100 |

Φ120 |

|

Company info

Good quality management

Packing

Shipping

FAQ

Q1: What data should I inform you to verify the solution?

A: Design/Size, Transmission Ratio, Shaft instructions & Purchase quantity.

Q2: What can i do if I do not know which one I neSlip clutch type on the rotary tiller, once more slight oozing of grease on the UJ, do not grease the clutch these operate dry and ought to be “slipped” at the very least as soon as a yr to avert rusting togethered?

A: Will not fret, Send as a lot information as you can, our team will assist you discover the proper 1 you are searching for.

Q3:What is your item guarantee period of time?

A:We offer you one particular 12 months warranty considering that the vessel departure date remaining China.

If you have another question, pls truly feel free to contact us as beneath:

Make contact with us

Newin Custom made in China – replacement parts – in Mexico City Mexico Bac Series Cooling Tower Aluminium Alloy Speed Reducer Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Newin Bac Series Cooling Tower Aluminium Alloy Speed Reducer Pulley

Aluminium Alloy Speed Reducer Pulley

Material: Aluminium Alloy

Belt type reduction drive

At present, the main transmission methods for mechanical draft cooling tower are multi-polar direct drive motor, belt type reduction drive, gear reducer drive, hydraulic turbine drive etc. Belt type reduction drive is widely application, through the tension in the pulley of the driving wheel and driven wheel belt for the power transfer to a mechanical transmission, it has a simple structure, stable transmission, can buffer vibration absorption, can be in large axial spacing between shaft and transmission power, low cost, without lubrication, easy maintenance and EPT characteristics, widely used in the cooling tower and a number of mechanical equipment.

Application: Marley cooling tower, square cooling tower,bac cooling tower, round type cooling tower etc.

For more about the belt pulley, please visit to our website: For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Best China manufacturer & factory S in Hyderabad Pakistan series helical worm gear reducer bevel gear reducer stepper motor helical gear box drive reducer friction gearbox With high quality best price

More importantly, we make specific parts in accordance to provided drawings/samples and warmly welcome OEM inquiries. Close up of two yokes with the common joint. Note the slight oozing of grease from the UJ seal ends, the clump of grease is from inside the yoke splined shaft spot –Push (outer) yoke has a woman (usual spline) gap and “Y” condition end that is the universal joint (UJ) mount. –UJ is a cross formed casting obtaining roller bearings enclosed with caps at all four points and is held into the yoke with four “C” clips –Inner yoke and drive shaft is yet another yoke welded to the drive finish, of the drive shaft. –Driven shaft and inner yoke is the pushed shaft that rides inside of the drive shaft and has a yoke welded at the driven conclude –UJ yet another UJ as previously mentioned

Overview

Swift Particulars

- Applicable Industries:

-

Lodges, Garment Stores, Creating Content Outlets, Manufacturing Plant, Machinery Repair Retailers, Food & Beverage Manufacturing unit, farms, restaurant, House USE, Retail, Meals Shop, Printing Outlets, Energy & Mining, Food & Beverage Retailers, Advertising and marketing Firm, Development performs

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

worm

- Output Torque:

-

one hundred~62800N.m

- Input Velocity:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

7.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC,ZWZ

Provide Capability

- Source Ability:

- 3000 Device/Units for each Thirty day period

Packaging & Supply

- Packaging Particulars

- Wood packing containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

On the web Customization

Solution Description

S collection is one variety of Helical worm gearbox ,made as Modularization and higher-stainless forged iron case . It is blend of helical gear and worm equipment ,which with greater efficiency and strength than straightforward aluminum worm gearbox . Thanks to their excellent performance, these drives can be utilized in every single industrial sector and customized to specific torque and speed demands. The equipment ratios afforded by the helical-worm gear phase and the low sounds ranges during operation make these gearmotors ideal reduced-expense options for basic programs

