Product Description

SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Description:

SWC-WD-type cross shaft universal coupling is 1 of the most common coupling. With its characteristic structure enables not on the same axis or the axis angle greater or axial movement of a larger two-axis continuous constant angular velocity rotation, and reliably transmit torque and motion. Can be widely used in metallurgy, lifting, engineering, transportation, mining, oil, shipbuilding, coal, rubber, paper machinery and other heavy machinery industry, mechanical shafting transmitting torque.

Advantages:

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Product parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Signs of Wear or Damage in a Cardan Coupling and Detection Methods

Over time, cardan couplings can experience wear or damage that may impact their performance. Some common signs of wear or damage include:

- Vibration: Excessive vibration during operation can indicate misalignment or worn components in the cardan coupling.

- Noise: Unusual noises such as clunking, knocking, or rattling can indicate worn bearings or other components.

- Increased Play: If there is noticeable play or backlash in the coupling, it may suggest worn or loose components.

- Reduced Performance: A decrease in torque transmission or power transfer efficiency can indicate wear in the coupling.

- Leakage: In the case of lubricated cardan couplings, leakage of lubricant may occur due to worn seals or damaged components.

To detect these signs of wear or damage, various methods can be employed:

- Visual Inspection: Regularly inspect the coupling for any visible signs of wear, corrosion, or damage.

- Vibration Analysis: Use vibration analysis tools to monitor vibration levels and detect any irregularities.

- Noise Analysis: Listen for unusual noises during operation, which may indicate worn or misaligned components.

- Torque Measurement: Monitor the torque transmitted through the coupling and compare it with expected values.

- Play Measurement: Check for any play or backlash in the coupling by manually moving the shafts.

- Lubricant Analysis: Analyze the condition of the lubricant for any contamination or signs of wear.

Regular maintenance and inspections are crucial for detecting and addressing wear or damage in cardan couplings before they lead to more severe issues or failures.

Challenges and Alignment of Cardan Couplings

Cardan couplings, while capable of accommodating angular misalignment, can pose certain challenges related to alignment. Here’s an overview of these challenges and how they can be addressed:

1. Angular Misalignment Limit: Cardan couplings have a limit to the amount of angular misalignment they can accommodate without causing excessive wear and vibration. It’s essential to stay within the manufacturer’s specified misalignment range.

2. Precision Assembly: Assembling a cardan coupling requires precision to ensure that the yokes and spider are aligned correctly. Misaligned assembly can lead to premature wear and increased vibrations.

3. Balancing and Vibration: Cardan couplings can introduce imbalances due to their design. Imbalances can result in vibration and reduce the overall efficiency of the system.

4. Lubrication: Adequate lubrication is crucial to minimize friction and wear in the bearings of the spider. Poor lubrication can lead to increased heat generation and accelerated wear.

5. Maintenance: Regular maintenance is required to monitor the condition of the coupling, including checking for wear, misalignment, and any signs of damage.

6. Torque Fluctuation: In applications with significant angular misalignment, cardan couplings may experience torque fluctuations due to the changing angles of the shafts.

To address these challenges:

– Follow the manufacturer’s guidelines for installation, alignment, and maintenance.

– Use precision tools and techniques during assembly to ensure proper alignment.

– Balance the rotating components to minimize vibration.

– Maintain proper lubrication to reduce friction and wear.

– Periodically inspect the coupling for wear, misalignment, and signs of damage.

– Consider using flexible couplings with higher misalignment capabilities for applications with extreme misalignment requirements.

Proper alignment, maintenance, and adherence to manufacturer recommendations can help maximize the efficiency and longevity of cardan couplings in mechanical systems.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-04-17

China Hot selling SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Product Description

SWC-Wd Type Cardan Shaft Coupling Transmission Speed Reducer Universal Shaft Coupling for Gear Box

Description:

SWC-WD-type cross shaft universal coupling is 1 of the most common coupling. With its characteristic structure enables not on the same axis or the axis angle greater or axial movement of a larger two-axis continuous constant angular velocity rotation, and reliably transmit torque and motion. Can be widely used in metallurgy, lifting, engineering, transportation, mining, oil, shipbuilding, coal, rubber, paper machinery and other heavy machinery industry, mechanical shafting transmitting torque.