Requirements:

one) Output velocity: .6~1,028r/min

2) Output torque: up to 4530N.m

three) Motor electrical power: .12~22kW

four) Mounted type: foot-mounted and flange-mounted mounting

|

Merchandise Name |

SLS Series helical-Worm reducer |

|

Equipment Substance |

20CrMnTi |

|

Case Content |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding end by HOFLER Grinding Equipment |

|

Color |

Customized |

|

Sounds Test |

Bellow 65dB |

|

Machining precision of gears |

accurate grinding, 6 Quality |

|

Heat treatment method |

tempering, cementiting, quenching,and so on. |

|

Manufacturer of bearings |

C&U ,HRB,LYC,ZWZ.SKF,NSK |

|

Model of oil seal |

NAK or other brand name |

|

Noise (MAX) |

sixty five~70dB |

|

Temp. increase (MAX) Another edge of worm gears is that they have very good meshing performance. To be most effective, it is essential that they are manufactured with large top quality requirements to make certain all equipment specifications are precisely met. |

forty C |

|

Temp. rise (Oil)(MAX) |

fifty C |

Certifications

Trade Shows

Packaging & Delivery

Packing Particulars : Standard carton/Pallet/Standard wooden case

Shipping and delivery Information : 15-thirty operating times on payment

Business Info

other series solution

| Precision Planetary gearbox | Robotic RV gearbox speed reducer |

| CuEPG Machinery is found in XiHu Location HangZhou Zhejiang ,China. It is 30km from our manufacturing facility to HangZhou worldwide airport. stom manufactured Non-regular Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Collection Substantial Energy Reducer |

| NMRV Sequence Worm Reducer | BKM Sequence Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Sequence Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Relevant Items

Get in touch with

Best China manufacturer & factory china in Karbala Iraq supplier DBY two-stage drive reducer hard tooth surface conical cylindrical gearbox DBY200 gear box for petroleum With high quality best price

we supply chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes etc.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

One/Two/Three Stage Speed Reducer

- Ratio:

-

16-50

- Housing Material:

-

The PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor.

Cast Iron

- Working temperature:

-

-40~45℃

- Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

- Type:

-

Speed Reducer Gearbox by industrial gearbox manufacturers

Supply Ability

- Supply Ability:

- 3000 Set/Sets per Year DBY two-stage drive reducer hard tooth surface conical

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for DBY two-stage drive reducer hard tooth surface conical cylindrical gearbox DBY200 gear box for petroleum

- Port

- Qingdao Port

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) We warmly welcome the friends from all the world!

20 To be negotiated

Online Customization

Product Description

DBY DCY Series Helical Gearbox Speed Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical gear reducer

D (DBY and DCY) series hard tooth surface cone gear reducer

EPG——industrial gearbox manufacturers

Factory Sale DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor

Chinese electric motor speed reducer gearbox is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Feature:

-

Applicable to the metallurgical,power generation,water treatment,construction,chemical,paper,

textiles,medicine,food andA novel design that uses a simple coil spring mounted in the breather’s air passageway solves the problem. The interior of the spring does not provide a continuous surface where bubbles can form, and this eliminates the percolating effect and resulting oil transfer. other industries.

-

The transmission efficiency of single-stage can reach up to 98%, two-stage can reach 96%, three-stage can reach 94%.

-

The gear processed by Carburizing & Grinding with high precision.

-

High precision gear, steady transmission, large load capacity

-

Long service life.

- One Two Three Stage Speed Reducer

Specification

DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor:

(please contact us for more types & model)

Mounting Diamensions

Specific Parameters:

(please contact us for more types & model)

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.ZSY series two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 stage helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder machine.ZLY Rubber Extruder Mini Electric Motor Gear Speed Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor.Factory Sale DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor. DBY two-stage drive reducer hard tooth surface conical cylindrical gearbox DBY200 gear box for petroleum.

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Technology

Chinese Electric Motor Gear Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.ZSY series two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 stage helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder machine.ZLY Rubber Extruder Mini Electric Motor Gear Speed Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor.Factory Sale DCY Series Chinese Speed Reducer Gearbox 1:50 Ratio with Stepper Motor.

Packaging & Shipping

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

Main Products

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

Best China manufacturer & factory India in Nonthaburi Thailand sell like hot cakes horizontal gear units helical gearbox crane duty gear boxes zq 500 zq500 speed reducer for crane With high quality best price

EPG has set up a complete set of quality management system which is provided with advanced inspection and test equipment.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Rated Power:

-

0.12~200kw

- Product name:

-

JZQ gear box

- Product Keywords:

-

gearbox for metal flattening machine

To address these sealing and efficiency issues, Emerson Power Transmission (EPT) developed several design and manufacturing recommendations. The resulting gearboxes tend to run coThe PTO shaft is the mechanical device that transfer the power from the tractor to the agricultural implement. The PTO shaft is made of two joints connected by telescopic tubes: one joint connects the outer tube of the PTO shaft with the tractor power take-off , the other joint connects the inner tube of the PTO shaft with the implement. The range of the EPG GROUP PTO shafts includes 9 sizes of different dimensions according to the power to be transferred . The sizes of the EPG GROUP PTO shafts and the power that can be transferred at 540 rpm are : SIZE 1 up to 16HP SIZE 2 up to 21HP SIZE 3 up to 30 HP SIZE 4 up to 35HP SIZE 5 up to 47HP SIZE 6 up to 60HP SIZE 7 up to 70HP SIZE 8 up to 90HP SIZE10 up to 110HPoler and leak free, compared with conventional worm gear units.

- Color:

-

Green;Blue;Custom

- ZQ Reducer gearbox:

-

ZQ Reducer

- gearbox:

-

Reducer gearbox

- gearbox for material:

-

gearbox for dryer

- Gear speed reducer:

-

Zq gear speed reducer

- Material:

-

45C Steel

Packaging & Delivery

-

Lead Time

: -

Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country.

Quantity(Pieces) 1 – 100 >100 Est. Time(days) 20 To be negotiated

Online Customization

Product Description

ZQ Cylindrical gear reducer gear carburizing, quenching, grinding, high bearing capacity, low noise; mainly used for belt conveyor and various kinds of transport machinery, can also be used to drive other general machinery. It has the advantages of high bearing capability, long service life, small volume, high efficiency, light weight, for the input shaft and the output shaft is vertically arranged in the driving device.

The field of cylindrical gear reducer is widely used in metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment etc..

|

Specification |

Manufacturing Capacity(t/h) |

Motor Power (kw) |

Pulley Speed (r/min) |

Gearbox Model |

Weight(t) |

|

Φ0.6×8 m |

1.5-2.8 |

4 |

8 |

JZQ 250-16- Ⅰ |

5.1 |

|

Φ0.8×10 m |

3 |

4 |

7.5 |

JZQ 350-16- Ⅰ |

6.9 |

|

Φ10×10 m |

3.3-4.9 |

5.5 |

5.8 |

JZQ 400-16- Ⅰ |

7.5 |

|

Φ1.2×10 m |

4-6 |

7.5 |

4.8 |

ZL 50-16- Ⅰ |

13.5 |

|

Φ1.5×12 m |

4-6 |

10 |

4.8 |

JZQ 500- Ⅲ-2F |

18.9 |

|

Φ1.5×15 m |

7-12 |

18.5 |

4.8 |

ZQ 500- Ⅲ-2F |

21 |

|

Φ1.8×12 m |

7-12 |

18.5 |

4.1 |

JZQ 50-16 Ⅱ-2 |

22.83 |

|

Φ2.2×12 m |

12 |

18.5 |

3.2 |

JZQ 650- Ⅲ |

37.6 |

|

Φ2.2×14 m |

12 |

22 |

3.2 |

JZQ 650- Ⅲ |

40 |

|

Φ2.2×16 m |

10-13 |

30 |

3.2 |

JZQ 750- Ⅲ |

45 |

|

Φ2.4×14 m |

10-14 |

30 |

3 |

JZQ 750- Ⅲ |

51 |

|

Φ2.4×18 m |

25 |

37 |

3 |

ZL85-13-Ⅰ |

54 |

|

Φ2.4×20 m |

32-36 |

37 |

3 |

ZL 85-13- Ⅰ |

54.14 |

|

Φ3×20 m |

40-50 |

55 |

2.59 |

ZL 100-16- Ⅰ |

78 |

|

Φ3×25 m |

45-58 |

75 |

2.59 |

ZL 100-16-I |

104.9 |

Zq Cylindrical gear speed reducer

Zq Cylindrical gear speed reducer is a three-level transmission of involute cylindrical gear reducer, mainly used inmining, metallurgy, cement, construction, chemical industry, light industry, etc all kinds of mechanical equipment, reduction drive, is suitable for the workplace being limited by the structure adopts the vertical installation, high-speed spindle speed not more than 1500 r/min, the work environment to + 40 °C and 40 °C -, can positive &negative operation.