Advantages:

1. The ability to have a large angle compensation.

2. The structure is compact and reasonable. SWC-WD type with integral fork, so carrying more reliable.

3. The carrying capacity. Compared with other types of the same diameter rotary joint axis, it delivers more torque, the turning diameter of restricted mechanical equipment, the complete range is more advantageous.

4. High transmission efficiency. Its transmission efficiency of 98-99.8% for high-power transmission, energy-saving effect.

5. carrying smooth, low noise, easy maintenance, assembly and disassembly.

Product parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Lubricating and Maintaining Cardan Couplings

Proper lubrication and maintenance are crucial for ensuring the reliable and efficient performance of cardan couplings. Here are some best practices to follow:

- Lubrication: Use a high-quality lubricant recommended by the manufacturer. Regularly lubricate the universal joints and other moving parts to reduce friction, wear, and heat generation.

- Inspection: Periodically inspect the coupling for signs of wear, corrosion, or damage. Check for loose bolts, misalignment, or any abnormalities that could affect performance.

- Alignment: Maintain proper alignment and phasing of the universal joints. Incorrect alignment can lead to premature wear and vibrations.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening bolts and fasteners. Over-tightening or under-tightening can lead to issues.

- Cleanliness: Keep the coupling and surrounding area clean from debris, dirt, and contaminants that could affect the coupling’s operation.

- Temperature: Be mindful of the operating temperature of the coupling. Extreme temperatures can affect the lubricant’s properties and cause premature wear.

- Regular Maintenance: Implement a regular maintenance schedule that includes lubrication, inspection, and any necessary adjustments. This helps identify and address issues before they escalate.

- Replacement Parts: When replacing components, use genuine parts from the manufacturer to ensure compatibility and performance.

- Training: Ensure that personnel responsible for maintaining the coupling are trained in proper procedures to avoid mistakes and ensure safety.

By following these best practices, you can extend the lifespan of your cardan couplings, maintain efficient power transmission, and minimize downtime due to unexpected failures.

Industry Standards and Guidelines for Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are widely used components in various industries. While there might not be specific standards solely dedicated to cardan couplings, they are often designed and manufactured in accordance with relevant industry standards and guidelines related to mechanical power transmission. Some of these standards include:

ISO Standards:

– ISO 9001: Quality management systems.

– ISO 1308: Tolerances for rolling bearings.

– ISO 10100: Principles for design of rotating machinery.

AGMA Standards:

– AGMA 9005: Selection of Lubricants for Enclosed Gear Drives.

– AGMA 6034: Gear Inspection Handbook: Guidelines and Methods for Inspection of Tooth Flanks, Gear Blank Dimensions, and Gear Quality Control.

API Standards:

– API 671: Special-Purpose Couplings for Petroleum, Chemical, and Gas Industry Services.

ASME Standards:

– ASME B106.1: Power Transmission Couplings, Elastomeric and Steel Double Flexing.

Additionally, manufacturers and users of cardan couplings often follow best practices and guidelines provided by engineering organizations and associations specific to their industries. It’s important to ensure that the cardan couplings are designed, manufactured, and installed in compliance with relevant standards and guidelines to ensure their safe and efficient operation.

What are the key features and benefits of using a cardan coupling?

Cardan couplings, also known as universal joints or U-joints, offer several key features and benefits that make them valuable components in various mechanical systems:

- Angular Misalignment Compensation: One of the primary features of cardan couplings is their ability to accommodate angular misalignment between shafts. This flexibility allows them to transmit torque even when the input and output shafts are not collinear.

- Torque Transmission: Cardan couplings are effective in transmitting torque between shafts at an angle. They can handle both small and moderate torque loads, making them suitable for a wide range of applications.

- Compact Design: The simple and compact design of cardan couplings makes them easy to integrate into various mechanical systems without requiring excessive space.

- Cost-Effective Solution: Cardan couplings provide a cost-effective solution for transmitting torque in cases of angular misalignment. Their straightforward design and manufacturing process contribute to their affordability.

- High-Speed Transmission: Cardan couplings can handle high rotational speeds, making them suitable for applications where rapid motion and torque transmission are required.

- Versatility: These couplings find applications in diverse industries, including automotive, industrial machinery, agriculture, and aerospace, due to their ability to compensate for misalignment and transmit torque effectively.