Main Features

1.gear with high strength and low carbon alloy steel by carburizing quenching, tooth surface hardness of HRC58-62, gear are CNC grinding process, high precision, good contact.

2.transmission rate is high: single stage is greater than 96.5%, double stage is greater than 93%, grade three is greater than 90%.

3.stable operation, low noise.

4.small size, light weight, long service life, high carrying capacity.

5.easy to be disassembled and easy to install.

Our Company

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for ….

Application area

Certifications

Sales territory

Packing & Delivery

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZheJiang China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Contact us

Mobile: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Add:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd.

Best China manufacturer & factory SLP in Erbil Iraq series fflange planetary speed reducer helical gearmotor line transmission 1:80 ratio speed reducer gearbox screw jack With high quality best price

Service & Quality controlWe supply detailed drawings and offer whenever necessary.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms

- Place of Origin:ZhejiangBUILDING ON LEADERSHIP IN INNOVATION Our investments in research and development significantly exceed the industry average. This is a result of our distinctive culture of innovation., China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

Up to 260000Nm

- Input Speed:

-

750-1500rpm

- Output Speed:

-

0.19-60rpm

- Certification:

-

ISO9001-2008

- Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country. Mount Position:

-

Foot Mounted

- Bearing:

-

C & U

- gear precision grade:

-

din 4

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard wooden case

- Port

- Ningbo Port, Shanghai Port

Online Customization

Product Description

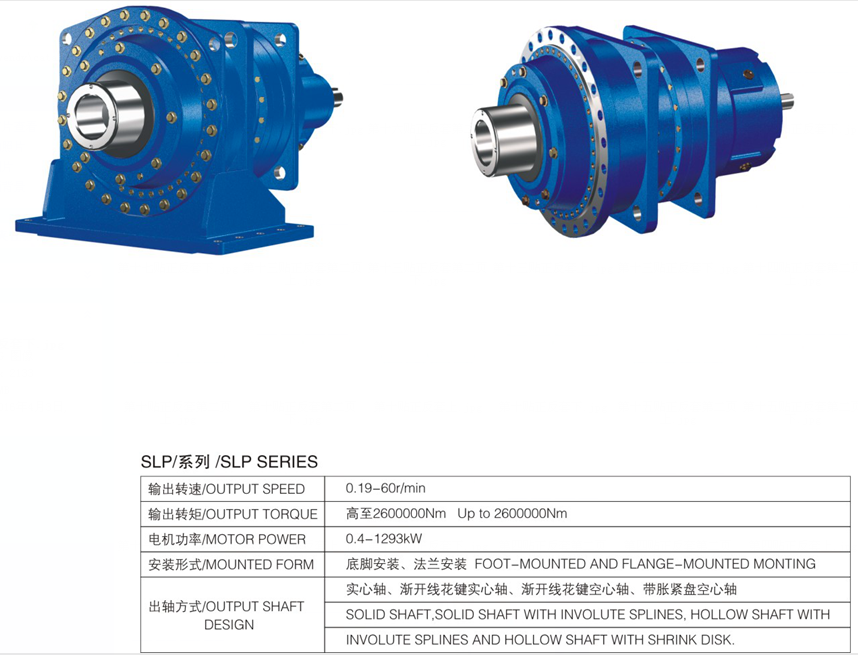

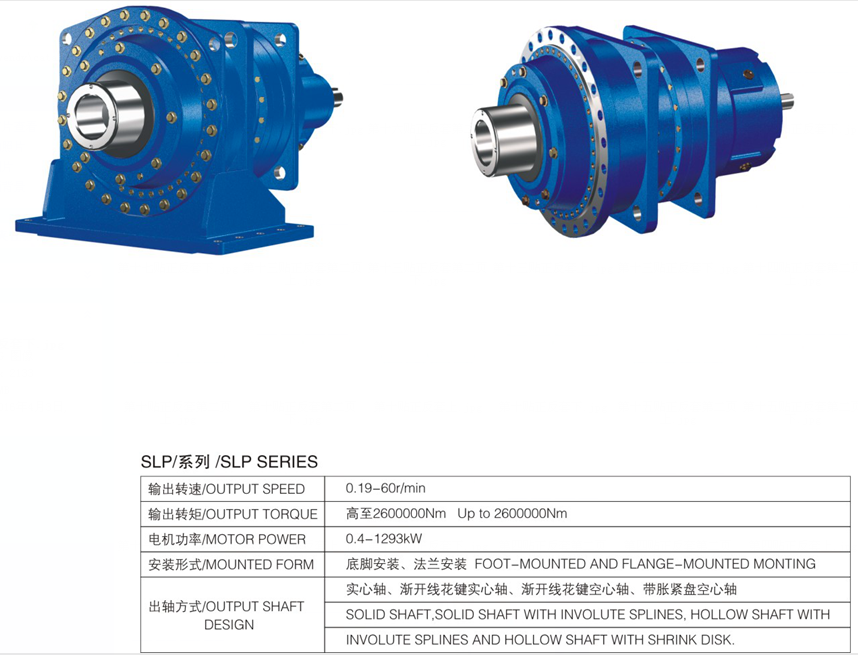

SLP series fflange planetary speed reducer helical gearmotor line transmission jack screw actuator wpa reducer

Advantage:

SLP series planetary speed reducer has the features of light weight, small volume, high transmission ratio, high efficiency, smooth rotation, low noise and good applicability.

1) Output speed:0.19~60r/min

2) Output torque: up to 260,000N.m

3) Motor power: 0.4~1293kW

4) Mounted form: foot-mounted ,flange-mounted

Main application:

Mixers / Agitator,Roller presses,Conveyor drives,Shredders ,Filtration technology,Water treatment,Reactors,Travel drives,Feeder,Mill

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series HigSlip clutch type on the rotary tiller, again slight oozing of grease on the UJ, do not grease the clutch; these run dry and should be “slipped” at least once a year to prevent rusting togetherh Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

Export near me made in China – replacement parts – in Gebze Turkey to Malaysia Market Pipe Rubber Reducer Flexible Couplings with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 distinct branches. For a lot more details: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Merchandise Description

Characteristics: iron grooved coupling

1) Substance: ductile ca EPT iron ASTM-A536

2) Minimizing installation costs

3) Adaptability and rigidity

4) Joint reliability

5) Isolate sounds and vibration

6) Convenient joint

7) Application: Electricity plant Heating,ventilation and air conditioning Industrial plant H2o therapy Plumbing Fire defense Mining and mine processing Oil area Maritime. This kind of coupling is made for the pipe bearing reasonable strain. It allows managed angle, linear and rotational motion at every joint and gives the additional positive aspects of expansion, contraction and deflection. This is usful to accommodate uneven laying surfaces, and motion from thermal alterations, placing, seismic effect or EPT triggers. Flexible coupling can be used in hearth security technique, feed drinking water, gasoline system and and so forth.

Dimension Sheet

The world’s mo EPT sophisticated automatic disa molding line and sand processing ensure the good quality of every product.

Tilting shot blasting machine

Test

In purchase to guarantee the high quality, the business released German brand spectrograph, innovative KRX-TG, Metallographic graphic analyzer, gasket te EPT products, eco-friendly sand te EPT products, ca EPT iron assay analysis products, force inspection equipment and many others. Thus a quickly, accurate quantitative examining technique is provided for scale production

FAQ

Q: Are you investing firm or maker ?

A: We are a manufacturing unit.

Q: How lengthy is your supply time?

A: Usually fifteen days after the down payment. EPT thirty to 90 times.

Q: Do you offer samples ? is it free of charge or additional ?

A: Of course, we could offer the sample for free demand but do not pay the co EPT of freight.

Q: What is your conditions of payment ?

A: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 30% T/T in progress ,equilibrium prior to shippment.

If you have an EPT query, p EPT truly feel cost-free to speak to us.

Our advantages:

1: Globally acceptabe quality: The products offered by us are thoroughly examined by our experienced professionals to ensure their durability, reliability and long service life.

two:Competitive price: direct manufacturer, reducing all unnecessary cost for you.

3:Professional team:20 years foreign customers service experience. Over 10 years investment casting manufacture. Almost 35% high educated people.

four:Good service: Customer is first

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 diverse branches. For far more details: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original tools manufacturer’s (OEM) element figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our business and the outlined substitute components contained herein are not sponsored, approved, or produced by the OEM.