- Reduced Vibrations: In some cases, cardan couplings can help dampen vibrations and shocks that may occur due to misalignment, contributing to smoother operation.

- Simple Maintenance: Maintenance of cardan couplings typically involves lubrication of the bearing and regular inspection for wear and tear. This maintenance process is relatively straightforward and can extend the component’s lifespan.

- Easy Replacement: If a cardan coupling needs to be replaced due to wear or failure, its simple design makes the replacement process relatively quick and uncomplicated.

Overall, the key features and benefits of using cardan couplings make them an attractive choice for applications where torque transmission and angular misalignment compensation are necessary.

editor by CX 2024-04-15

China manufacturer & factory supplier for wenzhou in West Yorkshire United Kingdom coaxial transmission speed reducer motor engine spiral transmission lifting equipment steering gear box lifting jack With high quality best price & service

ISO 9001:2015 certified producer and distributor of roller chains. Kinds of roller chains contain ASME/ANSI standard chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, totally free-movement chains, specialty chains and British common chains. ASME/ANSI standard chains are obtainable in massive and tiny pitch, double pitch and leaf styles. Roller chains are utilised in meals packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and electricity transfer applications.We have exported our goods to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states of america, Canada, and many others.

Overview

Quick Particulars

- Applicable Industries:

-

Manufacturing Plant, Machinery Fix Stores, Foods & Beverage Factory, Farms

- Area of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Velocity:

-

1400rpm

- Output Speed:

-

fourteen-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Place:

-

Foot Mounted

- Bearing:

-

LYC,SKF

Source Potential

- Supply Capacity:

- five hundred Unit/Models for every Month

Packaging & Shipping and delivery

- Packaging Particulars

- Wood containers , Cantons packed in 1 pallet

Our goods is well-liked exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, more than sixty countries and regions.

- Port

- Ningbo Port, Shanghai Port

On-line Customization

Item Description

SLR helical reducer has the features of large versatility,very good blend and weighty loading functionality, alongside with other merits this kind of as straightforward to achieve a variety of transmission ratios, high performance, reduced vibrationand large permissible axis radial load. This series can not only be combined with a variety of kinds of reducers and variators and meet the requirements, but also beadvantage of localization of relevant transmission tools.

Requirements:

1) Output pace: .6~1,028r/min

2) Output torque: up to eighteen,000N.m

three) Motor energy: .eighteen~160kW

4) Mounted kind: foot-mounted and flange-mounted mounting

|

Product Identify |

SLR Collection Rigid Tooth helical reducer |

|

Equipment Material |

20CrMnTi |

|

Situation Substance |

HT250 |

|

Shaft MaterialA power just take-off or power takeoff (PTO) is any of several strategies for having power from a power supply, such as a operating motor, and transmitting it to an application this kind of as an attached apply or separate device. |

20CrMnTi |

|

Equipment Processing |

Grinding end by HOFLER Grinding Equipment |

|

Color |

Custom-made |

|

Sounds Check |

Bellow 65dB |

Certifications

Trade Exhibits

Packaging & Transport

Packing Details : Standard carton/Pallet/Standard wooden case

Shipping Specifics : 15-thirty woOur stepper and BLDC motors, linear actuators and linear positioning drives, in dimensions commencing at 10 mm, collectively with a variety of gearboxes and encoders, blend into a modular system with above 4000 attainable combinations. In addition, you can pick from a selection of shaft, flange and connector varieties that quickly and reliably link to current unit architecture. The efficiency and resonance actions of EPG motors is optimized by smart motor controllers that meet the latest technological innovation expectations.rking times on payment

Firm Info

other collection item

| Precision Planetary gearbox | Robotic RV gearbox pace reducer |

| Personalized created Non-normal Gearbox | UDL Collection Variator |

| PYZ Sequence Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Collection Planetary Reducer | SLH/SLB Series High Electricity Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Collection Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Related Products

Speak to

Best China manufacturer & factory K series right angle flange mounted helical-bevel gear speed reducer ac motor gear box reducer conveyor With high quality best price

In 2000, EPG took the lead in gaining ISO14001 environment management certificate and thereafter passed the inspection of clean production and recycling economy, winning the title of “Zhejiang Green Enterprise”.

Overview

Quick Details

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining, Construction works

- Place of Origin:Zhejiang, China

-

PTO Shaft A PTO Adapter will be useful when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could cause the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 point hitch.

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

10~62800N.m

- Input Speed:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

5.36~197.37

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC, HRB,ZWZ,NSK

- Warranty:

-

12 Months

Supply Ability

- We have divided our product portfolio into two areas in order to meet very different requirements: in the high-end segment, we focus on technology and performance, while in the general segment, cost-effective and high-demand products are the main focus. Supply A”EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. bility:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

K Series right angle flange mounted helical-bevel reducer ac motor gear box reducer sew conveyor

Product Description

SLK series gearbox is one kind of Helical Bevel type gearbox , High-stainless cast iron case . ,it is designed based on modularization , which bring many difference kinds of combinations ,mounting types ,and structure designs .The detail classification of ratio can meet various of working condition .High Transmission efficiency ,Low energy consumption, superior performance . The hard tooth surface gear use the high quality alloy steel , the process of carburizing and quenching, grinding ,which give it follow characters : Stable transmission , low noise and temperature ,high loading ,long working life. which widely use for industry equipment of metallurgy ,Building Material , Chemical , Mining , Oil, Transportation , Papermaking , Sugar making , engineering Machines ,etc

Specifications:

1) Output speed: 0.6~1,028r/min

2) Output torque: up to 21700N.m

3) Motor power: 0.12~200kW

4) Mounted form: foot-mounted and flange-mounted mounting

|

Product Name |

SLK Series Rigid Tooth helical bevel reducer |

|

Gear Material |

20CrMnTi |

|

Case Material |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines |

|

Color |

Customized |

|

Noise Test |

65~70dB |

|

Efficiency |

94%~98% (depends on the transmission stage) |

|

Lubricating oil |

Shell Omala synthetic oil or mineral oil , or similar brand |

|

Heat treatment |

tempering, cementiting, quenching,etc. |

|

Brand of bearings |

C&U bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

|

Brand of oil seal |

NAK or other brand |

|

Temp. rise (MAX) |

40 ° |

|

title |

helical motor bevel geared,sew gear motor |

|

Temp. rise (Oil)(MAX) |

50 ° |

|

Vibration |

≤20µm |

Company Information

Certifications

Our Services

Packaging & Shipping

Expo& Customers

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us

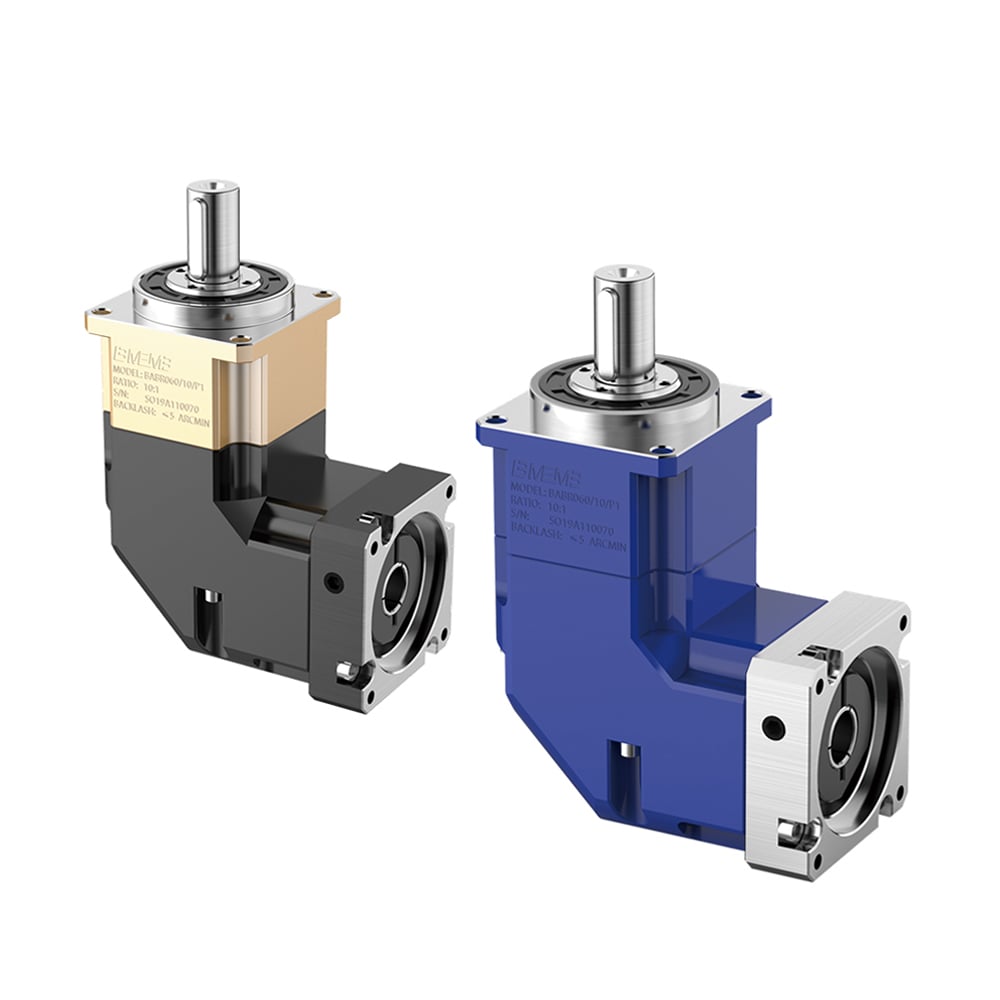

china Lowest price manufacturer BABR115 speed reducer planetary transmission gear box for mixer

EPG will usually adhere to it company spirit of being practical, progressive, successful and excellent to make the top international transmission generate.

Overview

Quick Details

- Relevant Industries:

-

CNC

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

195~325N.m

- Input Pace:

-

4000rpm

- Output Velocity:

-

*

- Place of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Merchandise identify:

-

precision planetary appropriate angle gearbox

- Materials:

-

20CrMnTi, 40Cr

- Ratio:

-

three~200

- Backlash:

-

P1/P2

- Ingress security:

-

IP65

- Color:

-

champagne gold+black/ silver+blue/ OEM coloration

- Heat treatment method:

-

hot cast/hardening

Offer Potential

- Offer Potential:

- 200000 Piece/Pieces for every Thirty day period

Packaging & Shipping

- Port

- Ningbo/Shanghai/ China Port

-

Guide Time

: -

Amount(Items) one – 1000 >1000 Est. Time(days) thirty To be negotiated

On the internet Customization

Ever-electricity Team Co., Ltd. is Specialist IN Making ALL Sorts OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Speed REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Auto GEARBOXES, PTO Travel SHAFTS, Particular REDUCER & Connected Gear Elements AND OTHER Related Items, SPROCKETS, HYDRAULIC Program, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Low BACKLASH WORM REDUCERS AND SO ON. Furthermore, WE CAN Create Custom-made VARIATORS, GEARED MOTORS, Electric powered MOTORS AND OTHER HYDRAULIC Products In accordance TO Customers DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional maker ofgearbox and motors.The factory covers an region of 20,000 square meters, the constructing spot of 30,000 square meters, the total variety of workers is more than two hundred .We have handed theISO9001:2015intercontinental top quality administration system common certificate,CCCnationwide obligatory product certificate andCEcertification . We have produced advanced management software program such asERPto hold tempo with global common.In get to serve customers better the business actively cooperates with colleges and universities to create new products and improve current items .

|

Q1. Are you trading business or maker? A. We are producer Located in Taizhou Metropolis of East China. Q2. How is guarantee of the high quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled examine and document content and semi-concluded spare parts. And – one hundred% inspect concluded spare components ahead of set in storage. – a hundred% inspect prior to assembly. – 100% inspect ahead of packaging. Q3. What details shall we give ahead of placing a obtain order? We can provide technological assist and the drawing according to your need if you speak to with me. This autumn. What industries are your gearboxes becoming used? Our gearboxes are extensively employed in the regions of textile, meals processing, beverage, chemical sector,escalator,automatic storage products, metallurgy, tabacco, environmental defense, logistics and etc. Q5. Do you have warranty support? Of course, the gearbox is totally free warranty inside of 1 years right after shipping. |

||||||